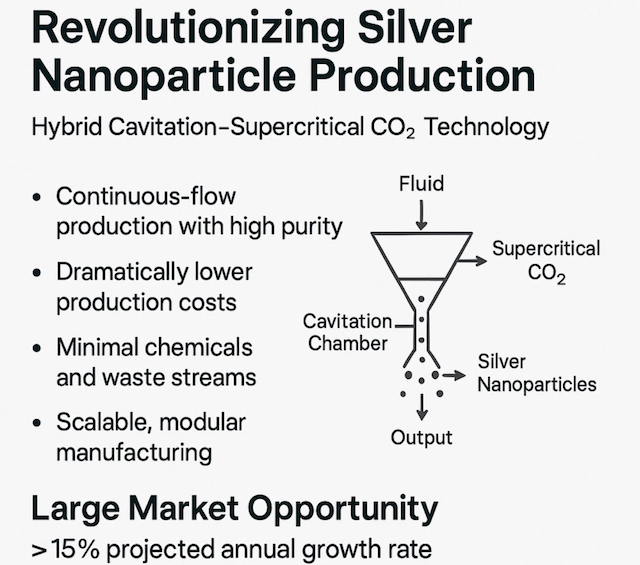

Revolutionizing Silver Nanoparticle Production with Hybrid Cavitation–Supercritical CO₂ Technology

Executive SummarySilver nanoparticles represent one of the fastest-growing categories of high-value advanced materials, used in electronics, medical devices, antimicrobial coatings, energy systems, catalysts, and sensors. Despite their strategic importance, production methods today remain slow, expensive, chemically intensive, and difficult to scale. Industrial adoption is constrained by high operating costs, inconsistent particle sizes, and complex purification stages.A new hybrid process that combines hydrodynamic cavitation with supercritical CO₂ (sCO₂) fundamentally changes the economics and scalability of nanoparticle manufacturing. This integrated system enables continuous-flow production with extreme uniformity, solvent-free extraction, and sharply reduced operational overhead. For investors, the technology represents a rare opportunity to enter a high-margin, unserved market with defensible engineering advantages and rapid scalability.Market OpportunityThe global silver nanoparticle market exceeded USD 2.5 billion and is projected to grow at over 15 percent annuallydue to accelerating demand in:• Medical and antimicrobial technologies• Semiconductor and electronics manufacturing• Batteries, catalysts, and energy systems• Coatings, inks, and 3D-printing conductives• Environmental remediation and filtrationCurrent production constraints keep prices high, often $10 to $45 USD per gram, with limited ability to meet large-volume, high-purity orders.The hybrid cavitation–sCO₂ platform addresses these bottlenecks and moves the market toward industrial scale at significantly lower cost.The Technology AdvantageHydrodynamic CavitationCavitation occurs when fluid pressure drops rapidly, forming vapor bubbles that violently collapse. This creates localized conditions of:• Temperatures near 5,000 K• Pressures exceeding 1,000 atmospheres• Extreme micro-mixing and shear forcesThese effects produce highly uniform silver nuclei at nanosecond timescales, allowing unparalleled control of particle formation without chemical stabilizers or complex reagents.Supercritical CO₂ ExtractionAfter nucleation, particles enter a high-density sCO₂ environment. Supercritical CO₂ offers:• Tunable solvent properties• Oxygen-free stabilization• Rapid drying and solvent-free extraction• Elimination of waste streamsThe result is dry, high-purity, uncontaminated silver nanoparticles directly from the reactor, without filtration, washing, or chemical cleanup.Cost Disruption: A Transformational Economics ModelThe hybrid system reduces production cost per gram by 60 to 75 percent compared to traditional methods.Estimated Production Costs• Traditional Chemical Reduction: 4.50 to 7.00 USD per gram• Thermal / Photochemical: 5.00 to 8.50 USD per gram• Hybrid Cavitation–sCO₂: 1.10 to 2.00 USD per gramThis cost advantage is driven by:• Minimal chemical inputs• No stabilizers or solvents required• Continuous-flow operationExtremely low purification overhead• Low energy use compared to thermal systems• High yield with near-zero wasteIn markets selling at 10 to 45 USD per gram, the margin potential is substantial.Scalability and Deployment StrategyModular Production UnitsEach cavitation–sCO₂ system operates as a compact module, enabling:• Rapid deployment• Manufacturing at distributed or centralized facilities• Numbering-up rather than scaling-up• Fast doubling of capacityThis mirrors proven modular scale strategies used in semiconductor, chemical, and data-center infrastructure markets.Operational Benefits• Minimal labor requirements• Predictable quality control• Extremely high uptime• Fully enclosed, low-risk processing• Environmentally clean operation suitable for ESG-aligned investmentsIntellectual Property and Competitive PositioningThe hybrid system occupies a defensible engineering niche where:• Cavitation physics• CO₂ phase control• Continuous nanoparticle precipitation• Solvent-free extractioncombine into a process that traditional chemical producers cannot replicate at scale.This creates strong barriers to entry and favorable licensing opportunities.Revenue ModelsMultiple revenue strategies can be applied:• Direct Sales of NanoparticlesHigh-margin materials at industrial pricing.• Equipment LicensingLicensing cavitation–sCO₂ modules to materials manufacturers.• Contract ManufacturingServing medical, electronics, and aerospace clients.• Private-Label ProductionSupplying silver nanopowders under client brands.• Technology Royalty AgreementsAllowing global scaling without heavy capital expenditure.Investment CaseThe hybrid cavitation–supercritical CO₂ system is positioned to become a new standard in nanoparticle manufacturing, offering:• Lower costs• Higher purity• Faster production• Environmentally clean operation• Strong IP defensibility• Modular, scalable growthInvestors gain exposure to a high-growth advanced materials market with clear differentiation, high-margin potential, and global applicability across multiple industries.