PDF Publication Title:

Text from PDF Page: 002

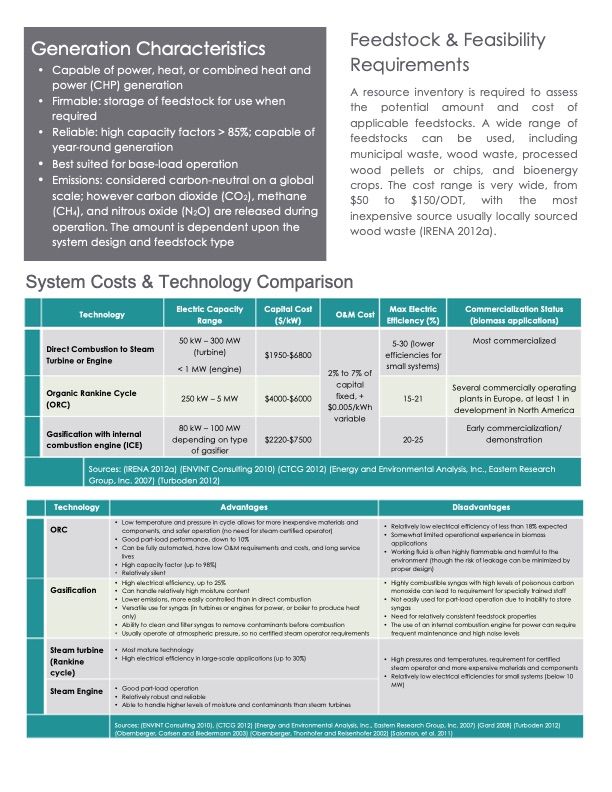

Generation Characteristics • Capable of power, heat, or combined heat and power (CHP) generation • Firmable: storage of feedstock for use when required • Reliable: high capacity factors > 85%; capable of year-round generation • Best suited for base-load operation • Emissions: considered carbon-neutral on a global scale; however carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) are released during operation. The amount is dependent upon the system design and feedstock type Feedstock & Feasibility Requirements A resource inventory is required to assess the potential amount and cost of applicable feedstocks. A wide range of feedstocks can be used, including municipal waste, wood waste, processed wood pellets or chips, and bioenergy crops. The cost range is very wide, from $50 to $150/ODT, with the most inexpensive source usually locally sourced wood waste (IRENA 2012a). System Costs & Technology Comparison Technology Direct Combustion to Steam Turbine or Engine Organic Rankine Cycle (ORC) Gasification with internal combustion engine (ICE) Electric Capacity Range 50 kW – 300 MW (turbine) < 1 MW (engine) 250 kW – 5 MW 80 kW – 100 MW depending on type of gasifier Capital Cost ($/kW) $1950-$6800 $4000-$6000 $2220-$7500 O&M Cost 2% to 7% of capital fixed, + $0.005/kWh variable Max Electric Efficiency (%) 5-30 (lower efficiencies for small systems) 15-21 20-25 Commercialization Status (biomass applications) Most commercialized Several commercially operating plants in Europe, at least 1 in development in North America Early commercialization/ demonstration Sources: (IRENA 2012a) (ENVINT Consulting 2010) (CTCG 2012) (Energy and Environmental Analysis, Inc., Eastern Research Group, Inc. 2007) (Turboden 2012) Technology ORC Gasification Steam turbine (Rankine cycle) Steam Engine Advantages • Low temperature and pressure in cycle allows for more inexpensive materials and components, and safer operation (no need for steam certified operator) • Good part-load performance, down to 10% • Can be fully automated, have low O&M requirements and costs, and long service lives • High capacity factor (up to 98%) • Relatively silent • High electrical efficiency, up to 25% • Can handle relatively high moisture content • Lower emissions, more easily controlled than in direct combustion • Versatile use for syngas (in turbines or engines for power, or boiler to produce heat only) • Ability to clean and filter syngas to remove contaminants before combustion • Usually operate at atmospheric pressure, so no certified steam operator requirements • Most mature technology • High electrical efficiency in large-scale applications (up to 30%) • Good part-load operation • Relatively robust and reliable • Able to handle higher levels of moisture and contaminants than steam turbines Disadvantages • Relatively low electrical efficiency of less than 18% expected • Somewhat limited operational experience in biomass applications • Working fluid is often highly flammable and harmful to the environment (though the risk of leakage can be minimized by proper design) • Highly combustible syngas with high levels of poisonous carbon monoxide can lead to requirement for specially trained staff • Not easily used for part-load operation due to inability to store syngas • Need for relatively consistent feedstock properties • The use of an internal combustion engine for power can require frequent maintenance and high noise levels • High pressures and temperatures, requirement for certified steam operator and more expensive materials and components • Relatively low electrical efficiencies for small systems (below 10 MW) Sources: (ENVINT Consulting 2010), (CTCG 2012) (Energy and Environmental Analysis, Inc., Eastern Research Group, Inc. 2007) (Gard 2008) (Turboden 2012) (Obernberger, Carlsen and Biedermann 2003) (Obernberger, Thonhofer and Reisenhofer 2002) (Salomon, et al. 2011)PDF Image | Biomass Conversion Technologies

PDF Search Title:

Biomass Conversion TechnologiesOriginal File Name Searched:

Summary_Guide_to_Technologies_Considered.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |