|

|

|

electrostatic collection using the infinity supercritical co2 extraction

|

Processing Advantages

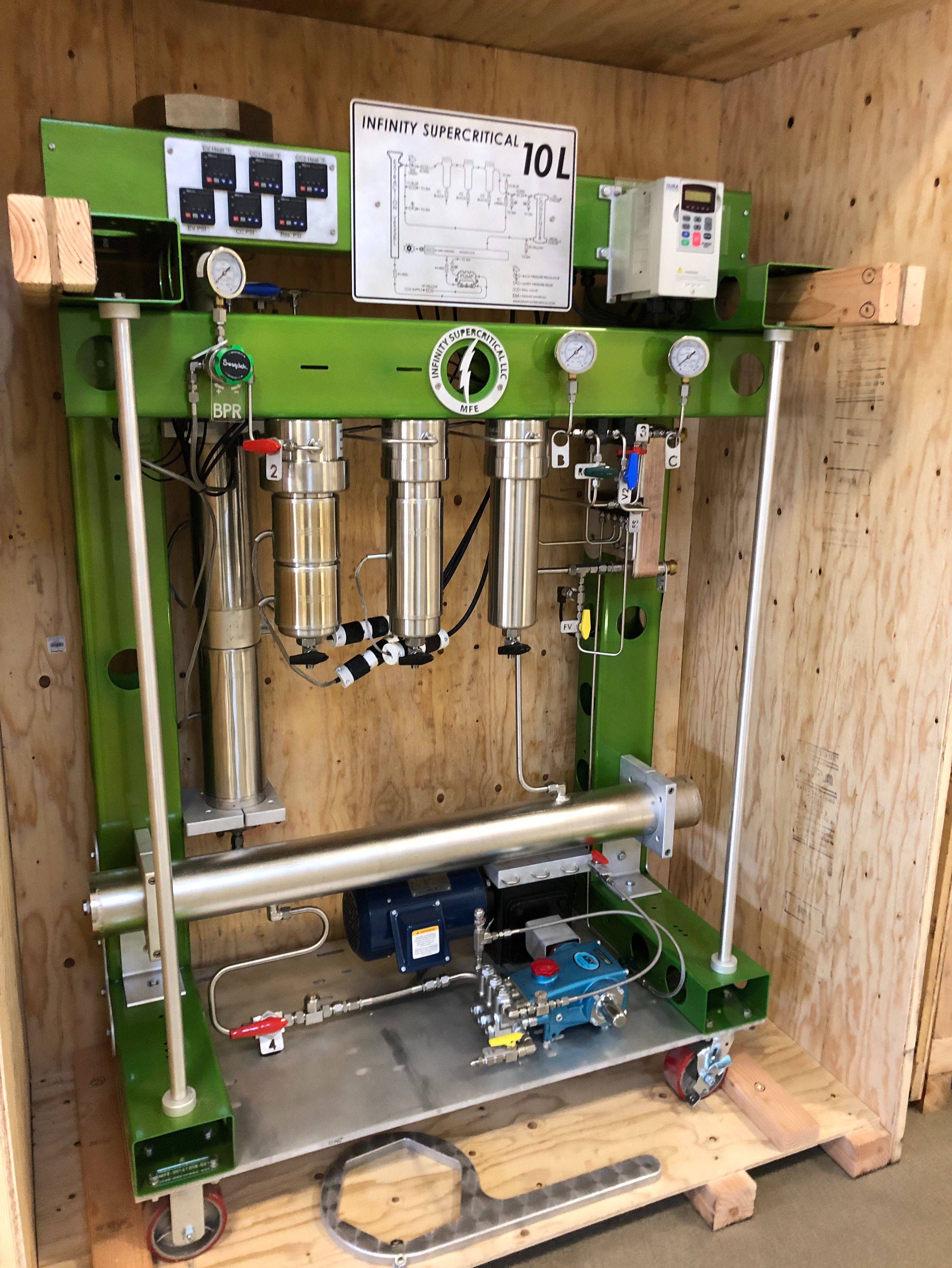

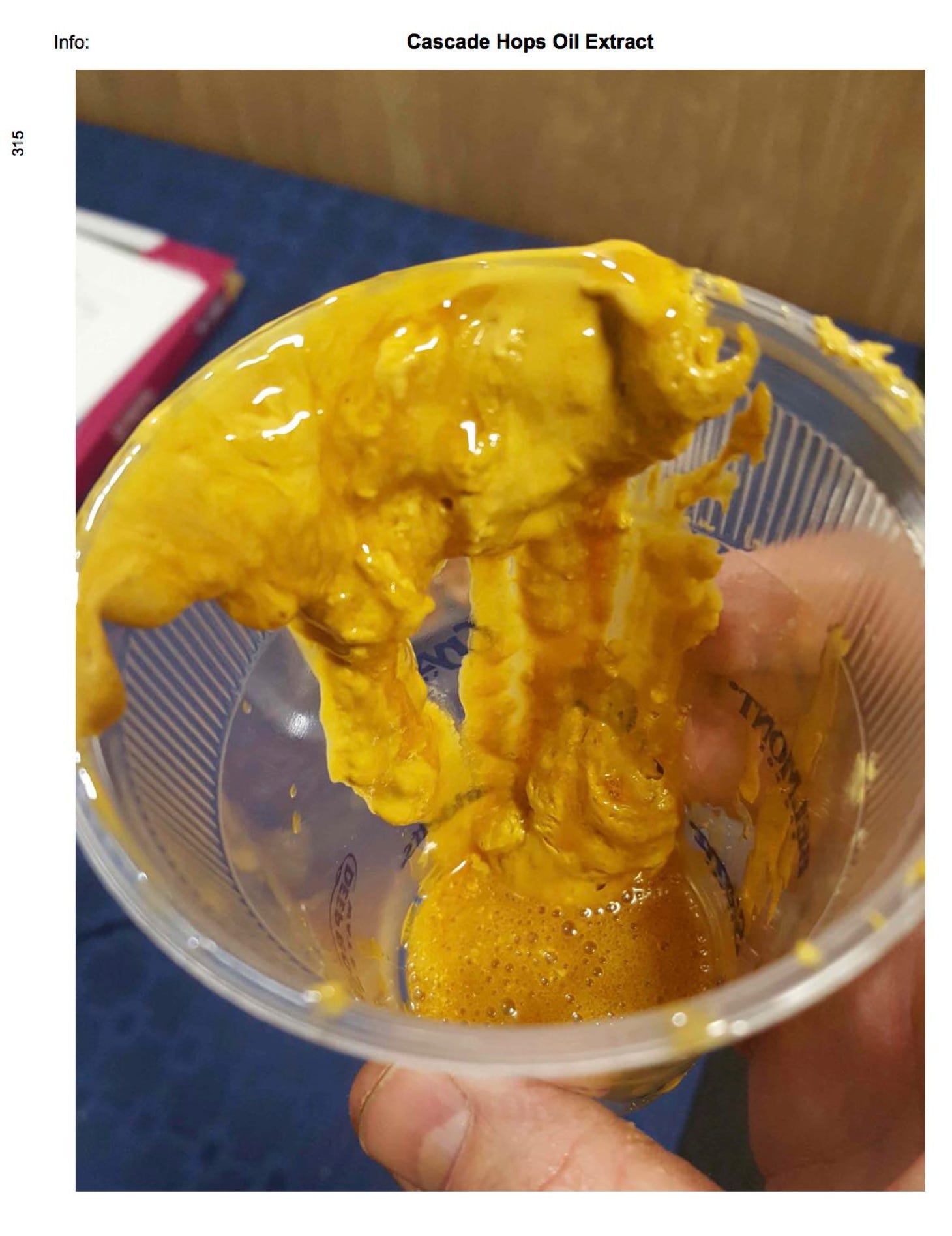

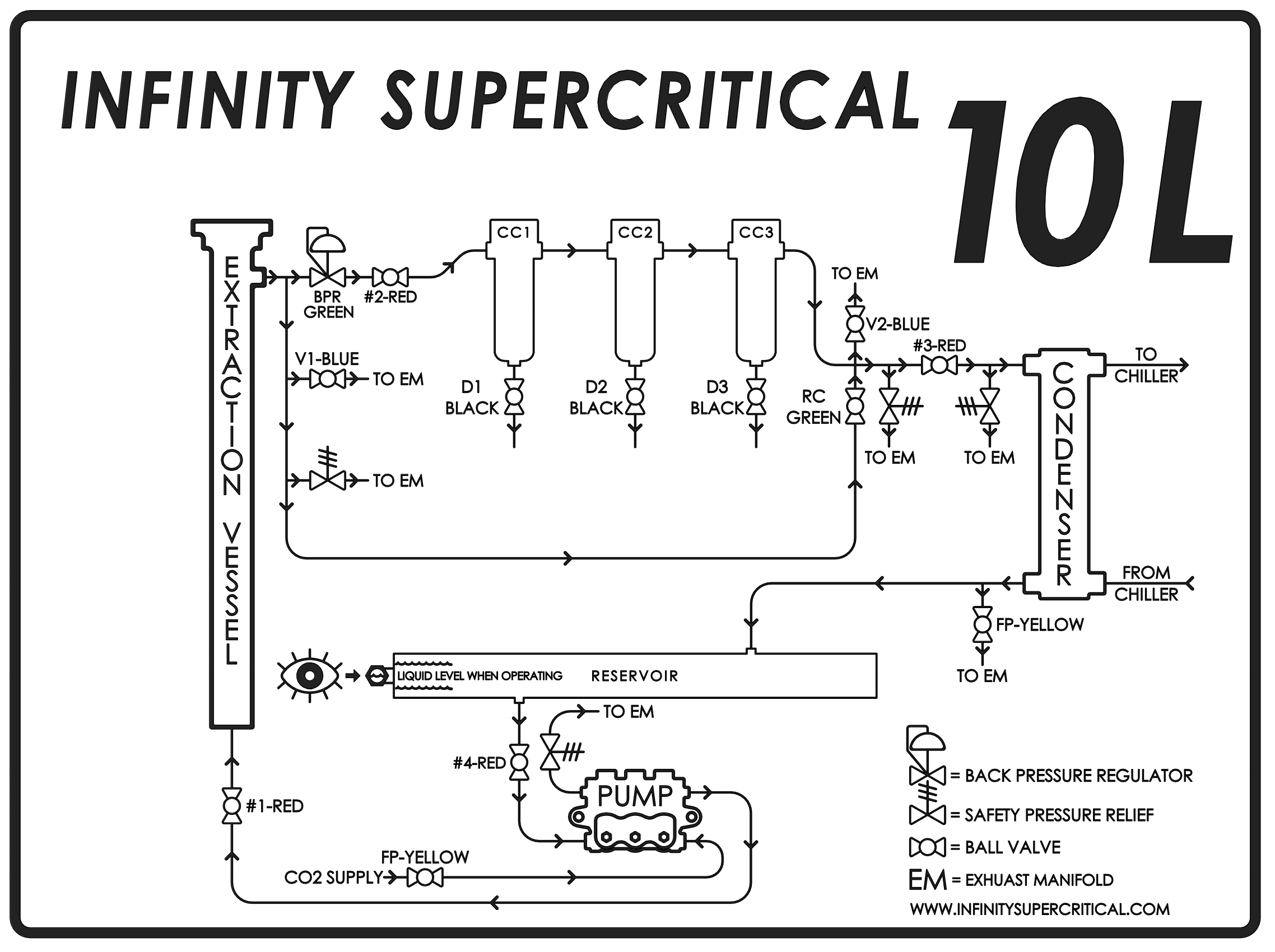

Low Carry-Over (More Extracted Oil You Can Sell): Reducing carry-over saves time and parts costs in system maintenance, and puts more profit into your pocket. It also means less time spent on upkeep with the machine, and more time spent on extracting oil.Target Oil and Reduce Post Processing Time (Save more than 50 percent of your time by targeting oil you want, not wax): Systems are designed to target oil production at pressures lower than 2,000 psi, which specifically can retain valuable terpenes, and emphasize oil harvesting, instead of waxes and other byproducts, which need to be removed in post processing. The crude oil output from the 10L is considered a full spectrum oil, and can be sold directly as-is, or mixed with a carrier oil (such as coconut oil) and bottled for sale.Run 2 Months Without Pump Cleaning (expert status operator with training and experience): Quiet, reliable, and lowest maintenance CO2 pump in the industry. We have one customer who has run his machine almost everyday for 2 months without cleaning his CO2 pump. We also are the first company to provide a bolt-on pump cleaner to clean your pump head in-place. We specialize in collecting the oil before it gets to the CO2 pump using our proprietary electrostatic collector. Others make you buy additional pumps, or require cleaning every few days.Cleaning: Respect your equipment, and it will operate great. We recently had one customer comment that the 10L was a gold mine and was looking forward to his second machine, to make even more profit. Keeping a system clean so that it operates correctly is true with most equipment. We recommend always keeping your machine clean, and at least every 15 cycles do a thorough ethanol clean out of the system. If you do not clean your machine, expect that it will not work at all. We’ve had customers that don’t clean their machine at all, and they go through seals on a weekly basis, then wonder why it isn’t operating up to expectations. We’ve had a few groups return machines for repair, and all that was needed was a good machine cleaning. Have some respect for your profit center, and you’ll get great results.System Components: 3 collection vessels with bottom exit valves, heat recovery system, CO2 preheat, electrostatic collection, FlowBar, spares package, shipping, crate, chiller, extra baskets, bolt on pump cleaner, training, support, pump head cleaning holder, vent tube and manifold, CO2 monitor, CO2 liquid sight-glass.

|