PDF Publication Title:

Text from PDF Page: 002

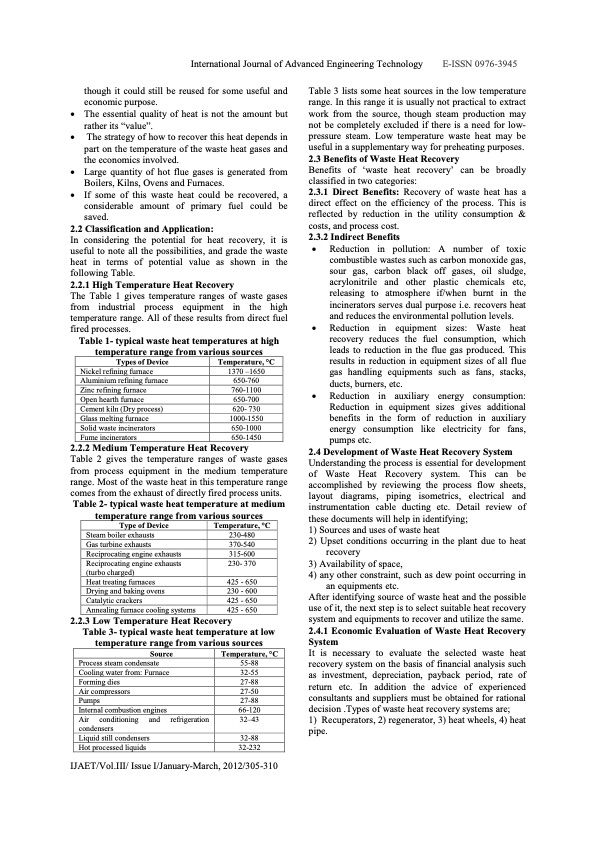

though it could still be reused for some useful and economic purpose. • The essential quality of heat is not the amount but rather its “value”. • The strategy of how to recover this heat depends in part on the temperature of the waste heat gases and the economics involved. • Large quantity of hot flue gases is generated from Boilers, Kilns, Ovens and Furnaces. • If some of this waste heat could be recovered, a considerable amount of primary fuel could be saved. 2.2 Classification and Application: In considering the potential for heat recovery, it is useful to note all the possibilities, and grade the waste heat in terms of potential value as shown in the following Table. 2.2.1 High Temperature Heat Recovery The Table 1 gives temperature ranges of waste gases from industrial process equipment in the high temperature range. All of these results from direct fuel fired processes. Table 1- typical waste heat temperatures at high temperature range from various sources Table 3 lists some heat sources in the low temperature range. In this range it is usually not practical to extract work from the source, though steam production may not be completely excluded if there is a need for low- pressure steam. Low temperature waste heat may be useful in a supplementary way for preheating purposes. 2.3 Benefits of Waste Heat Recovery Benefits of ‘waste heat recovery’ can be broadly classified in two categories: 2.3.1 Direct Benefits: Recovery of waste heat has a direct effect on the efficiency of the process. This is reflected by reduction in the utility consumption & costs, and process cost. 2.3.2 Indirect Benefits • Reduction in pollution: A number of toxic combustible wastes such as carbon monoxide gas, sour gas, carbon black off gases, oil sludge, acrylonitrile and other plastic chemicals etc, releasing to atmosphere if/when burnt in the incinerators serves dual purpose i.e. recovers heat and reduces the environmental pollution levels. • Reduction in equipment sizes: Waste heat recovery reduces the fuel consumption, which leads to reduction in the flue gas produced. This results in reduction in equipment sizes of all flue gas handling equipments such as fans, stacks, ducts, burners, etc. • Reduction in auxiliary energy consumption: Reduction in equipment sizes gives additional benefits in the form of reduction in auxiliary energy consumption like electricity for fans, pumps etc. 2.4 Development of Waste Heat Recovery System Understanding the process is essential for development of Waste Heat Recovery system. This can be accomplished by reviewing the process flow sheets, layout diagrams, piping isometrics, electrical and instrumentation cable ducting etc. Detail review of these documents will help in identifying; 1) Sources and uses of waste heat 2) Upset conditions occurring in the plant due to heat recovery 3) Availability of space, 4) any other constraint, such as dew point occurring in an equipments etc. After identifying source of waste heat and the possible use of it, the next step is to select suitable heat recovery system and equipments to recover and utilize the same. 2.4.1 Economic Evaluation of Waste Heat Recovery System It is necessary to evaluate the selected waste heat recovery system on the basis of financial analysis such as investment, depreciation, payback period, rate of return etc. In addition the advice of experienced consultants and suppliers must be obtained for rational decision .Types of waste heat recovery systems are; 1) Recuperators, 2) regenerator, 3) heat wheels, 4) heat pipe. Types of Device Nickel refining furnace Aluminium refining furnace Zinc refining furnace Open hearth furnace Cement kiln (Dry process) Glass melting furnace Solid waste incinerators Fume incinerators Temperature, °C 1370 –1650 650-760 760-1100 650-700 620- 730 1000-1550 650-1000 650-1450 International Journal of Advanced Engineering Technology E-ISSN 0976-3945 2.2.2 Medium Temperature Heat Recovery Table 2 gives the temperature ranges of waste gases from process equipment in the medium temperature range. Most of the waste heat in this temperature range comes from the exhaust of directly fired process units. Table 2- typical waste heat temperature at medium temperature range from various sources Type of Device Steam boiler exhausts Gas turbine exhausts Reciprocating engine exhausts Reciprocating engine exhausts (turbo charged) Heat treating furnaces Drying and baking ovens Catalytic crackers Annealing furnace cooling systems Temperature, °C 230-480 370-540 315-600 230- 370 425 - 650 230 - 600 425 - 650 425 - 650 2.2.3 Low Temperature Heat Recovery Table 3- typical waste heat temperature at low temperature range from various sources Source Process steam condensate Cooling water from: Furnace Forming dies Air compressors Pumps Internal combustion engines Air conditioning and refrigeration condensers Liquid still condensers Hot processed liquids Temperature, °C 55-88 32-55 27-88 27-50 27-88 66-120 32–43 32-88 32-232 IJAET/Vol.III/ Issue I/January-March, 2012/305-310PDF Image | Research Paper WASTE HEAT RECOVERY USING STIRLING ENGINE

PDF Search Title:

Research Paper WASTE HEAT RECOVERY USING STIRLING ENGINEOriginal File Name Searched:

68_IJAET_Vol_III_Issue_I_2012.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |