PDF Publication Title:

Text from PDF Page: 003

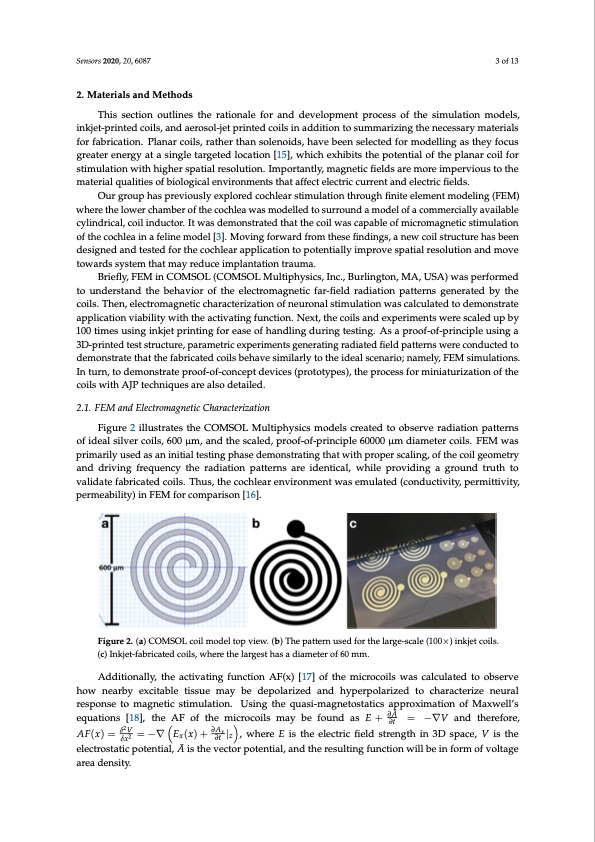

Sensors 2020, 20, 6087 3 of 13 2. Materials and Methods This section outlines the rationale for and development process of the simulation models, inkjet-printed coils, and aerosol-jet printed coils in addition to summarizing the necessary materials for fabrication. Planar coils, rather than solenoids, have been selected for modelling as they focus greater energy at a single targeted location [15], which exhibits the potential of the planar coil for stimulation with higher spatial resolution. Importantly, magnetic fields are more impervious to the material qualities of biological environments that affect electric current and electric fields. Our group has previously explored cochlear stimulation through finite element modeling (FEM) where the lower chamber of the cochlea was modelled to surround a model of a commercially available cylindrical, coil inductor. It was demonstrated that the coil was capable of micromagnetic stimulation of the cochlea in a feline model [3]. Moving forward from these findings, a new coil structure has been designed and tested for the cochlear application to potentially improve spatial resolution and move towards system that may reduce implantation trauma. Briefly, FEM in COMSOL (COMSOL Multiphysics, Inc., Burlington, MA, USA) was performed to understand the behavior of the electromagnetic far-field radiation patterns generated by the coils. Then, electromagnetic characterization of neuronal stimulation was calculated to demonstrate application viability with the activating function. Next, the coils and experiments were scaled up by 100 times using inkjet printing for ease of handling during testing. As a proof-of-principle using a 3D-printed test structure, parametric experiments generating radiated field patterns were conducted to demonstrate that the fabricated coils behave similarly to the ideal scenario; namely, FEM simulations. In turn, to demonstrate proof-of-concept devices (prototypes), the process for miniaturization of the coils with AJP techniques are also detailed. 2.1. FEM and Electromagnetic Characterization Figure 2 illustrates the COMSOL Multiphysics models created to observe radiation patterns of ideal silver coils, 600 μm, and the scaled, proof-of-principle 60000 μm diameter coils. FEM was primarily used as an initial testing phase demonstrating that with proper scaling, of the coil geometry and driving frequency the radiation patterns are identical, while providing a ground truth to validate fabricated coils. Thus, the cochlear environment was emulated (conductivity, permittivity, permeability) in FEM for comparison [16]. Figure 2. (a) COMSOL coil model top view. (b) The pattern used for the large-scale (100×) inkjet coils. (c) Inkjet-fabricated coils, where the largest has a diameter of 60 mm. Additionally, the activating function AF(x) [17] of the microcoils was calculated to observe how nearby excitable tissue may be depolarized and hyperpolarized to characterize neural response to magnetic stimulation. Using the quasi-magnetostatics approximation of Maxwell’s equations [18], the AF of the microcoils may be found as E + ∂A ̄ = −∇V and therefore, ∂t AF(x) = δ2V = −∇ E (x) + ∂Ax | , where E is the electric field strength in 3D space, V is the δx2 x ∂t z electrostatic potential, A ̄ is the vector potential, and the resulting function will be in form of voltage area density.PDF Image | Silver-Nanoparticle Microcoil via Aerosol Jet Printing

PDF Search Title:

Silver-Nanoparticle Microcoil via Aerosol Jet PrintingOriginal File Name Searched:

sensors-20-06087-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |