PDF Publication Title:

Text from PDF Page: 027

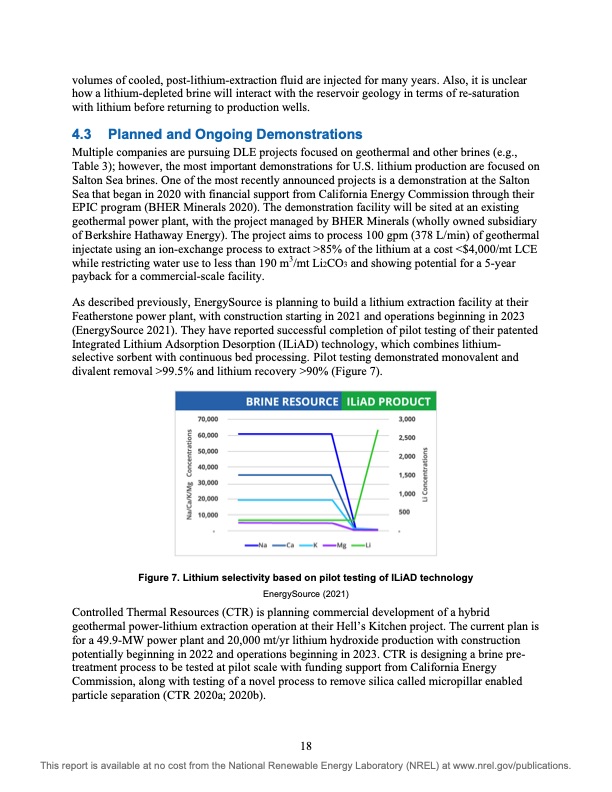

volumes of cooled, post-lithium-extraction fluid are injected for many years. Also, it is unclear how a lithium-depleted brine will interact with the reservoir geology in terms of re-saturation with lithium before returning to production wells. 4.3 Planned and Ongoing Demonstrations Multiple companies are pursuing DLE projects focused on geothermal and other brines (e.g., Table 3); however, the most important demonstrations for U.S. lithium production are focused on Salton Sea brines. One of the most recently announced projects is a demonstration at the Salton Sea that began in 2020 with financial support from California Energy Commission through their EPIC program (BHER Minerals 2020). The demonstration facility will be sited at an existing geothermal power plant, with the project managed by BHER Minerals (wholly owned subsidiary of Berkshire Hathaway Energy). The project aims to process 100 gpm (378 L/min) of geothermal injectate using an ion-exchange process to extract >85% of the lithium at a cost <$4,000/mt LCE while restricting water use to less than 190 m3/mt Li2CO3 and showing potential for a 5-year payback for a commercial-scale facility. As described previously, EnergySource is planning to build a lithium extraction facility at their Featherstone power plant, with construction starting in 2021 and operations beginning in 2023 (EnergySource 2021). They have reported successful completion of pilot testing of their patented Integrated Lithium Adsorption Desorption (ILiAD) technology, which combines lithium- selective sorbent with continuous bed processing. Pilot testing demonstrated monovalent and divalent removal >99.5% and lithium recovery >90% (Figure 7). Figure 7. Lithium selectivity based on pilot testing of ILiAD technology EnergySource (2021) Controlled Thermal Resources (CTR) is planning commercial development of a hybrid geothermal power-lithium extraction operation at their Hell’s Kitchen project. The current plan is for a 49.9-MW power plant and 20,000 mt/yr lithium hydroxide production with construction potentially beginning in 2022 and operations beginning in 2023. CTR is designing a brine pre- treatment process to be tested at pilot scale with funding support from California Energy Commission, along with testing of a novel process to remove silica called micropillar enabled particle separation (CTR 2020a; 2020b). 18 This report is available at no cost from the National Renewable Energy Laboratory (NREL) at www.nrel.gov/publications.PDF Image | Lithium Extraction from Geothermal Brines

PDF Search Title:

Lithium Extraction from Geothermal BrinesOriginal File Name Searched:

79178.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |