PDF Publication Title:

Text from PDF Page: 042

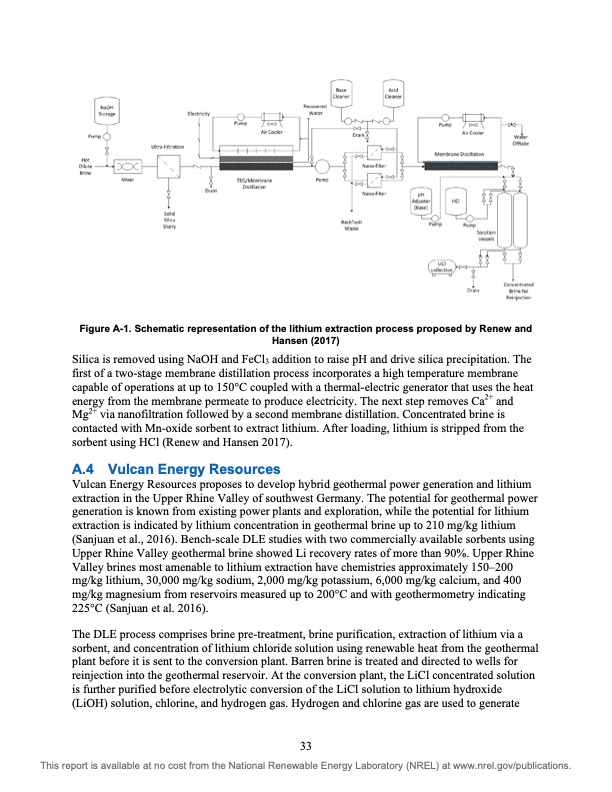

Figure A-1. Schematic representation of the lithium extraction process proposed by Renew and Hansen (2017) Silica is removed using NaOH and FeCl3 addition to raise pH and drive silica precipitation. The first of a two-stage membrane distillation process incorporates a high temperature membrane capable of operations at up to 150°C coupled with a thermal-electric generator that uses the heat energy from the membrane permeate to produce electricity. The next step removes Ca2+ and Mg2+ via nanofiltration followed by a second membrane distillation. Concentrated brine is contacted with Mn-oxide sorbent to extract lithium. After loading, lithium is stripped from the sorbent using HCl (Renew and Hansen 2017). A.4 Vulcan Energy Resources Vulcan Energy Resources proposes to develop hybrid geothermal power generation and lithium extraction in the Upper Rhine Valley of southwest Germany. The potential for geothermal power generation is known from existing power plants and exploration, while the potential for lithium extraction is indicated by lithium concentration in geothermal brine up to 210 mg/kg lithium (Sanjuan et al., 2016). Bench-scale DLE studies with two commercially available sorbents using Upper Rhine Valley geothermal brine showed Li recovery rates of more than 90%. Upper Rhine Valley brines most amenable to lithium extraction have chemistries approximately 150–200 mg/kg lithium, 30,000 mg/kg sodium, 2,000 mg/kg potassium, 6,000 mg/kg calcium, and 400 mg/kg magnesium from reservoirs measured up to 200°C and with geothermometry indicating 225°C (Sanjuan et al. 2016). The DLE process comprises brine pre-treatment, brine purification, extraction of lithium via a sorbent, and concentration of lithium chloride solution using renewable heat from the geothermal plant before it is sent to the conversion plant. Barren brine is treated and directed to wells for reinjection into the geothermal reservoir. At the conversion plant, the LiCl concentrated solution is further purified before electrolytic conversion of the LiCl solution to lithium hydroxide (LiOH) solution, chlorine, and hydrogen gas. Hydrogen and chlorine gas are used to generate 33 This report is available at no cost from the National Renewable Energy Laboratory (NREL) at www.nrel.gov/publications.PDF Image | Lithium Extraction from Geothermal Brines

PDF Search Title:

Lithium Extraction from Geothermal BrinesOriginal File Name Searched:

79178.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |