PDF Publication Title:

Text from PDF Page: 020

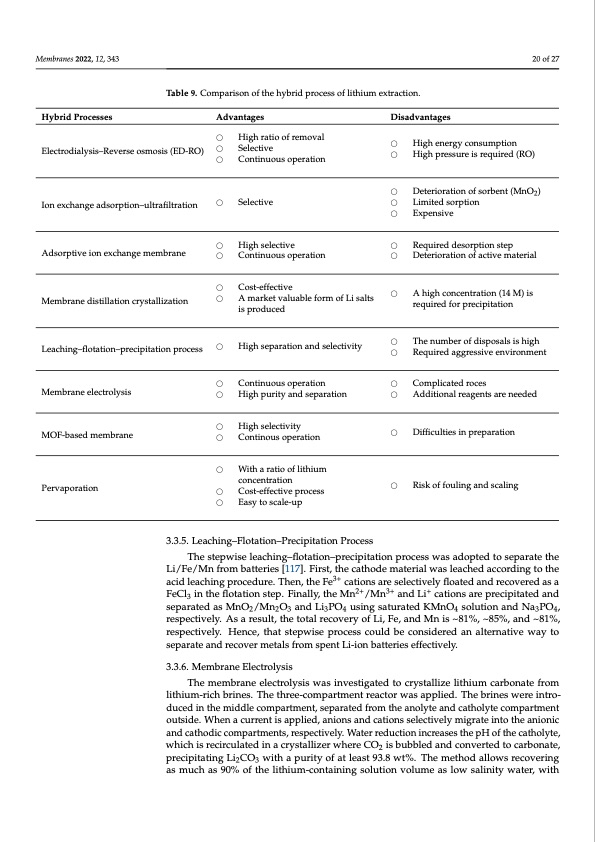

Membranes 2022, 12, 343 20 of 27 Hybrid Processes Table 9. Comparison of the hybrid process of lithium extraction. Advantages Disadvantages Electrodialysis–Reverse osmosis (ED-RO) High ratio of removal Selective Continuous operation Selective High selective Continuous operation Cost-effective A market valuable form of Li salts is produced High separation and selectivity Continuous operation High purity and separation High selectivity Continous operation With a ratio of lithium concentration Cost-effective process Easy to scale-up 3.3.5. Leaching–Flotation–Precipitation Process High energy consumption High pressure is required (RO) Deterioration of sorbent (MnO2 ) Limited sorption Expensive Required desorption step Deterioration of active material A high concentration (14 M) is required for precipitation The number of disposals is high Required aggressive environment Complicated roces Additional reagents are needed Difficulties in preparation Risk of fouling and scaling Ion exchange adsorption–ultrafiltration Adsorptive ion exchange membrane Membrane distillation crystallization Leaching–flotation–precipitation process Membrane electrolysis MOF-based membrane Pervaporation The stepwise leaching–flotation–precipitation process was adopted to separate the Li/Fe/Mn from batteries [117]. First, the cathode material was leached according to the acid leaching procedure. Then, the Fe3+ cations are selectively floated and recovered as a FeCl3 in the flotation step. Finally, the Mn2+/Mn3+ and Li+ cations are precipitated and separated as MnO2/Mn2O3 and Li3PO4 using saturated KMnO4 solution and Na3PO4, respectively. As a result, the total recovery of Li, Fe, and Mn is ~81%, ~85%, and ~81%, respectively. Hence, that stepwise process could be considered an alternative way to separate and recover metals from spent Li-ion batteries effectively. 3.3.6. Membrane Electrolysis The membrane electrolysis was investigated to crystallize lithium carbonate from lithium-rich brines. The three-compartment reactor was applied. The brines were intro- duced in the middle compartment, separated from the anolyte and catholyte compartment outside. When a current is applied, anions and cations selectively migrate into the anionic and cathodic compartments, respectively. Water reduction increases the pH of the catholyte, which is recirculated in a crystallizer where CO2 is bubbled and converted to carbonate, precipitating Li2CO3 with a purity of at least 93.8 wt%. The method allows recovering as much as 90% of the lithium-containing solution volume as low salinity water, withPDF Image | Electro-Driven Materials and Processes for Lithium

PDF Search Title:

Electro-Driven Materials and Processes for LithiumOriginal File Name Searched:

membranes-12-00343-v3.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |