PDF Publication Title:

Text from PDF Page: 029

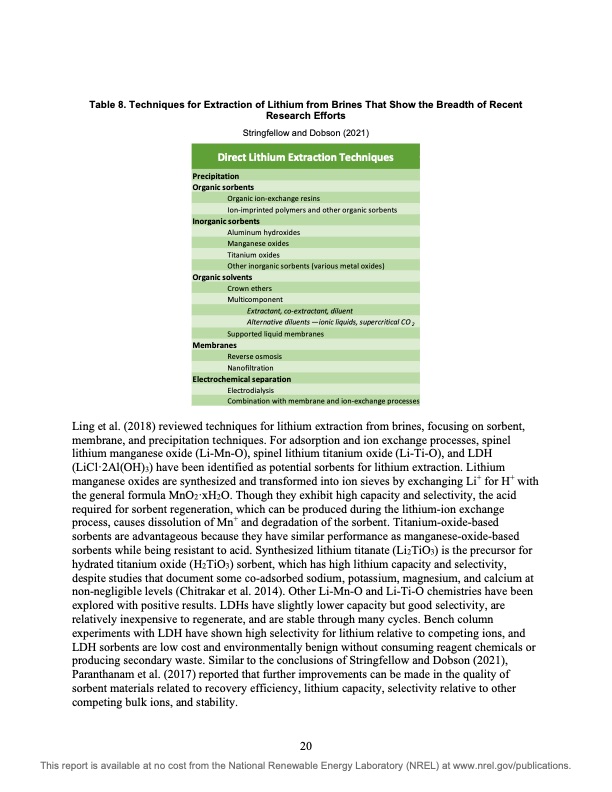

Table 8. Techniques for Extraction of Lithium from Brines That Show the Breadth of Recent Research Efforts Stringfellow and Dobson (2021) Direct Lithium Extraction Techniques Precipitation Organic sorbents Organic ion-exchange resins Ion-imprinted polymers and other organic sorbents Inorganic sorbents Aluminum hydroxides Manganese oxides Titanium oxides Other inorganic sorbents (various metal oxides) Organic solvents Crown ethers Multicomponent Extractant, co-extractant, diluent Alternative diluents —ionic liquids, supercritical CO 2 Supported liquid membranes Membranes Reverse osmosis Nanofiltration Electrochemical separation Electrodialysis Combination with membrane and ion-exchange processes Ling et al. (2018) reviewed techniques for lithium extraction from brines, focusing on sorbent, membrane, and precipitation techniques. For adsorption and ion exchange processes, spinel lithium manganese oxide (Li-Mn-O), spinel lithium titanium oxide (Li-Ti-O), and LDH (LiCl·2Al(OH)3) have been identified as potential sorbents for lithium extraction. Lithium manganese oxides are synthesized and transformed into ion sieves by exchanging Li+ for H+ with the general formula MnO2·xH2O. Though they exhibit high capacity and selectivity, the acid required for sorbent regeneration, which can be produced during the lithium-ion exchange process, causes dissolution of Mn+ and degradation of the sorbent. Titanium-oxide-based sorbents are advantageous because they have similar performance as manganese-oxide-based sorbents while being resistant to acid. Synthesized lithium titanate (Li2TiO3) is the precursor for hydrated titanium oxide (H2TiO3) sorbent, which has high lithium capacity and selectivity, despite studies that document some co-adsorbed sodium, potassium, magnesium, and calcium at non-negligible levels (Chitrakar et al. 2014). Other Li-Mn-O and Li-Ti-O chemistries have been explored with positive results. LDHs have slightly lower capacity but good selectivity, are relatively inexpensive to regenerate, and are stable through many cycles. Bench column experiments with LDH have shown high selectivity for lithium relative to competing ions, and LDH sorbents are low cost and environmentally benign without consuming reagent chemicals or producing secondary waste. Similar to the conclusions of Stringfellow and Dobson (2021), Paranthanam et al. (2017) reported that further improvements can be made in the quality of sorbent materials related to recovery efficiency, lithium capacity, selectivity relative to other competing bulk ions, and stability. 20 This report is available at no cost from the National Renewable Energy Laboratory (NREL) at www.nrel.gov/publications.PDF Image | Lithium Extraction from Geothermal Brines

PDF Search Title:

Lithium Extraction from Geothermal BrinesOriginal File Name Searched:

79178.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |