PDF Publication Title:

Text from PDF Page: 003

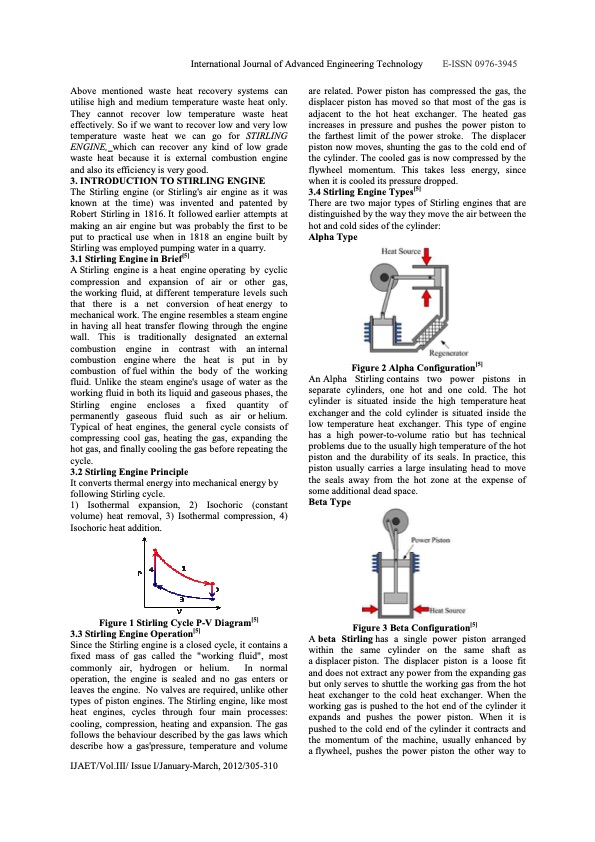

Above mentioned waste heat recovery systems can utilise high and medium temperature waste heat only. They cannot recover low temperature waste heat effectively. So if we want to recover low and very low temperature waste heat we can go for STIRLING ENGINE, which can recover any kind of low grade waste heat because it is external combustion engine and also its efficiency is very good. 3. INTRODUCTION TO STIRLING ENGINE The Stirling engine (or Stirling's air engine as it was known at the time) was invented and patented by Robert Stirling in 1816. It followed earlier attempts at making an air engine but was probably the first to be put to practical use when in 1818 an engine built by Stirling was employed pumping water in a quarry. 3.1 Stirling Engine in Brief[5] A Stirling engine is a heat engine operating by cyclic compression and expansion of air or other gas, the working fluid, at different temperature levels such that there is a net conversion of heat energy to mechanical work. The engine resembles a steam engine in having all heat transfer flowing through the engine wall. This is traditionally designated an external combustion engine in contrast with an internal combustion enginewhere the heat is put in by combustion of fuel within the body of the working fluid. Unlike the steam engine's usage of water as the working fluid in both its liquid and gaseous phases, the Stirling engine encloses a fixed quantity of permanently gaseous fluid such as air orhelium. Typical of heat engines, the general cycle consists of compressing cool gas, heating the gas, expanding the hot gas, and finally cooling the gas before repeating the cycle. 3.2 Stirling Engine Principle It converts thermal energy into mechanical energy by following Stirling cycle. 1) Isothermal expansion, 2) Isochoric (constant volume) heat removal, 3) Isothermal compression, 4) Isochoric heat addition. Figure 1 Stirling Cycle P-V Diagram[5] 3.3 Stirling Engine Operation[5] Since the Stirling engine is a closed cycle, it contains a fixed mass of gas called the "working fluid", most commonly air, hydrogen or helium. In normal operation, the engine is sealed and no gas enters or leaves the engine. No valves are required, unlike other types of piston engines. The Stirling engine, like most heat engines, cycles through four main processes: cooling, compression, heating and expansion. The gas follows the behaviour described by the gas laws which describe how a gas'pressure, temperature and volume are related. Power piston has compressed the gas, the displacer piston has moved so that most of the gas is adjacent to the hot heat exchanger. The heated gas increases in pressure and pushes the power piston to the farthest limit of the power stroke. The displacer piston now moves, shunting the gas to the cold end of the cylinder. The cooled gas is now compressed by the flywheel momentum. This takes less energy, since when it is cooled its pressure dropped. 3.4 Stirling Engine Types[5] There are two major types of Stirling engines that are distinguished by the way they move the air between the hot and cold sides of the cylinder: Alpha Type Figure 2 Alpha Configuration[5] International Journal of Advanced Engineering Technology E-ISSN 0976-3945 An Alpha separate cylinders, one hot and one cold. The hot cylinder is situated inside the high temperature heat exchanger and the cold cylinder is situated inside the low temperature heat exchanger. This type of engine has a high power-to-volume ratio but has technical problems due to the usually high temperature of the hot piston and the durability of its seals. In practice, this piston usually carries a large insulating head to move the seals away from the hot zone at the expense of some additional dead space. Beta Type [5] Figure 3 Beta Configuration Stirling contains two power pistons in IJAET/Vol.III/ Issue I/January-March, 2012/305-310 A beta within the same cylinder on the same shaft as a displacer piston. The displacer piston is a loose fit and does not extract any power from the expanding gas but only serves to shuttle the working gas from the hot heat exchanger to the cold heat exchanger. When the working gas is pushed to the hot end of the cylinder it expands and pushes the power piston. When it is pushed to the cold end of the cylinder it contracts and the momentum of the machine, usually enhanced by a flywheel, pushes the power piston the other way to Stirling has a single power piston arrangedPDF Image | Research Paper WASTE HEAT RECOVERY USING STIRLING ENGINE

PDF Search Title:

Research Paper WASTE HEAT RECOVERY USING STIRLING ENGINEOriginal File Name Searched:

68_IJAET_Vol_III_Issue_I_2012.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |