PDF Publication Title:

Text from PDF Page: 043

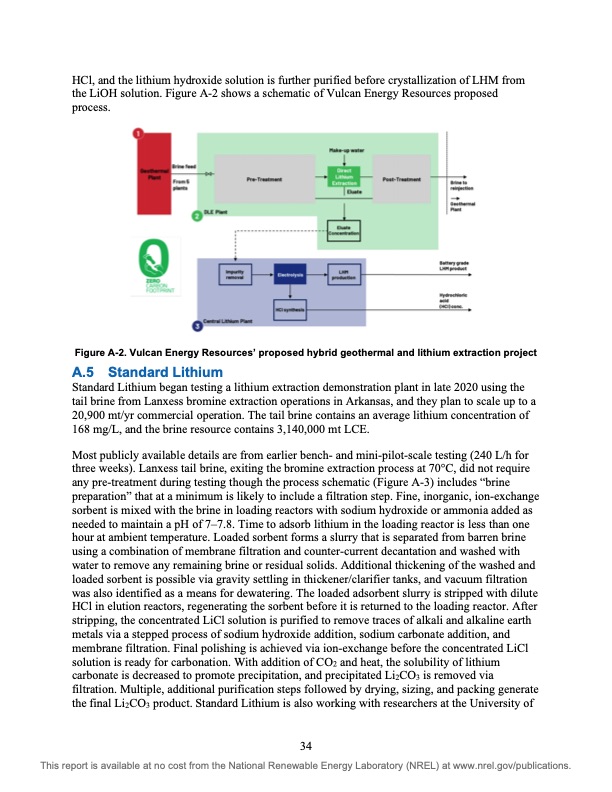

HCl, and the lithium hydroxide solution is further purified before crystallization of LHM from the LiOH solution. Figure A-2 shows a schematic of Vulcan Energy Resources proposed process. Figure A-2. Vulcan Energy Resources’ proposed hybrid geothermal and lithium extraction project A.5 Standard Lithium Standard Lithium began testing a lithium extraction demonstration plant in late 2020 using the tail brine from Lanxess bromine extraction operations in Arkansas, and they plan to scale up to a 20,900 mt/yr commercial operation. The tail brine contains an average lithium concentration of 168 mg/L, and the brine resource contains 3,140,000 mt LCE. Most publicly available details are from earlier bench- and mini-pilot-scale testing (240 L/h for three weeks). Lanxess tail brine, exiting the bromine extraction process at 70°C, did not require any pre-treatment during testing though the process schematic (Figure A-3) includes “brine preparation” that at a minimum is likely to include a filtration step. Fine, inorganic, ion-exchange sorbent is mixed with the brine in loading reactors with sodium hydroxide or ammonia added as needed to maintain a pH of 7–7.8. Time to adsorb lithium in the loading reactor is less than one hour at ambient temperature. Loaded sorbent forms a slurry that is separated from barren brine using a combination of membrane filtration and counter-current decantation and washed with water to remove any remaining brine or residual solids. Additional thickening of the washed and loaded sorbent is possible via gravity settling in thickener/clarifier tanks, and vacuum filtration was also identified as a means for dewatering. The loaded adsorbent slurry is stripped with dilute HCl in elution reactors, regenerating the sorbent before it is returned to the loading reactor. After stripping, the concentrated LiCl solution is purified to remove traces of alkali and alkaline earth metals via a stepped process of sodium hydroxide addition, sodium carbonate addition, and membrane filtration. Final polishing is achieved via ion-exchange before the concentrated LiCl solution is ready for carbonation. With addition of CO2 and heat, the solubility of lithium carbonate is decreased to promote precipitation, and precipitated Li2CO3 is removed via filtration. Multiple, additional purification steps followed by drying, sizing, and packing generate the final Li2CO3 product. Standard Lithium is also working with researchers at the University of 34 This report is available at no cost from the National Renewable Energy Laboratory (NREL) at www.nrel.gov/publications.PDF Image | Lithium Extraction from Geothermal Brines

PDF Search Title:

Lithium Extraction from Geothermal BrinesOriginal File Name Searched:

79178.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |