PDF Publication Title:

Text from PDF Page: 001

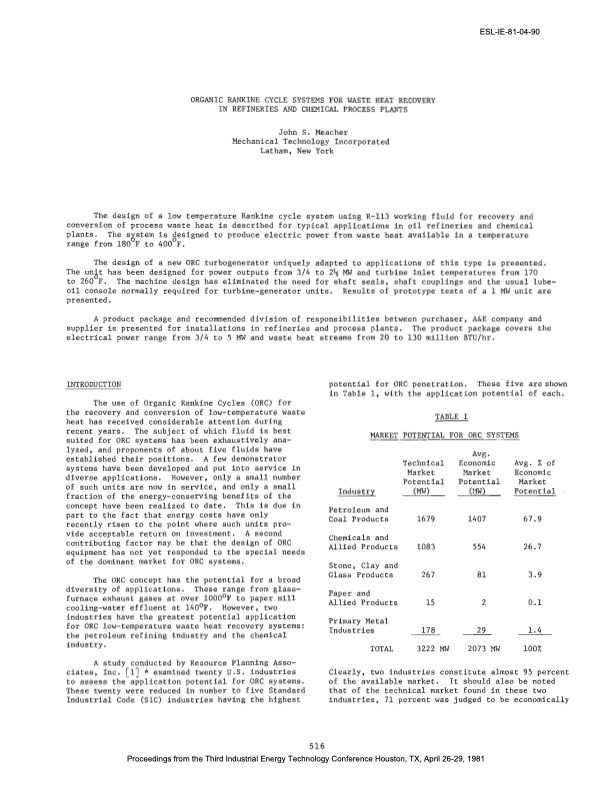

ORGANIC RANKINE CYCLE SYSTEMS FOR WASTE HEAT RECOVERY IN REFINERIES AND CHEMICAL PROCESS PLANTS John S. Meacher Mechanical Technology Incorporated Latham, New York The design of a low temperature Rankine cycle system using R-113 working fluid for recovery and conversion of process waste heat is described for typical applications in oil refineries and chemical plants. The s6stem is gesigned to produce electric power from waste heat available in a temperature range from 180 F to 400 F. The design of a new ORC turbogenerator uniquely adapted to applications of this type is presented. The unit has been designed for power outputs from 3/4 to 2~ MW and turbine inlet temperatures frQm 170 0 to 260 F. The machine design has eliminated the need for shaft seals, shaft couplings and the usual lube oil console normally required for turbine-generator units. Results of prototype tests of a 1 MW unit are presented. A product package and recommended division of responsibilities between purchaser, A&E company and supplier is presented for installations in refineries and process plants. The product package covers the electrical power range from 3/4 to 5 MW and waste heat streams from 20 to 130 million BTU/hr. INTRODUCTION The use of Organic Rankine Cycles (ORC) for the recovery and conversion of low-temperature waste heat has received considerable attention during recent years. The subject of which fluid is best suited for ORC systems has been exhaustively ana lyzed, and proponents of about five fluids have established their positions. A few demonstrator systems have been developed and put into service in diverse applications. However, only a small number of such units are now in service, and only a small fraction of the energy-conserving benefits of the concept have been realized to date. This is due in part to the fact that energy costs have only recently risen to the point where such units pro vide acceptable return on investment. A second contributing factor may be that the design of ORC equipment has not yet responded to the special needs of the dominant market for ORC systems. The ORC concept has the potential for a broad diversity of applications. These range from glass furnace exhaust gases at over 10000F to paper mill cooling-water effluent at l400F. However, two industries have the greatest potential application for ORC low-temperature waste heat recovery systems: the petroleum refining industry and the chemical industry. A study conducted by Resource Planning Asso ciates, Inc. [lJ *examined twenty u.S. industries to assess the application potential for ORC systems. These twenty were reduced in number to five Standard Industrial Code (SIC) industries having the highest potential for ORC penetration. These five are shown in Table 1, with the application potential of each. TABLE 1 MARKET POTENTIAL FOR ORC SYSTEMS Technical Market Potential Potential Market Industry (MW) (l1W) Potential Petroleum and Coal Products 1679 1407 67.9 Chemicals and A llied Products 1083 554 26.7 Stone, Clay and Glass Products 267 81 3.9 Paper and A llied Products 15 2 0.1 Primary Metal Industries 178 29 1.4 Proceedings from the Third Industrial Energy Technology Conference Houston, TX, April 26-29, 1981 516 TOTAL 3222 MW 2073 MW 100% Clearly, two industries constitute almost 95 percent of the available market. It should also be noted that of the technical market found in these two industries, 71 percent was judged to be economically A vg. Economic ESL-IE-81-04-90 Avg. % of Market EconomicPDF Image | ORC WASTE HEAT RECOVERY IN REFINERIES AND CHEMICAL Process

PDF Search Title:

ORC WASTE HEAT RECOVERY IN REFINERIES AND CHEMICAL ProcessOriginal File Name Searched:

ESL_IE_81_04_90.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |