PDF Publication Title:

Text from PDF Page: 002

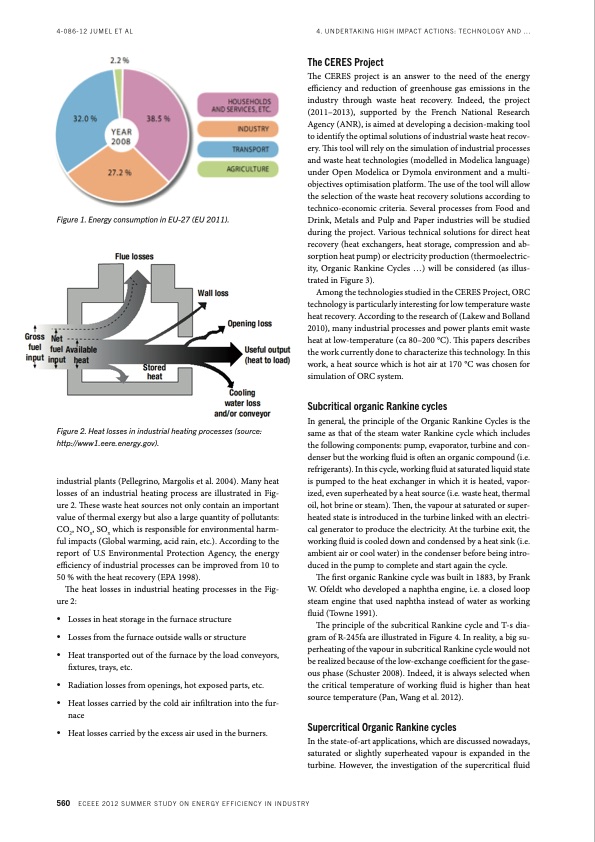

4-086-12 JUMEL ET AL 4. UNDERTAKING HIGH IMPACT ACTIONS: TECHNOLOGY AND ... Figure 1. Energy consumption in EU-27 (EU 2011). The CERES Project The CERES project is an answer to the need of the energy efficiency and reduction of greenhouse gas emissions in the industry through waste heat recovery. Indeed, the project (2011–2013), supported by the French National Research Agency (ANR), is aimed at developing a decision-making tool to identify the optimal solutions of industrial waste heat recov- ery. This tool will rely on the simulation of industrial processes and waste heat technologies (modelled in Modelica language) under Open Modelica or Dymola environment and a multi- objectives optimisation platform. The use of the tool will allow the selection of the waste heat recovery solutions according to technico-economic criteria. Several processes from Food and Drink, Metals and Pulp and Paper industries will be studied during the project. Various technical solutions for direct heat recovery (heat exchangers, heat storage, compression and ab- sorption heat pump) or electricity production (thermoelectric- ity, Organic Rankine Cycles ...) will be considered (as illus- trated in Figure 3). Among the technologies studied in the CERES Project, ORC technology is particularly interesting for low temperature waste heat recovery. According to the research of (Lakew and Bolland 2010), many industrial processes and power plants emit waste heat at low-temperature (ca 80–200 °C). This papers describes the work currently done to characterize this technology. In this work, a heat source which is hot air at 170 °C was chosen for simulation of ORC system. Subcritical organic Rankine cycles In general, the principle of the Organic Rankine Cycles is the same as that of the steam water Rankine cycle which includes the following components: pump, evaporator, turbine and con- denser but the working fluid is often an organic compound (i.e. refrigerants). In this cycle, working fluid at saturated liquid state is pumped to the heat exchanger in which it is heated, vapor- ized, even superheated by a heat source (i.e. waste heat, thermal oil, hot brine or steam). Then, the vapour at saturated or super- heated state is introduced in the turbine linked with an electri- cal generator to produce the electricity. At the turbine exit, the working fluid is cooled down and condensed by a heat sink (i.e. ambient air or cool water) in the condenser before being intro- duced in the pump to complete and start again the cycle. The first organic Rankine cycle was built in 1883, by Frank W. Ofeldt who developed a naphtha engine, i.e. a closed loop steam engine that used naphtha instead of water as working fluid (Towne 1991). The principle of the subcritical Rankine cycle and T-s dia- gram of R-245fa are illustrated in Figure 4. In reality, a big su- perheating of the vapour in subcritical Rankine cycle would not be realized because of the low-exchange coefficient for the gase- ous phase (Schuster 2008). Indeed, it is always selected when the critical temperature of working fluid is higher than heat source temperature (Pan, Wang et al. 2012). Supercritical Organic Rankine cycles In the state-of-art applications, which are discussed nowadays, saturated or slightly superheated vapour is expanded in the turbine. However, the investigation of the supercritical fluid Figure 2. Heat losses in industrial heating processes (source: http://www1.eere.energy.gov). industrial plants (Pellegrino, Margolis et al. 2004). Many heat losses of an industrial heating process are illustrated in Fig- ure 2. These waste heat sources not only contain an important value of thermal exergy but also a large quantity of pollutants: CO2, NOx, SOx which is responsible for environmental harm- ful impacts (Global warming, acid rain, etc.). According to the report of U.S Environmental Protection Agency, the energy efficiency of industrial processes can be improved from 10 to 50 % with the heat recovery (EPA 1998). The heat losses in industrial heating processes in the Fig- ure 2: • Losses in heat storage in the furnace structure • Losses from the furnace outside walls or structure • Heat transported out of the furnace by the load conveyors, fixtures, trays, etc. • Radiation losses from openings, hot exposed parts, etc. • Heat losses carried by the cold air infiltration into the fur- nace • Heat losses carried by the excess air used in the burners. 560 ECEEE 2012 SUMMER STUDY on EnERgY EffiCiEnCY in inDUSTRYPDF Image | Working Fluid selection and performance comparison of subcritical and supercritical organic Rankine cycle (ORC) for low temperature waste heat recovery

PDF Search Title:

Working Fluid selection and performance comparison of subcritical and supercritical organic Rankine cycle (ORC) for low temperature waste heat recoveryOriginal File Name Searched:

4_086_12_Jumel.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |