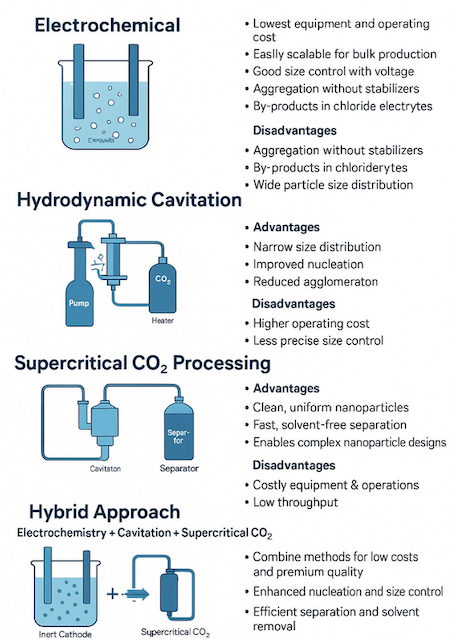

Comparing Electrochemical, Cavitation, and Supercritical CO₂ Methods for Silver Nanoparticle Production: A Cost-Effective Hybrid Approach

Silver nanoparticles are essential for modern technologies ranging from electronics and advanced coatings to medical materials, antimicrobial films, catalysts, and ferrofluids. With demand rising and values often exceeding forty dollars per gram, selecting the right production method determines both profitability and material performance. Three major processes dominate the field today: electrochemical synthesis, hydrodynamic cavitation, and supercritical CO₂ processing. Each method offers unique advantages in cost, purity, production volume, and precision. By comparing their strengths and limitations, it becomes possible to engineer a hybrid approach that maximizes output quality while minimizing cost.Electrochemical synthesis is the most economical method for producing silver nanoparticles. It requires only a silver anode, an inert cathode such as titanium, a simple electrolyte, and a direct-current power supply. The operating costs are extremely low because the process uses minimal electricity and low-cost materials. Production can be scaled by increasing electrode surface area or by deploying multi-cell continuous flow systems. This method excels when large volumes of low• to medium-grade nanoparticles are required. However, it struggles with tight size distribution, can produce unwanted silver chloride if saltwater is used, and often requires stabilizing chemicals to prevent aggregation. Despite these limitations, it remains the lowest-cost entry point for commercial production.Hydrodynamic cavitation is a more advanced technique that uses collapsing microbubbles and intense shear forces to drive rapid nucleation and controlled nanoparticle formation. Cavitation produces better uniformity and smaller particle sizes compared to pure electrochemical synthesis. When combined with high shear from spinning disc reactors, mixing becomes extremely fast and uniform, leading to narrower size distributions and improved control over particle formation. Cavitation alone is more expensive to operate than electrochemistry due to pump requirements and flow-rate demands, but it substantially improves particle quality.Supercritical CO₂ processing provides the highest precision, cleanest separation, and best control over nanoparticle morphology. Under supercritical conditions, CO₂ acts as a powerful solvent with very low surface tension, enabling uniform nucleation, instant solvent removal, and prevention of agglomeration. This method excels when purity is critical, such as in electronic, medical, or coated nanoparticles. It also enables advanced designs including coated particles, core–shell structures, and ferrofluid-compatible materials. However, the equipment and operating costs are significantly higher, making it less suitable for bulk, low-cost nanoparticle production without an optimization strategy.The most cost-effective approach is a hybrid solution combining all three methods. Electrochemistry provides the lowest-cost source of silver ions and initial nanoparticle formation. Hydrodynamic cavitation improves nucleation control and enhances uniformity. Supercritical CO₂ processing finishes the material with rapid solvent extraction, uniform drying, and perfect separation without contaminants. This blend delivers the best performance-to-cost ratio: extremely pure, highly uniform nanoparticles at a production cost far lower than a full supercritical CO₂ system alone. By integrating electrochemical silver generation, cavitation mixing, and supercritical CO₂ finishing, a scalable and profitable pathway emerges for producing commercial-grade nanoparticles with premium characteristics and strong market value.