PDF Publication Title:

Text from PDF Page: 026

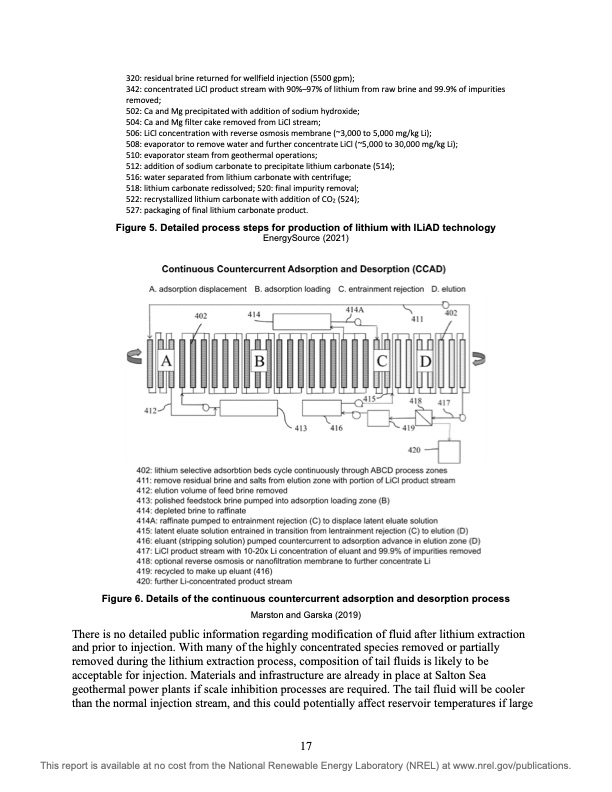

320: residual brine returned for wellfield injection (5500 gpm); 342: concentrated LiCl product stream with 90%–97% of lithium from raw brine and 99.9% of impurities removed; 502: Ca and Mg precipitated with addition of sodium hydroxide; 504: Ca and Mg filter cake removed from LiCl stream; 506: LiCl concentration with reverse osmosis membrane (~3,000 to 5,000 mg/kg Li); 508: evaporator to remove water and further concentrate LiCl (~5,000 to 30,000 mg/kg Li); 510: evaporator steam from geothermal operations; 512: addition of sodium carbonate to precipitate lithium carbonate (514); 516: water separated from lithium carbonate with centrifuge; 518: lithium carbonate redissolved; 520: final impurity removal; 522: recrystallized lithium carbonate with addition of CO2 (524); 527: packaging of final lithium carbonate product. Figure 5. Detailed process steps for production of lithium with ILiAD technology EnergySource (2021) Figure 6. Details of the continuous countercurrent adsorption and desorption process Marston and Garska (2019) There is no detailed public information regarding modification of fluid after lithium extraction and prior to injection. With many of the highly concentrated species removed or partially removed during the lithium extraction process, composition of tail fluids is likely to be acceptable for injection. Materials and infrastructure are already in place at Salton Sea geothermal power plants if scale inhibition processes are required. The tail fluid will be cooler than the normal injection stream, and this could potentially affect reservoir temperatures if large 17 This report is available at no cost from the National Renewable Energy Laboratory (NREL) at www.nrel.gov/publications.PDF Image | Lithium Extraction from Geothermal Brines

PDF Search Title:

Lithium Extraction from Geothermal BrinesOriginal File Name Searched:

79178.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |