PDF Publication Title:

Text from PDF Page: 090

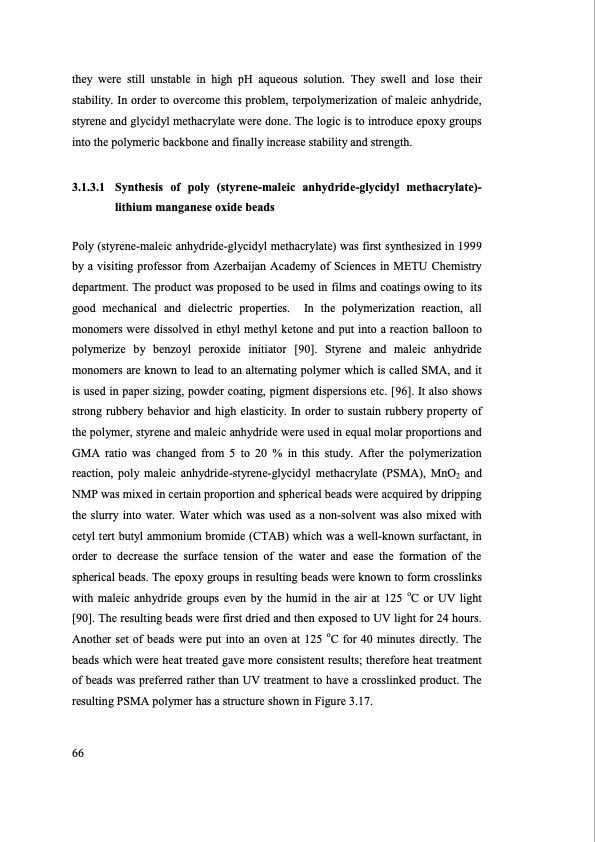

they were still unstable in high pH aqueous solution. They swell and lose their stability. In order to overcome this problem, terpolymerization of maleic anhydride, styrene and glycidyl methacrylate were done. The logic is to introduce epoxy groups into the polymeric backbone and finally increase stability and strength. 3.1.3.1 Synthesis of poly (styrene-maleic anhydride-glycidyl methacrylate)- lithium manganese oxide beads Poly (styrene-maleic anhydride-glycidyl methacrylate) was first synthesized in 1999 by a visiting professor from Azerbaijan Academy of Sciences in METU Chemistry department. The product was proposed to be used in films and coatings owing to its good mechanical and dielectric properties. In the polymerization reaction, all monomers were dissolved in ethyl methyl ketone and put into a reaction balloon to polymerize by benzoyl peroxide initiator [90]. Styrene and maleic anhydride monomers are known to lead to an alternating polymer which is called SMA, and it is used in paper sizing, powder coating, pigment dispersions etc. [96]. It also shows strong rubbery behavior and high elasticity. In order to sustain rubbery property of the polymer, styrene and maleic anhydride were used in equal molar proportions and GMA ratio was changed from 5 to 20 % in this study. After the polymerization reaction, poly maleic anhydride-styrene-glycidyl methacrylate (PSMA), MnO2 and NMP was mixed in certain proportion and spherical beads were acquired by dripping the slurry into water. Water which was used as a non-solvent was also mixed with cetyl tert butyl ammonium bromide (CTAB) which was a well-known surfactant, in order to decrease the surface tension of the water and ease the formation of the spherical beads. The epoxy groups in resulting beads were known to form crosslinks with maleic anhydride groups even by the humid in the air at 125 oC or UV light [90]. The resulting beads were first dried and then exposed to UV light for 24 hours. Another set of beads were put into an oven at 125 oC for 40 minutes directly. The beads which were heat treated gave more consistent results; therefore heat treatment of beads was preferred rather than UV treatment to have a crosslinked product. The resulting PSMA polymer has a structure shown in Figure 3.17. 66PDF Image | SEPARATION OF LITHIUM FROM BRINES

PDF Search Title:

SEPARATION OF LITHIUM FROM BRINESOriginal File Name Searched:

separation-lithium-from-brine.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |