PDF Publication Title:

Text from PDF Page: 016

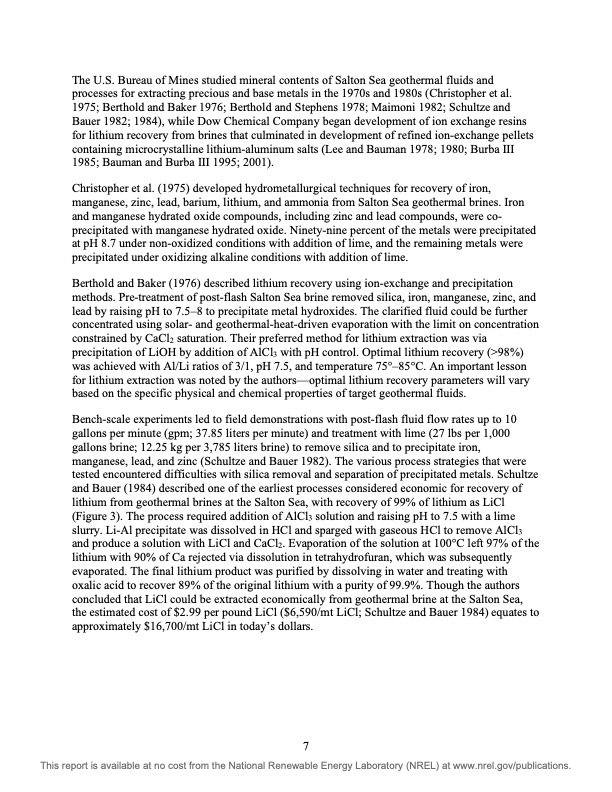

The U.S. Bureau of Mines studied mineral contents of Salton Sea geothermal fluids and processes for extracting precious and base metals in the 1970s and 1980s (Christopher et al. 1975; Berthold and Baker 1976; Berthold and Stephens 1978; Maimoni 1982; Schultze and Bauer 1982; 1984), while Dow Chemical Company began development of ion exchange resins for lithium recovery from brines that culminated in development of refined ion-exchange pellets containing microcrystalline lithium-aluminum salts (Lee and Bauman 1978; 1980; Burba III 1985; Bauman and Burba III 1995; 2001). Christopher et al. (1975) developed hydrometallurgical techniques for recovery of iron, manganese, zinc, lead, barium, lithium, and ammonia from Salton Sea geothermal brines. Iron and manganese hydrated oxide compounds, including zinc and lead compounds, were co- precipitated with manganese hydrated oxide. Ninety-nine percent of the metals were precipitated at pH 8.7 under non-oxidized conditions with addition of lime, and the remaining metals were precipitated under oxidizing alkaline conditions with addition of lime. Berthold and Baker (1976) described lithium recovery using ion-exchange and precipitation methods. Pre-treatment of post-flash Salton Sea brine removed silica, iron, manganese, zinc, and lead by raising pH to 7.5–8 to precipitate metal hydroxides. The clarified fluid could be further concentrated using solar- and geothermal-heat-driven evaporation with the limit on concentration constrained by CaCl2 saturation. Their preferred method for lithium extraction was via precipitation of LiOH by addition of AlCl3 with pH control. Optimal lithium recovery (>98%) was achieved with Al/Li ratios of 3/1, pH 7.5, and temperature 75°–85°C. An important lesson for lithium extraction was noted by the authors—optimal lithium recovery parameters will vary based on the specific physical and chemical properties of target geothermal fluids. Bench-scale experiments led to field demonstrations with post-flash fluid flow rates up to 10 gallons per minute (gpm; 37.85 liters per minute) and treatment with lime (27 lbs per 1,000 gallons brine; 12.25 kg per 3,785 liters brine) to remove silica and to precipitate iron, manganese, lead, and zinc (Schultze and Bauer 1982). The various process strategies that were tested encountered difficulties with silica removal and separation of precipitated metals. Schultze and Bauer (1984) described one of the earliest processes considered economic for recovery of lithium from geothermal brines at the Salton Sea, with recovery of 99% of lithium as LiCl (Figure 3). The process required addition of AlCl3 solution and raising pH to 7.5 with a lime slurry. Li-Al precipitate was dissolved in HCl and sparged with gaseous HCl to remove AlCl3 and produce a solution with LiCl and CaCl2. Evaporation of the solution at 100°C left 97% of the lithium with 90% of Ca rejected via dissolution in tetrahydrofuran, which was subsequently evaporated. The final lithium product was purified by dissolving in water and treating with oxalic acid to recover 89% of the original lithium with a purity of 99.9%. Though the authors concluded that LiCl could be extracted economically from geothermal brine at the Salton Sea, the estimated cost of $2.99 per pound LiCl ($6,590/mt LiCl; Schultze and Bauer 1984) equates to approximately $16,700/mt LiCl in today’s dollars. 7 This report is available at no cost from the National Renewable Energy Laboratory (NREL) at www.nrel.gov/publications.PDF Image | Lithium Extraction from Geothermal Brines

PDF Search Title:

Lithium Extraction from Geothermal BrinesOriginal File Name Searched:

79178.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |