PDF Publication Title:

Text from PDF Page: 002

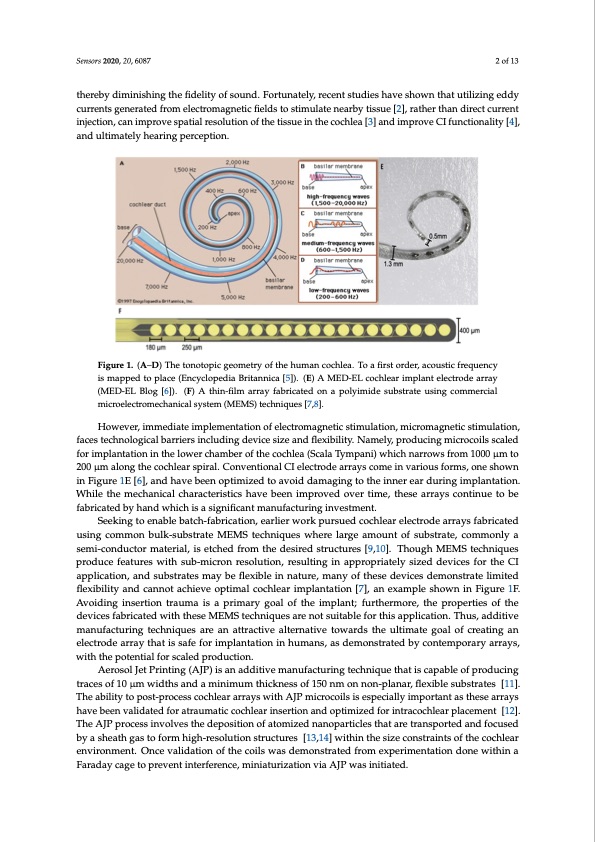

Sensors 2020, 20, 6087 2 of 13 thereby diminishing the fidelity of sound. Fortunately, recent studies have shown that utilizing eddy currents generated from electromagnetic fields to stimulate nearby tissue [2], rather than direct current injection, can improve spatial resolution of the tissue in the cochlea [3] and improve CI functionality [4], and ultimately hearing perception. Figure 1. (A–D) The tonotopic geometry of the human cochlea. To a first order, acoustic frequency is mapped to place (Encyclopedia Britannica [5]). (E) A MED-EL cochlear implant electrode array (MED-EL Blog [6]). (F) A thin-film array fabricated on a polyimide substrate using commercial microelectromechanical system (MEMS) techniques [7,8]. However, immediate implementation of electromagnetic stimulation, micromagnetic stimulation, faces technological barriers including device size and flexibility. Namely, producing microcoils scaled for implantation in the lower chamber of the cochlea (Scala Tympani) which narrows from 1000 μm to 200 μm along the cochlear spiral. Conventional CI electrode arrays come in various forms, one shown in Figure 1E [6], and have been optimized to avoid damaging to the inner ear during implantation. While the mechanical characteristics have been improved over time, these arrays continue to be fabricated by hand which is a significant manufacturing investment. Seeking to enable batch-fabrication, earlier work pursued cochlear electrode arrays fabricated using common bulk-substrate MEMS techniques where large amount of substrate, commonly a semi-conductor material, is etched from the desired structures [9,10]. Though MEMS techniques produce features with sub-micron resolution, resulting in appropriately sized devices for the CI application, and substrates may be flexible in nature, many of these devices demonstrate limited flexibility and cannot achieve optimal cochlear implantation [7], an example shown in Figure 1F. Avoiding insertion trauma is a primary goal of the implant; furthermore, the properties of the devices fabricated with these MEMS techniques are not suitable for this application. Thus, additive manufacturing techniques are an attractive alternative towards the ultimate goal of creating an electrode array that is safe for implantation in humans, as demonstrated by contemporary arrays, with the potential for scaled production. Aerosol Jet Printing (AJP) is an additive manufacturing technique that is capable of producing traces of 10 μm widths and a minimum thickness of 150 nm on non-planar, flexible substrates [11]. The ability to post-process cochlear arrays with AJP microcoils is especially important as these arrays have been validated for atraumatic cochlear insertion and optimized for intracochlear placement [12]. The AJP process involves the deposition of atomized nanoparticles that are transported and focused by a sheath gas to form high-resolution structures [13,14] within the size constraints of the cochlear environment. Once validation of the coils was demonstrated from experimentation done within a Faraday cage to prevent interference, miniaturization via AJP was initiated.PDF Image | Silver-Nanoparticle Microcoil via Aerosol Jet Printing

PDF Search Title:

Silver-Nanoparticle Microcoil via Aerosol Jet PrintingOriginal File Name Searched:

sensors-20-06087-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |