|

Hydrodynamic Cavitation vs Supercritical CO2 Processing for Silver Nanoparticles

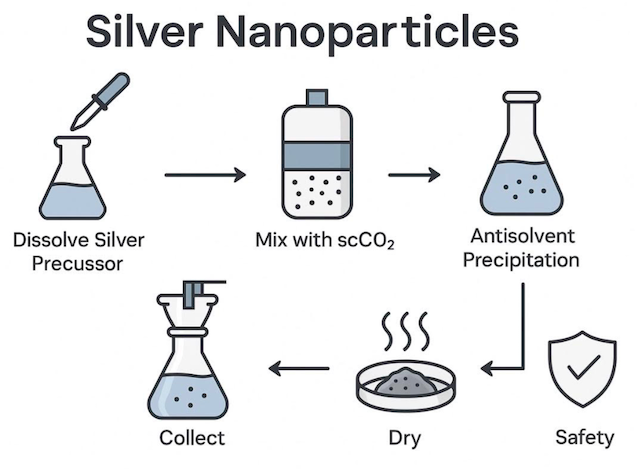

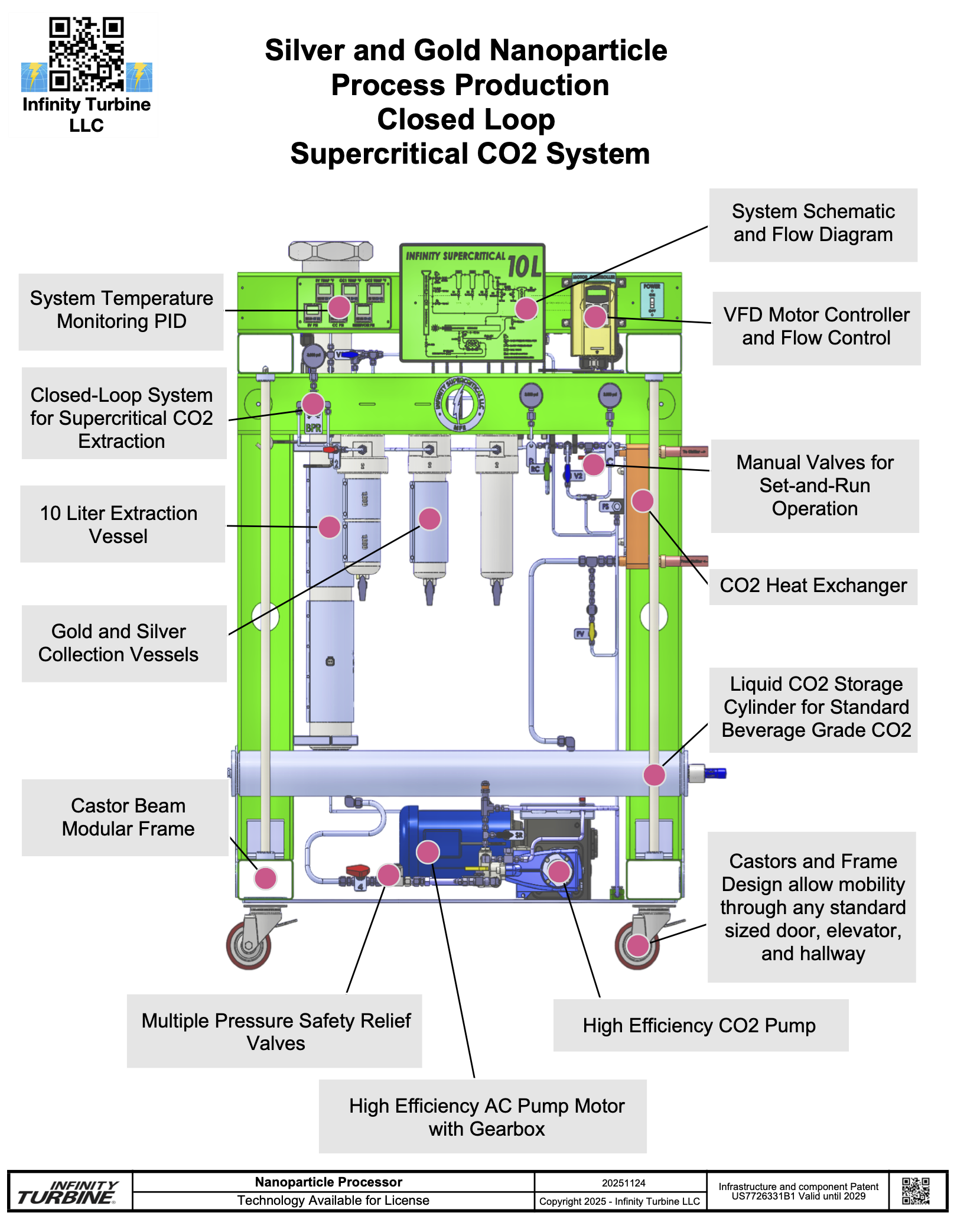

1. IntroductionSilver nanoparticles sit at a profitable crossroads between materials science and real products: antimicrobial coatings, filtration, textiles, conductive inks, and medical devices. There are many ways to make nano silver, but two modern methods stand out for process intensification and greener chemistry:1. Hydrodynamic cavitation2. Supercritical CO2 based nanoparticle processingBoth can, in principle, produce similar end products, but they are built on very different physics and plant infrastructure. Choosing between them (or combining them) depends on what you value most: low capex and throughput, or precision, cleanliness, and high-value markets.This article compares hydrodynamic cavitation versus supercritical CO2 processing specifically for silver nanoparticle production.2. Hydrodynamic cavitation for silver nanoparticles2.1 How it worksHydrodynamic cavitation uses a liquid (typically water or an aqueous solution) forced through a constriction such as:• Orifices• Venturi nozzles• Vortex cavitation devicesThe rapid local pressure drop creates vapor cavities (microbubbles) that collapse violently downstream. These collapses generate:Localized high temperatures and pressuresIntense shear and micro-jettingStrong mixing on very short time scalesFor silver nanoparticle synthesis, the process usually involves:1. Dissolving a silver salt in water (for example silver nitrate).2. Adding a reducing agent or relying on cavitation-driven radical chemistry to reduce Ag⁺ to Ag⁰.3. Using stabilizers or capping agents to control particle growth and prevent aggregation.4. Circulating the slurry through the cavitation device until the desired particle size is reached.2.2 Strengths• Relatively low capital cost compared to high-pressure CO2 systems.• Uses water as the primary medium, which is cheap and familiar.• Good for continuous or semi-continuous processing.• Strong mixing and energy input can drive fast reactions and nucleation.2.3 Limitations• Particle size distribution can be broader unless carefully tuned.• Residual salts, by-products, and stabilizers remain in the liquid and need downstream purification.• Process conditions are less finely tunable than in a high-pressure CO2 system.• Handling and disposal of aqueous waste streams containing silver and chemicals adds environmental and regulatory complexity.Hydrodynamic cavitation is attractive when:You aim for moderate-cost, moderate-spec nano silver.You prioritize simple hardware and higher throughput over ultra-precise control.3. Supercritical CO2 processing for silver nanoparticles3.1 How it worksSupercritical CO2 (sCO2) methods rely on CO2 above its critical point (about 31 degrees Celsius and 73 bar), where it behaves like a gas and liquid simultaneously. Depending on the process, sCO2 can act as:• A solvent• An antisolvent• A transport medium for precursorsTypical routes for silver nanoparticles include:1. Supercritical antisolvent (SAS)Dissolve a silver precursor or complex in an organic solvent.Inject this solution into flowing sCO2.The CO2 collapses solvent power, forcing silver-containing species to precipitate as fine particles.Particles are collected on filters or substrates; CO2 and solvent are recovered.2. Impregnation and in situ reduction• Use sCO2 to transport silver precursors into porous supports (filters, textiles, polymer foams).• Change conditions or add reducing agents so silver nanoparticles form inside the substrate.3. RESS (rapid expansion of supercritical solutions), in special cases where the precursor is CO2-soluble.3.2 Strengths• Very fine control over pressure, temperature, and flow leads to narrow particle size distributions.• CO2 leaves essentially no residue; final powders can be very clean.• Easy to integrate impregnation and coating: you can directly produce nano-silver-functionalized filters, membranes, or textiles.• The process aligns well with green and low-solvent messaging, since CO2 is recycled.• Higher value markets (medical, high-end coatings) often favor such clean and controllable processes.3.3 Limitations• Higher capital cost: high-pressure vessels, pumps, and controls.• Requires skilled operation and process development.• Batch or semi-batch in many setups, though continuous systems are possible.• Organic solvents and ligands may still be required in some recipes, even if overall solvent use is reduced.Supercritical CO2 processing is attractive when:• You target high-value, high-specification silver nanoparticle products.• You want to emphasize purity, tight size control, and clean processing in your marketing.4. Head-to-head comparison4.1 Product quality and controlHydrodynamic cavitation• Good for creating nanoparticles but often with broader size distributions.• More variability unless carefully engineered.Supercritical CO2• Better control over nucleation and growth.• Easier to engineer narrow, repeatable particle size ranges and specific morphologies.If your market demands tight specs and consistency (medical, diagnostics, specialized electronics), sCO2 has the edge.4.2 Purity and downstream processingHydrodynamic cavitation• End product is a slurry containing salts, by-products, capping agents, and water.• Requires filtration, washing, and drying.Supercritical CO2• CO2 flashes off cleanly on depressurization.• Properly designed processes yield dry powders or coated substrates with less liquid waste.If you want minimal solvent handling and cleaner powders, sCO2 is more attractive.4.3 Capital cost and complexityHydrodynamic cavitation• Lower capex: pumps, cavitation device, tank, filters.• Easier for a small shop or emerging market to implement.Supercritical CO2• Higher capex: pressure-rated vessels, CO2 pumps, heat exchangers, high-pressure piping.• Requires more safety and controls engineering.For entry-level nanoparticle production at modest spec, hydrodynamic cavitation wins on cost. For multi-use, high-end R and D and production, sCO2 justifies the investment.4.4 Operating costs and scalabilityHydrodynamic cavitation• Energy cost is tied to pumping and pressure drop across the cavitation device.• Water and chemical costs can be modest, but waste handling adds to operating cost.Supercritical CO2• Higher energy cost per unit mass for compression and pumping.• CO2 itself is inexpensive and recyclable.• Good potential for scalable, recipe-driven production, especially if you use the same skid for other products (botanicals, other nanoparticles).If you see a path to multi-product use (extracts, nano metals, coatings, and more), the sCO2 system can amortize its cost across many revenue streams.4.5 Safety and environmental messagingHydrodynamic cavitation• Water-based but uses soluble silver salts, reducing agents, and stabilizers.• Environmental messaging is fine but must address silver-containing effluents.Supercritical CO2• Strong story: non-flammable, non-ozone-depleting CO2 as a working fluid, mostly recycled.• Lower liquid waste volumes; easier to pitch as a clean nano silver production method.For eco-branding and regulatory comfort, sCO2 has a strong marketing advantage.5. Strategic use casesYou can position the two technologies differently in a product and business roadmap.Hydrodynamic cavitation focus:Bulk or mid-grade antimicrobial nano silver for:• Coatings where exact particle size is less critical.• General textiles and plastics.• Price-sensitive markets.Selling point:Cost-effective, high-throughput nano silver production in water.Supercritical CO2 focus:High value application silver nanoparticles for:• Medical devices and wound dressings.• High-end filtration and membranes.• Conductive inks for fine-feature printed electronics.• Integrated nano-silver-coated substrates (filters, textiles, foams).Selling point:High purity, precisely engineered nano silver, made with a clean, scalable supercritical CO2 process.If you own both technologies (or integrate cavitation into pre or post-processing around an sCO2 core), you can address both ends of the market: cost-driven bulk, and performance-driven specialty.6. ConclusionHydrodynamic cavitation and supercritical CO2 processing are not competitors so much as complementary tools for silver nanoparticle production:• Cavitation is the workhorse: lower capex, good for bulk and mid-range quality.• Supercritical CO2 is the precision tool: higher capex, but with better control, cleaner product, and stronger environmental and quality narratives.For a business focused on high-margin, specialty nano silver products and multi-use processing (botanicals, other nanoparticles, coatings), a supercritical CO2 platform is particularly attractive. For cost-sensitive, high-volume antimicrobial markets, hydrodynamic cavitation may be the first step.Either way, silver nanoparticles offer a bridge between chemistry, engineering, and profitable niches—and choosing the right process lets you tune your product line to the markets you want to serve.

|