PDF Publication Title:

Text from PDF Page: 021

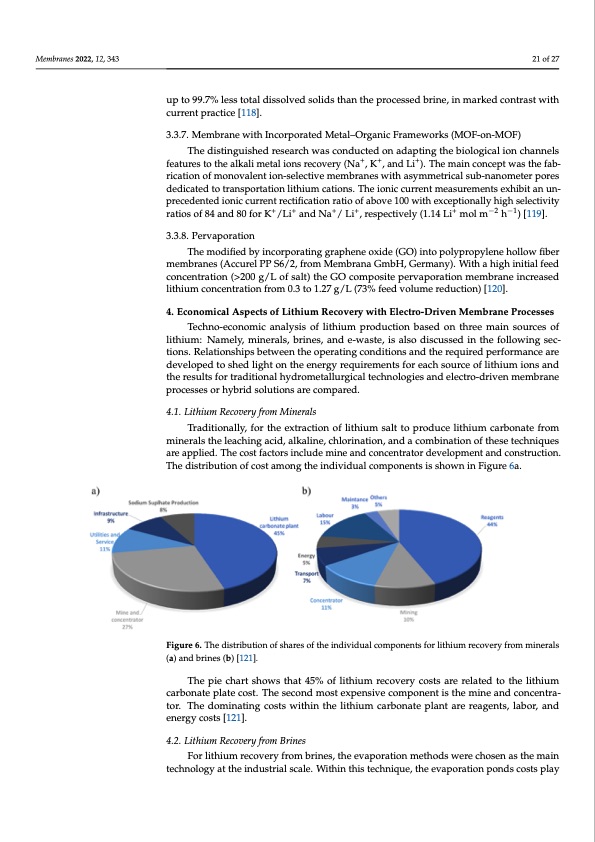

Membranes 2022, 12, 343 21 of 27 up to 99.7% less total dissolved solids than the processed brine, in marked contrast with current practice [118]. 3.3.7. Membrane with Incorporated Metal–Organic Frameworks (MOF-on-MOF) The distinguished research was conducted on adapting the biological ion channels features to the alkali metal ions recovery (Na+, K+, and Li+). The main concept was the fab- rication of monovalent ion-selective membranes with asymmetrical sub-nanometer pores dedicated to transportation lithium cations. The ionic current measurements exhibit an un- precedented ionic current rectification ratio of above 100 with exceptionally high selectivity ratios of 84 and 80 for K+/Li+ and Na+/ Li+, respectively (1.14 Li+ mol m−2 h−1) [119]. 3.3.8. Pervaporation The modified by incorporating graphene oxide (GO) into polypropylene hollow fiber membranes (Accurel PP S6/2, from Membrana GmbH, Germany). With a high initial feed concentration (>200 g/L of salt) the GO composite pervaporation membrane increased lithium concentration from 0.3 to 1.27 g/L (73% feed volume reduction) [120]. 4. Economical Aspects of Lithium Recovery with Electro-Driven Membrane Processes Techno-economic analysis of lithium production based on three main sources of lithium: Namely, minerals, brines, and e-waste, is also discussed in the following sec- tions. Relationships between the operating conditions and the required performance are developed to shed light on the energy requirements for each source of lithium ions and the results for traditional hydrometallurgical technologies and electro-driven membrane processes or hybrid solutions are compared. 4.1. Lithium Recovery from Minerals Traditionally, for the extraction of lithium salt to produce lithium carbonate from minerals the leaching acid, alkaline, chlorination, and a combination of these techniques Membranes 2022, 11, x FOR PEER REVIEW 20 of 27 are applied. The cost factors include mine and concentrator development and construction. The distribution of cost among the individual components is shown in Figure 6a. FigFuigreur6e.6T.Thheeddisisttrriibutionoffsshhaareressofotfhtehiendinivdiidvuidalucaolmcpoomnpenotnsefnortslifthoirulmithrieucomverreycofrvoemrymfirnoemralmsinerals (a) and brines (b). [121]. (a) and brines (b) [121]. The pie chart shows that 45% of lithium recovery costs are related to the lithium car- The pie chart shows that 45% of lithium recovery costs are related to the lithium bonate plate cost. The second most expensive component is the mine and concentrator. carbonate plate cost. The second most expensive component is the mine and concentra- The dominating costs within the lithium carbonate plant are reagents, labor, and energy tor. The dominating costs within the lithium carbonate plant are reagents, labor, and costs [121]. energy costs [121]. 4.2. Lithium Recovery from Brines 4.2. Lithium Recovery from Brines For lithium recovery from brines, the evaporation methods were chosen as the main For lithium recovery from brines, the evaporation methods were chosen as the main technology at the industrial scale. Within this technique, the evaporation ponds costs play technology at the industrial scale. Within this technique, the evaporation ponds costs play an important role. The second place takes lithium carbonate plate with its utilities and infrastructure (Figure 6b) [121]. From the operational cost, the reagents’ costs seem to be the most important part. Among them, sodium carbonate (28%), calcium oxide (12%), sodium hydroxide (7%), car- bon dioxide (4%), and hydrochloric acid (1%) should be mentioned [121]. 4.3. Lithium Recovery from e-Waste BrinesPDF Image | Electro-Driven Materials and Processes for Lithium

PDF Search Title:

Electro-Driven Materials and Processes for LithiumOriginal File Name Searched:

membranes-12-00343-v3.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |