PDF Publication Title:

Text from PDF Page: 089

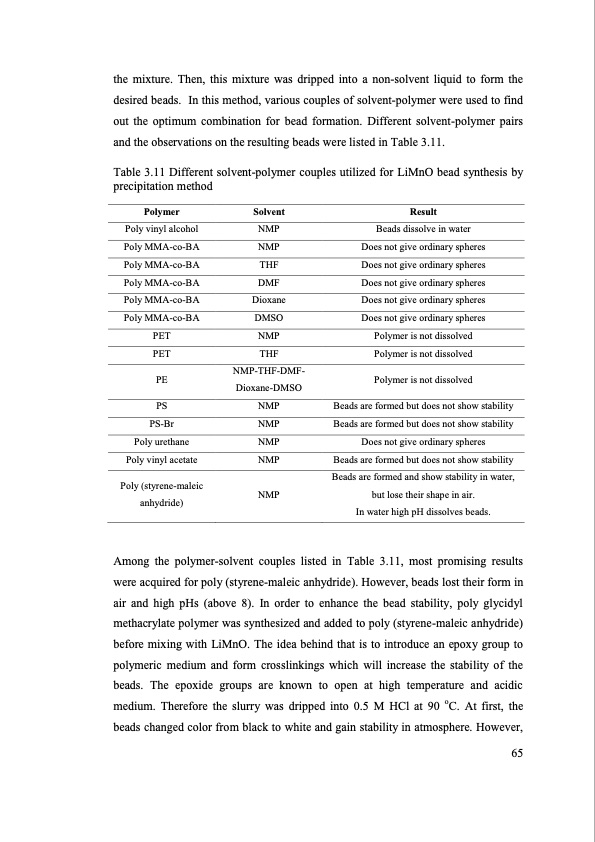

the mixture. Then, this mixture was dripped into a non-solvent liquid to form the desired beads. In this method, various couples of solvent-polymer were used to find out the optimum combination for bead formation. Different solvent-polymer pairs and the observations on the resulting beads were listed in Table 3.11. Table 3.11 Different solvent-polymer couples utilized for LiMnO bead synthesis by precipitation method Polymer Solvent Poly vinyl alcohol NMP Poly MMA-co-BA NMP Poly MMA-co-BA THF Poly MMA-co-BA DMF Poly MMA-co-BA Dioxane Poly MMA-co-BA DMSO PET NMP PET THF PE NMP-THF-DMF- Dioxane-DMSO PS NMP PS-Br NMP Poly urethane NMP Poly vinyl acetate NMP Result Beads dissolve in water Does not give ordinary spheres Does not give ordinary spheres Does not give ordinary spheres Does not give ordinary spheres Does not give ordinary spheres Polymer is not dissolved Polymer is not dissolved Polymer is not dissolved Beads are formed but does not show stability Beads are formed but does not show stability Does not give ordinary spheres Beads are formed but does not show stability Beads are formed and show stability in water, but lose their shape in air. In water high pH dissolves beads. Poly (styrene-maleic anhydride) NMP Among the polymer-solvent couples listed in Table 3.11, most promising results were acquired for poly (styrene-maleic anhydride). However, beads lost their form in air and high pHs (above 8). In order to enhance the bead stability, poly glycidyl methacrylate polymer was synthesized and added to poly (styrene-maleic anhydride) before mixing with LiMnO. The idea behind that is to introduce an epoxy group to polymeric medium and form crosslinkings which will increase the stability of the beads. The epoxide groups are known to open at high temperature and acidic medium. Therefore the slurry was dripped into 0.5 M HCl at 90 oC. At first, the beads changed color from black to white and gain stability in atmosphere. However, 65PDF Image | SEPARATION OF LITHIUM FROM BRINES

PDF Search Title:

SEPARATION OF LITHIUM FROM BRINESOriginal File Name Searched:

separation-lithium-from-brine.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |