PDF Publication Title:

Text from PDF Page: 014

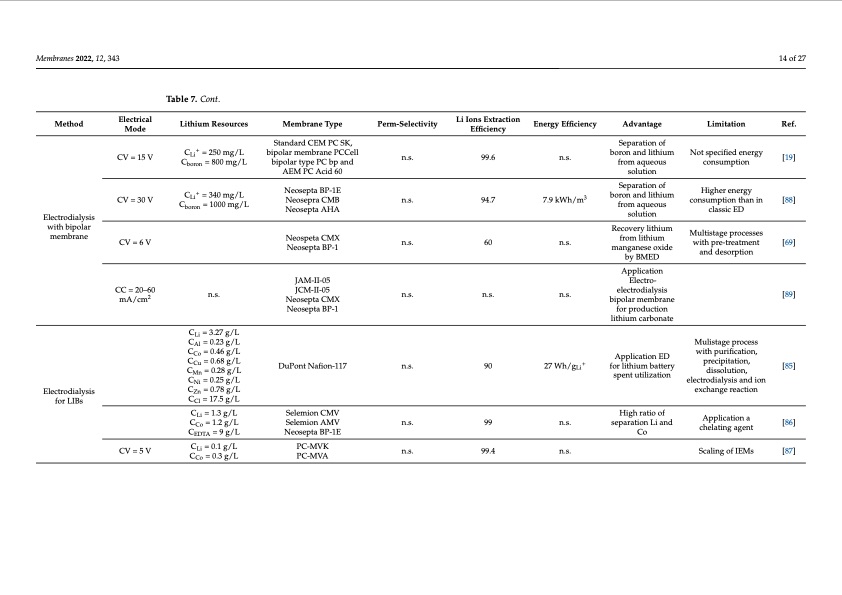

Membranes 2022, 12, 343 14 of 27 Ref. [19] [88] [69] [89] [85] [86] [87] Method Electrical Mode CV = 15 V CV = 30 V CV = 6 V CC = 20–60 mA/cm2 Table 7. Cont. Lithium Resources CLi+ = 250 mg/L Cboron = 800 mg/L Membrane Type Standard CEM PC SK, bipolar membrane PCCell bipolar type PC bp and AEM PC Acid 60 Neosepta BP-1E Neosepra CMB Neosepta AHA Neospeta CMX Neosepta BP-1 JAM-II-05 JCM-II-05 Neosepta CMX Neosepta BP-1 DuPont Nafion-117 Selemion CMV Selemion AMV Neosepta BP-1E PC-MVK PC-MVA Perm-Selectivity Li Ions Extraction Efficiency n.s. 99.6 n.s. 94.7 n.s. 60 n.s. n.s. n.s. 90 n.s. 99 n.s. 99.4 Energy Efficiency n.s. 7.9 kWh/m3 n.s. n.s. 27 Wh/gLi+ n.s. n.s. Advantage Separation of boron and lithium from aqueous solution Separation of boron and lithium from aqueous solution Recovery lithium from lithium manganese oxide by BMED Application Electro- electrodialysis bipolar membrane for production lithium carbonate Application ED for lithium battery spent utilization High ratio of separation Li and Co Limitation Not specified energy consumption Higher energy consumption than in classic ED Multistage processes with pre-treatment and desorption Mulistage process with purification, precipitation, dissolution, electrodialysis and ion exchange reaction Application a chelating agent Scaling of IEMs Electrodialysis with bipolar membrane + Cboron = 1000 mg/L n.s. CLi = 3.27 g/L CAl = 0.23 g/L CCo = 0.46 g/L CCu = 0.68 g/L CMn = 0.28 g/L CNi = 0.25 g/L CZn = 0.78 g/L CCl = 17.5 g/L CLi = 1.3 g/L CCo = 1.2 g/L CEDTA = 9 g/L CLi =0.1g/L CCo = 0.3 g/L CLi = 340 mg/L Electrodialysis for LIBs CV=5VPDF Image | Electro-Driven Materials and Processes for Lithium

PDF Search Title:

Electro-Driven Materials and Processes for LithiumOriginal File Name Searched:

membranes-12-00343-v3.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |