PDF Publication Title:

Text from PDF Page: 003

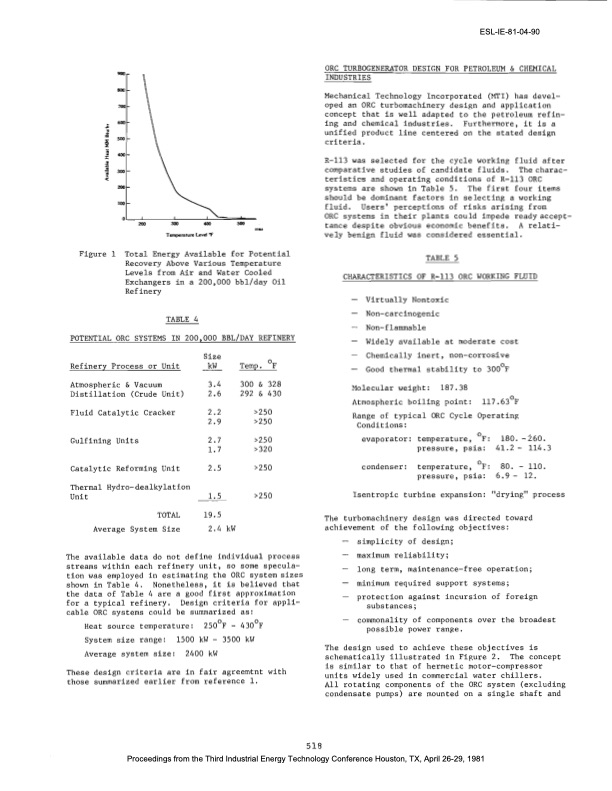

900 800 700 600 ~ ORC TURBOGENERATOR DESIGN FOR PETROLEUM & CHEMICAL INDUSTRIES Mechanical Technology Incorporated (MTI) has devel oped an ORC turbomachinery design and application concept that is well adapted to the petroleum refin ing and chemical industries. Furthermore, it is a unified product line centered on the stated design criteria. R-113 was selected for the cycle working fluid after comparative studies of candidate fluids. Thecharac teristics and operating conditions of R-113 ORC systems are shown in Table 5. The first four items should be dominant factors in selecting a working fluid. Users' perceptions of risks arising from ORC systems in their plants could impede ready accept tance despite obvious economic benefits. A relati vely benign fluid was considered essential. TABLE 5 CHARACTERISTICS OF R-113 ORC WORKING FLUID Virtually Nontoxic Non-carcinogenic Non-flammable Widely available at moderate cost Chemically inert, non-corrosive eli 500 ~ i " lj 300 200 100 Refinery Process or Unit Atmospheric & Vacuum Distillation (Crude Unit) Fluid Catalytic Cracker Gulfining Units Catalytic Reforming Unit Size kW 3.4 2.6 2.2 2.9 2.7 1.7 2.5 Temp. of 300 & 328 292 & 430 >250 >250 >250 >320 >250 >250 0 Good thermal stability to 300 F ~10lecular w e i g h t : 1 8 7 . 3 8 0 Atmospheric boiling point: l17.63 F Range of typical ORC Cycle Operating Conditions: evaporator: temperature, of: 180. - 260. pressure, psia: 41.2 - 114.3 condenser: temperature, of: 80. - 110. pressure, psia: 6.9 - 12. Isentropic turbine expansion: "drying" process The turbomachinery design was directed toward achievement of the following objectives: simplicity of design; maximum reliability; long term, maintenance-free operation; minimum required support systems; protection against incursion of foreign substances; commonality of components over the broadest possible power range. The design used to achieve these objectives is schematically illustrated in Figure 2. The concept is similar to that of hermetic motor-compressor units widely used in commercial water chillers. All rotating components of the ORC system (excluding condensate pumps) are mounted on a single shaft and 518 Thermal Hydro-dealkylation Unit 1.5 TOTAL 1 9 . 5 Average System Size 2.4 kW Temperature level Of Figure 1 Total Energy Available for Potential Recovery Above Various Temperature Levels from Air and Water Cooled Exchangers in a 200,000 bbl/day Oil Refinery TABLE 4 POTENTIAL ORC SYSTEMS IN 200,000 BBL/DAY REFINERY The available data do not define individual process streams within each refinery unit, so some specula tion was employed in estimating the ORC system sizes shown in Table 4. Nonetheless, it is believed that the data of Table 4 are a good first approximation for a typical refinery. Design criteria for appli cable ORC systems could be summarized as: 0 0 Heat source temperature: 250 F - 430 F System size range: 1500 kW - 3500 kW Average system size: 2400 kW These design criteria are in fair agreemtnt with those summarized earlier from reference 1. 500 Proceedings from the Third Industrial Energy Technology Conference Houston, TX, April 26-29, 1981 ESL-IE-81-04-90PDF Image | ORC WASTE HEAT RECOVERY IN REFINERIES AND CHEMICAL Process

PDF Search Title:

ORC WASTE HEAT RECOVERY IN REFINERIES AND CHEMICAL ProcessOriginal File Name Searched:

ESL_IE_81_04_90.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |