PDF Publication Title:

Text from PDF Page: 002

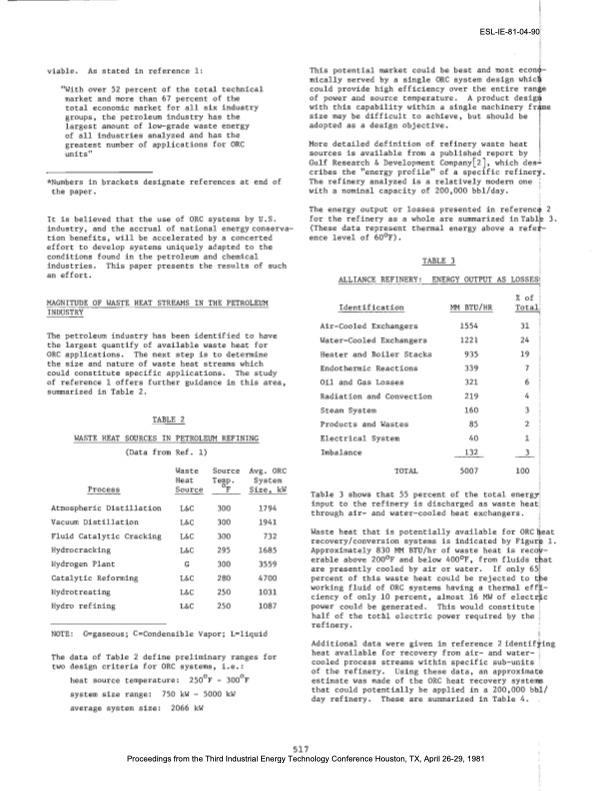

viable. As stated in reference 1: "With over 52 percent of the total technical market and more than 67 percent of the total economic market for all six industry groups, the petroleum industry has the largest amount of low-grade waste energy ,of all industries analyzed and has the greatest number of applications for aRC units" *Numbers in brackets designate references at end of the paper. It is believed that the use of aRC systems by U.S. industry, and the accrual of national energy conserva tion benefits, will be accelerated by a concerted effort to develop systems uniquely adapted to the conditions found in the petroleum and chemical industries. This paper presents the results of such an effort. MAGNITUDE OF WASTE HEAT STREAMS IN THE PETROLEUM INDUSTRY The petroleum industry has been identified to have the largest quantify of available waste heat for aRC applications. The next step is to determine the size and nature of waste heat streams which could constitute specific applications. The study of reference 1 offers further guidance in this area, summarized in Table 2. TABLE 2 WASTE HEAT SOURCES IN PETROLEUM REFINING (Data from Ref. 1) I ESL-IE-81-04-90I I I This potential market could be best and most econJ mically served by a single aRC system design whic~ could provide high efficiency over the entire range of power and source temperature. A product desig~ with this capability within a single machinery frl'me size may be difficult to achieve, but should be adopted as a design objective. More detailed definition of sources is available from a Gulf Research & Development cribes the "energy profile" The refinery analyzed is a relatively modern one ' with a nominal capacity of 200,000 bbl/day. ,i The energy output or losses presented in referenc~ 2 for the refinery as a whole are summarized inTablb 3. (These data represent thermal energy above a refet ence level of 600F). TABLE 3 ALLIANCE REFINERY: ENERGY OUTPUT AS LOSSES' Identification Air-Cooled Exchangers Water-Cooled Exchangers Heater and Boiler Stacks Endothermic Reactions Oil and Gas Losses Radiation and Convection Steam System Products and Wastes Electrical System Imbalance TOT AL MM BTU/HR 1554 1221 935 339 321 219 160 85 40 132 5 0 0 7 I %of ; I Total! 31 i 24 19 7 6 4 3 2 1 3 1 0 0 " refinery waste heat I published report by I CompanY[2J, which des~ of a specific refinery. Process Atmospheric Distillation Vacuum Distillation Fluid Catalytic Cracking Hydrocracking Hydrogen Plant Catalytic Reforming Hydrotreating Hydro refining aRC Size, kW I It \~aste Heat Source L&C L&C L&C L&C G L&C L&C L&C S o u r c e Temp. of 300 300 300 295 300 280 250 250 A v g . System NOTE: G=gaseous; C=Condensible Vapor; L=liquid The data of Table 2 define preliminary ranges for two design criteria for aRC systems, i.e.: 00 heat source temperature: 250 F - 300 F system size range: 750 kW - 5000 kW average system size: 2066 kW Waste heat that is potentially available for ORC~eat recovery/conversion systems is indicated by Figur 1. Approximately 830 MM BTU/hr of waste heat is reco erable above 2000 F and below 4000 F, from fluids t at are presently cooled by air or water. If only 65 percent of this waste heat could be rejected to t e working fluid of aRC systems having a thermal eff' ciency of only 10 percent, almost 16 MW of electr c power could be generated. This would constitute " half of the total electric power required by the refinery. ' ! Additional data were given in reference 2 identifting heat available for recovery from air- and water- I cooled process streams within specific sub-units i of the refinery. Using these data, an approximate estimate was made of the aRC heat recovery systems that could potentially be applied in a 200,000 bbl/ day refinery. These are summarized in Table 4. 517 1794 1941 732 1685 3559 4700 1031 1087 Table 3 shows that 55 percent of the total energyl input to the refinery is discharged as waste heatt Proceedings from the Third Industrial Energy Technology Conference Houston, TX, April 26-29, 1981 through air- and water-cooled heat exchangers. IPDF Image | ORC WASTE HEAT RECOVERY IN REFINERIES AND CHEMICAL Process

PDF Search Title:

ORC WASTE HEAT RECOVERY IN REFINERIES AND CHEMICAL ProcessOriginal File Name Searched:

ESL_IE_81_04_90.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |