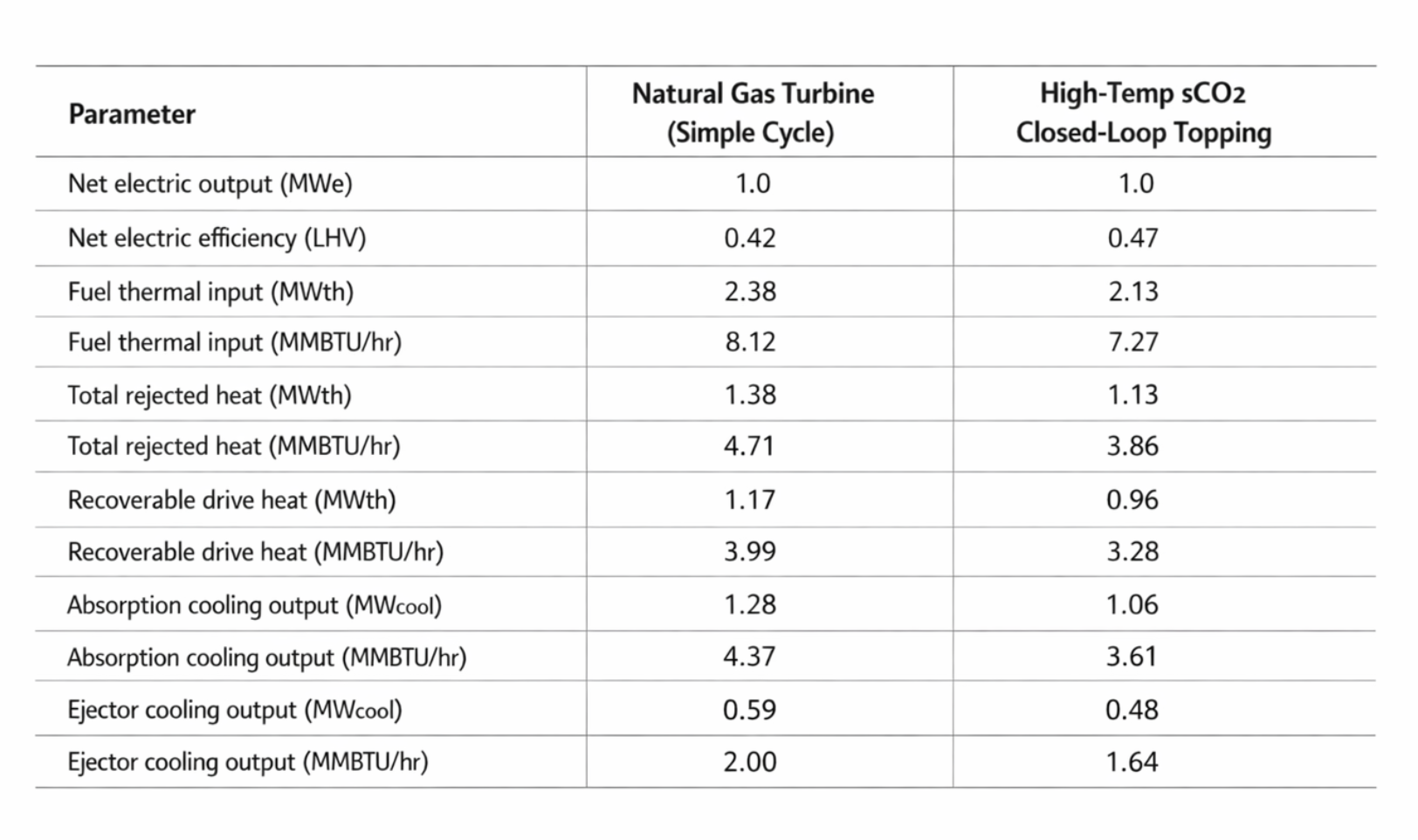

Thermodynamic Comparison Table

Below is a side-by-side thermodynamic comparison table for a 1.0 MWe module, contrasting a conventional natural gas simple-cycle turbine versus a high-temperature sCO₂ closed-loop topping cycle (natural-gas-heated), with the bottoming function focused on cooling.Key basis and assumptions (so the table is internally consistent)Net electric output basis: 1.0 MWeFuel basis: Natural gas LHVAmbient for cooling: 70°F (21°C) dry coolerGas turbine net electrical efficiency (simple cycle, data-center prime power class): 42%sCO₂ net electrical efficiency (high-temp recuperated, 700–750°C TIT class): 47%Recoverable “drive heat” fraction of rejected heat for cooling: 85% (non-condensing stack design)Cooling COP (thermal):Absorption (double-effect class): 1.1Ejector: 0.5Conversion: 1 kW = 3,412 BTU/hr, 1 MW = 3.412 MMBTU/hrThermodynamic comparison (per 1.0 MWe net)| Parameter | Natural Gas Turbine (Simple Cycle) | High-Temp sCO₂ Closed-Loop Topping (NG-Heated) || -• | -: | -: || Net electric output | 1.00 MWe | 1.00 MWe || Net electric efficiency (LHV) | 0.42 | 0.47 || Fuel thermal input | 2.38 MWth (8.12 MMBTU/hr) | 2.13 MWth (7.27 MMBTU/hr) || Total rejected heat (fuel – electric) | 1.38 MWth (4.71 MMBTU/hr) | 1.13 MWth (3.86 MMBTU/hr) || Recoverable drive heat for cooling (85% of rejected) | 1.17 MWth (3.99 MMBTU/hr) | 0.96 MWth (3.28 MMBTU/hr) || Typical exhaust / waste-heat temperature quality | High exhaust mass flow, ~450–600°C typical | Concentrated exchanger-based recovery; stack can be designed ~150–200°C || Cooling potential via absorption (COP_th=1.1) | 1.28 MWcool (4.37 MMBTU/hr) | 1.06 MWcool (3.61 MMBTU/hr) || Cooling potential via ejector (COP_th=0.5) | 0.59 MWcool (2.00 MMBTU/hr) | 0.48 MWcool (1.64 MMBTU/hr) || Overall useful energy (electric + absorption cooling) | 2.28 “useful MW” equivalent | 2.06 “useful MW” equivalent || Primary constraint / penalty | Ambient derate, intake/exhaust noise, dirty-air sensitivity | High-temp HX and materials, high-pressure CO₂ hardware |“Useful MW equivalent” here is simply MWe + MWcool (not an exergy metric). It’s a practical data-center utility metric.Interpretation (what the table implies)1. Fuel consumption: sCO₂ at 47% net uses ~10–12% less fuel per delivered MWe than a 42% simple-cycle gas turbine (7.27 vs 8.12 MMBTU/hr).2. Cooling from waste heat: the gas turbine rejects more total heat (because it’s less efficient), so it can show more absolute cooling potential if you fully harvest waste heat.However, this “advantage” comes from lower electrical efficiency—you are buying extra cooling with extra fuel.3. Best-in-class value proposition for sCO₂: the strongest case is when you value:silent operation (no large air path),no ambient derate / altitude penalty,immunity to dirty air (no compressor fouling),water-free siting (dry cooling),and a modular, sealed architecture.Optional: “Apples-to-apples cooling” normalizationIf you want the same cooling output as the gas turbine provides (e.g., 1.28 MWcool via absorption), the sCO₂ system can achieve it by:allocating more recoverable heat to the cooling generator (designing for a slightly higher stack or different recovery split), ormodestly increasing module firing rate, while still retaining the operational benefits of the sealed cycle.