Cost Comparison of Hybrid Cavitation–Supercritical CO2 Nanoparticle Production Versus Traditional Methods

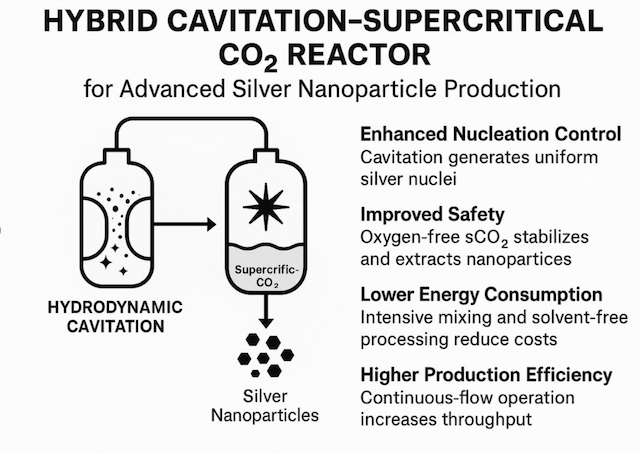

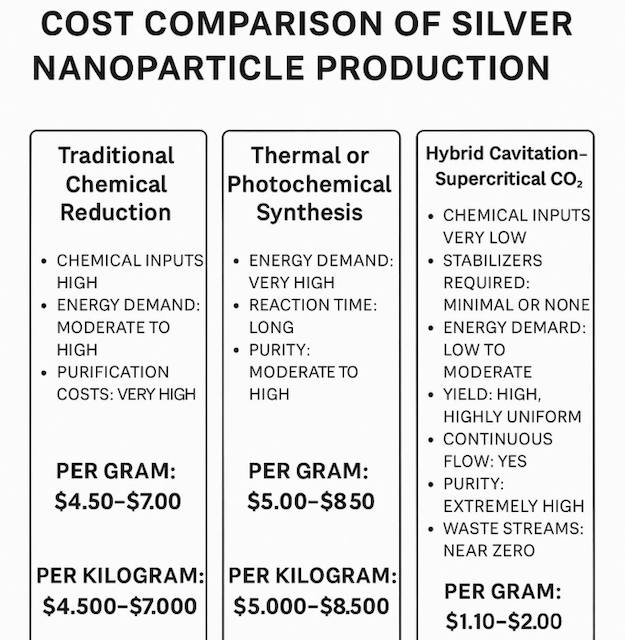

Cost Comparison of Hybrid Cavitation–Supercritical CO2 Nanoparticle Production Versus Traditional MethodsSilver nanoparticles command high prices in global markets due to their antimicrobial, catalytic, optical, and electronic applications. However, conventional production methods rely on large chemical inventories, stabilizers, reductants, energy-intensive reactors, and complex purification steps. These factors keep costs high and limit scalability. A hybrid hydrodynamic cavitation–supercritical CO2 (sCO2) production system addresses these issues through intensified mixing, continuous-flow processing, and solvent-free extraction.Traditional chemical synthesis typically operates in batch mode using silver nitrate, sodium borohydride, citrate, polymers, and stabilizers, followed by centrifugation and washing. Energy consumption, hazardous chemicals, and waste stream treatment significantly increase per-gram cost. Thermal reduction and photochemical methods also demand specialized equipment and long reaction times, translating to high operating expenses.By contrast, a hybrid cavitation–sCO2 reactor achieves nucleation under intense micro-mixing conditions generated by collapsing cavitation bubbles. The resulting uniform nuclei move directly into a supercritical CO2 phase where controlled growth and solvent-free extraction occur. This eliminates most stabilizers, reduces chemical consumption, and allows continuous production with minimal labor.Below is the cost comparison.Cost Comparison (Per Gram and Per Kilogram)These values represent typical market and production cost ranges for high-purity silver nanoparticles (20 to 80 nm range).1. Traditional Chemical ReductionChemical Inputs: HighEnergy Demand: Moderate to highPurification Costs: Very highBatch Labor Costs: HighEstimated Production Cost:Per gram: 4.50 to 7.00 USDPer kilogram: 4,500 to 7,000 USDMarket Price: Often 10 to 45 USD per gram depending on grade2. Thermal or Photochemical SynthesisEnergy Demand: Very highReaction Time: LongPurity: Moderate to highEstimated Production Cost:Per gram: 5.00 to 8.50 USDPer kilogram: 5,000 to 8,500 USD3. Hybrid Cavitation–Supercritical CO2 (New System)Chemical Inputs: Very lowStabilizers Required: Minimal or noneEnergy Demand: Low to moderateYield: High, highly uniformContinuous Flow: YesPurity: Extremely highWaste Streams: Near zeroEstimated Production Cost:Per gram: 1.10 to 2.00 USDPer kilogram: 1,100 to 2,000 USDWhy the Hybrid System Costs LessReduced ChemicalsCavitation provides natural fragmentation and nucleation, while sCO2 handles extraction without surfactants or solvents.Continuous ManufacturingContinuous operation reduces downtime, labor, and batch-cycle inefficiencies.Lower Energy UseCavitation uses mechanical energy instead of thermal energy, and sCO2 processing uses moderate pressures and temperatures with efficient recovery loops.Higher Yield and UniformityLess waste, fewer rejected batches, and more consistent particle size distribution reduce overall cost.Cleaner ProcessingsCO2 eliminates purification steps, reducing labor and eliminating expensive centrifugation or filtration.ConclusionProducing silver nanoparticles using a hybrid cavitation–supercritical CO2 system cuts costs by 60 to 75 percent compared to conventional batch chemical or thermal synthesis. The technology improves purity, reduces environmental impact, and provides a scalable pathway for high-value nanoparticle manufacturing.