PDF Publication Title:

Text from PDF Page: 004

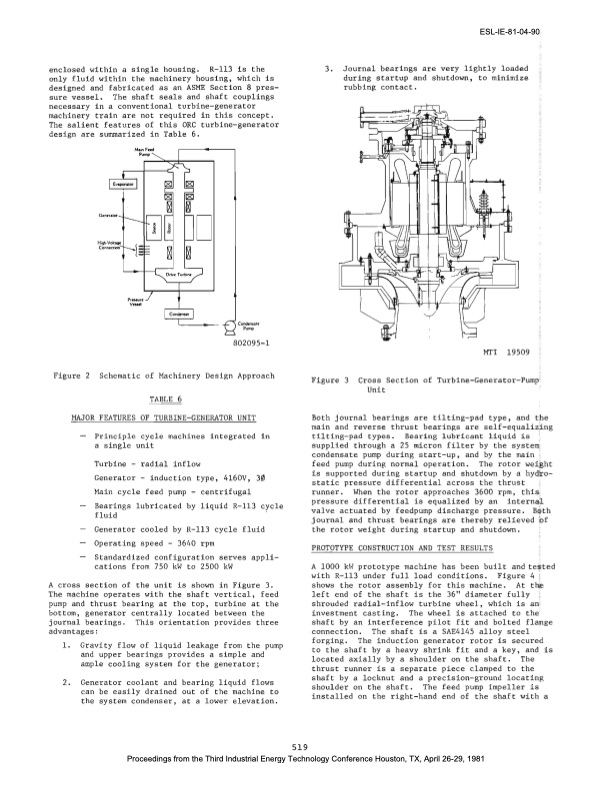

ESL-IE-81-04-90 enclosed within a single housing. R-113 is the only fluid within the machinery housing, which is designed and fabricated as an ASME Section 8 pres sure vessel. The shaft seals and shaft couplings necessary in a conventional turbine-generator machinery train are not required in this concept. The salient features of this ORC turbine-generator design are summarized in Table 6. D Figure 2 Schematic of Machinery Design Approach TABLE 6 MAJOR FEATURES OF TURBINE-GENERATOR UNIT Principle cycle machines integrated in a single unit Turbine - radial inflow Generator - induction type, 4l60V, 30 Main cycle feed pump - centrifugal Bearings lubricated by liquid R-113 cycle fluid Generator cooled by R-113 cycle fluid Operating speed - 3640 rpm Standardized configuration serves appli cations from 750 kW to 2500 kW A cross section of the unit is shown in Figure 3. The machine operates with the shaft vertical, feed pump and thrust bearing at the top, turbine at the bottom, generator centrally located between the journal bearings. This orientation provides three advantages: 1. Gravity flow of liquid leakage from the pump and upper bearings provides a simple and ample cooling system for the generator; 2. Generator coolant and bearing liquid flows can be easily drained out of the machine to the system condenser, at a lower elevation. 3. Journal bearings are very lightly loaded during startup and shutdown, to minimize rubbing contact. 802095-1 MTl 19509 Figure 3 Cross Section of Turbine-Generator-Pumpl Unit Both journal bearings are tilting-pad type, and tI"Je main and reverse thrust bearings are self-equaliz~ng tilting-pad types. Bearing lubricant liquid is ! supplied through a 25 micron filter by the syste~ condensate pump during start-up, and by the main i feed pump during normal operation. The rotor wei~ht is supported during startup and shutdown by a hyd~o static pressure differential across the thrust i runner. When the rotor approaches 3600 rpm, this! pressure differential is equalized by an internwl valve actuated by feedpump discharge pressure. B~th journal and thrust bearings are thereby relieved pf the rotor weight during startup and shutdown. PROTOTYPE CONSTRUCTION AND TEST RESULTS , A 1000 kH prototype machine has been built and tested with R-113 under full load conditions. Figure 4 I shows the rotor assembly for this machine. At t~ left end of the shaft is the 36" diameter fully i shrouded radial-inflow turbine wheel, which is am investment casting. The wheel is attached to the' shaft by an interference pilot fit and bolted flange connection. The shaft is a SAE4l45 alloy steel forging. The induction generator rotor is secured to the shaft by a heavy shrink fit and a key, and, is located axially by a shoulder on the shaft. The' thrust runner is a separate piece clamped to the shaft by a locknut and a precision-ground locating shoulder on the shaft. The feed pump impeller is installed on the right-hand end of the shaft with a 519 Proceedings from the Third Industrial Energy Technology Conference Houston, TX, April 26-29, 1981PDF Image | ORC WASTE HEAT RECOVERY IN REFINERIES AND CHEMICAL Process

PDF Search Title:

ORC WASTE HEAT RECOVERY IN REFINERIES AND CHEMICAL ProcessOriginal File Name Searched:

ESL_IE_81_04_90.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |