INFINITY TURBINE | SALES | DESIGN | DEVELOPMENT | ANALYSIS CONSULTING

TEL: +1-608-238-6001 (Chicago Time Zone ) Email: greg@infinityturbine.com

GE Vernova Alternative: Supercritical CO2 Turbine Generator Multiple Modular Power Block MMPB Generators for Data Centers More Info

IT1000 Supercritical CO2 Gas Turbine Generator Silent Prime Power 1 MW (natural gas, solar thermal, thermal battery heat) ... More Info

New Concrete Battery Using saltwater flow battery technology...

ORC and Products Index Infinity Turbine ORC Index... More Info

|

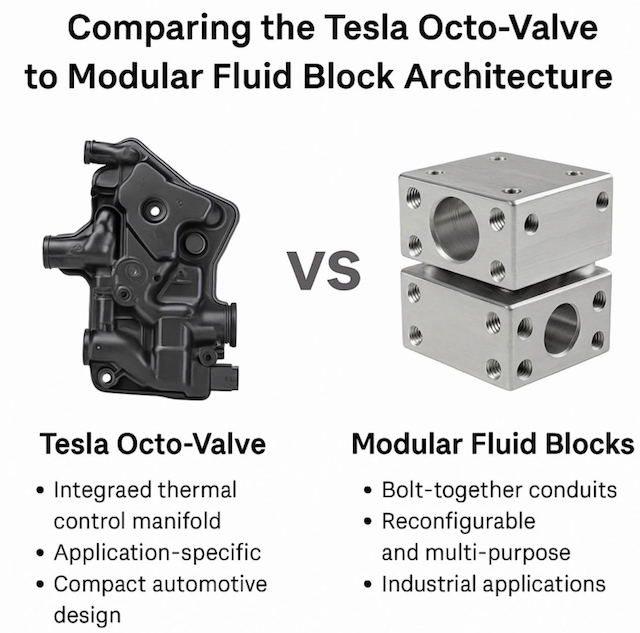

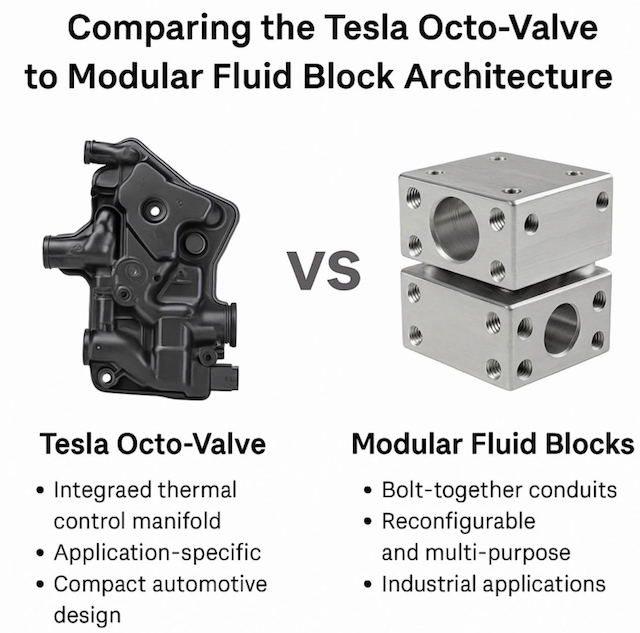

Modular Fluid Blocks vs Traditional Piping: A Smarter Path From Prototype to Commercial Systems 1. IntroductionFluid systems—whether they carry water, refrigerants, CO₂, solvents, or electrolytes—are usually built with one familiar method: piping. But as systems become more compact, more integrated, and more modular, traditional pipework often becomes chaotic. Routing, rework, leak points, and tangled geometry make prototyping slow and scaling awkward.Infinity Turbine introduced a different solution: modular fluid-conduit blocks, each with integrated channels, bores, and mounting faces that bolt together like industrial Lego. This article compares the two approaches—traditional piping vs modular blocks—across prototyping, pilot-scale development, and commercial productization.2. Traditional piping systemsTraditional piping uses straight runs of pipe connected with elbows, tees, flanges, and valves. It is the standard in industrial plants, power systems, and mechanical engineering.AdvantagesProven and standardized: Code-compliant materials and fittings exist for every pressure, temperature, and chemical requirement.Flexible routing: Pipes can be bent or arranged along complex paths.Highly scalable: Commercial systems easily scale to large diameters and high flow rates.Widely supported: Fabricators, welders, and maintenance staff understand pipe systems.DisadvantagesClutter and disorganization: Pipe racks quickly become visually confusing.Slow iterations: Changing designs requires cutting, welding, or re-routing.Higher rework cost: Even small design changes cause delays.Maintenance complexity: Multiple joints and hidden sections add leak points and inspection difficulty.For fixed industrial installations, piping excels. But for development work and evolving designs, it introduces friction.3. Modular bolt-together fluid-conduit blocksInfinity Turbine’s modular blocks are machined components with internal fluid channels that assemble into 3D fluid networks using bolts, gaskets, and standardized interfaces. These blocks function like clean, compact fluid manifolds.AdvantagesFast prototyping: Blocks assemble, reconfigure, and disassemble rapidly.Clean layout: Channels are inside blocks—no tangled pipe jungle.Integrated functions: Blocks can include ports for pumps, turbomachinery, mixers, or heat exchangers.Repeatability: Once a working configuration is found, it can be duplicated as a module.Modular scaling: Adding capacity is as simple as adding more blocks or parallel assemblies.DisadvantagesPressure/material limits: Blocks must be designed to withstand target pressure and temperature.Cost at very large scale: Extremely high flow rates may favor traditional piping.More joints per volume: Each block interface needs sealing and torque control.Non-standard hydraulics: Flow dynamics may need tuning since channels are not traditional pipe geometries.For rapid design cycles and compact systems, modular blocks are extremely effective.4. Prototype, pilot, and commercial transitionsPrototype stageModular blocks shine here:Fast layout changesVisual clarityEasy integration of instrumentationLower rework costCleaner “experimental geometry”Piping is still usable, but slow to modify and hard to keep organized.Pilot stageA hybrid approach works well:Blocks for manifolds, internal routing, testing modulesPipes for external utilities, large diameter inputs/outputsBlocks simplify documentation and replication of the pilot system.Commercial stageBoth approaches can be used depending on the product:Modular blocks suit compact, containerized, or skid-based systems.Traditional piping suits very large flow or industrial-scale plants.Often the winning strategy is a mixed architecture: block-based functional modules with traditional pipes for long or high-volume runs.5. ConclusionPiping will always dominate full-scale industrial systems, but as development cycles accelerate and modular manufacturing expands, Infinity Turbine’s block-based approach offers enormous advantages. From rapid prototyping to clean system layouts to modular commercial products, fluid-conduit blocks provide a flexible, repeatable, and elegant path forward.For engineers and companies developing turbines, heat pumps, ORC systems, CO₂ loops, flow batteries, and advanced reactors, modular block systems reduce clutter, shorten development time, and simplify scaling—turning fluid handling into a modern, modular platform instead of a maze of pipes. |

|

| CONTACT TEL: +1-608-238-6001 (Chicago Time Zone USA) Email: greg@infinityturbine.com | AMP | PDF |