PDF Publication Title:

Text from PDF Page: 053

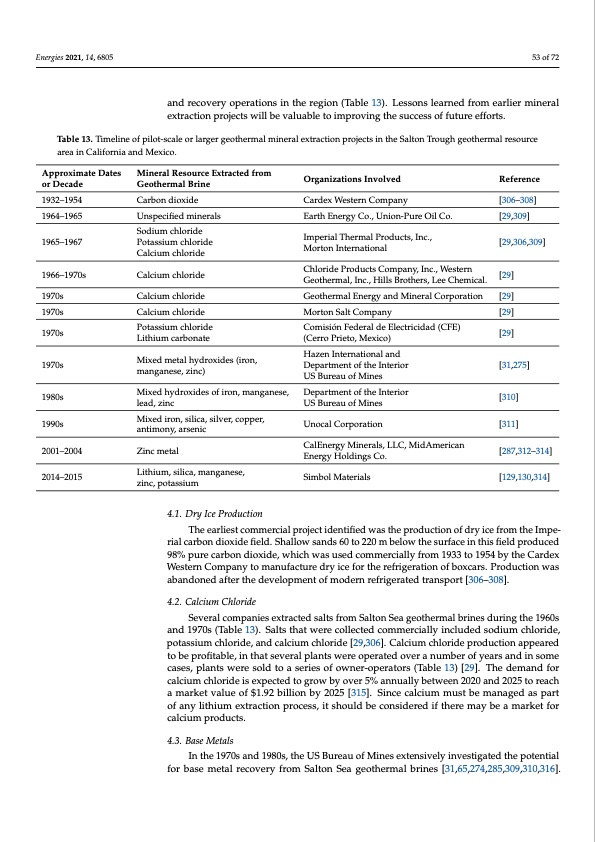

Energies 2021, 14, 6805 53 of 72 and recovery operations in the region (Table 13). Lessons learned from earlier mineral extraction projects will be valuable to improving the success of future efforts. Table 13. Timeline of pilot-scale or larger geothermal mineral extraction projects in the Salton Trough geothermal resource area in California and Mexico. Approximate Dates or Decade 1932–1954 1964–1965 1965–1967 1966–1970s 1970s 1970s 1970s 1970s 1980s 1990s 2001–2004 2014–2015 Mineral Resource Extracted from Geothermal Brine Carbon dioxide Unspecified minerals Sodium chloride Potassium chloride Calcium chloride Calcium chloride Calcium chloride Calcium chloride Potassium chloride Lithium carbonate Mixed metal hydroxides (iron, manganese, zinc) Mixed hydroxides of iron, manganese, lead, zinc Mixed iron, silica, silver, copper, antimony, arsenic Zinc metal Lithium, silica, manganese, zinc, potassium 4.1. Dry Ice Production Organizations Involved Cardex Western Company Earth Energy Co., Union-Pure Oil Co. Imperial Thermal Products, Inc., Morton International Chloride Products Company, Inc., Western Geothermal, Inc., Hills Brothers, Lee Chemical. Geothermal Energy and Mineral Corporation Morton Salt Company Comisión Federal de Electricidad (CFE) (Cerro Prieto, Mexico) Hazen International and Department of the Interior US Bureau of Mines Department of the Interior US Bureau of Mines Unocal Corporation CalEnergy Minerals, LLC, MidAmerican Energy Holdings Co. Simbol Materials Reference [306–308] [29,309] [29,306,309] [29] [29] [29] [29] [31,275] [310] [311] [287,312–314] [129,130,314] The earliest commercial project identified was the production of dry ice from the Impe- rial carbon dioxide field. Shallow sands 60 to 220 m below the surface in this field produced 98% pure carbon dioxide, which was used commercially from 1933 to 1954 by the Cardex Western Company to manufacture dry ice for the refrigeration of boxcars. Production was abandoned after the development of modern refrigerated transport [306–308]. 4.2. Calcium Chloride Several companies extracted salts from Salton Sea geothermal brines during the 1960s and 1970s (Table 13). Salts that were collected commercially included sodium chloride, potassium chloride, and calcium chloride [29,306]. Calcium chloride production appeared to be profitable, in that several plants were operated over a number of years and in some cases, plants were sold to a series of owner-operators (Table 13) [29]. The demand for calcium chloride is expected to grow by over 5% annually between 2020 and 2025 to reach a market value of $1.92 billion by 2025 [315]. Since calcium must be managed as part of any lithium extraction process, it should be considered if there may be a market for calcium products. 4.3. Base Metals In the 1970s and 1980s, the US Bureau of Mines extensively investigated the potential for base metal recovery from Salton Sea geothermal brines [31,65,274,285,309,310,316].PDF Image | Recovery of Lithium from Geothermal Brines

PDF Search Title:

Recovery of Lithium from Geothermal BrinesOriginal File Name Searched:

energies-14-06805-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |