PDF Publication Title:

Text from PDF Page: 015

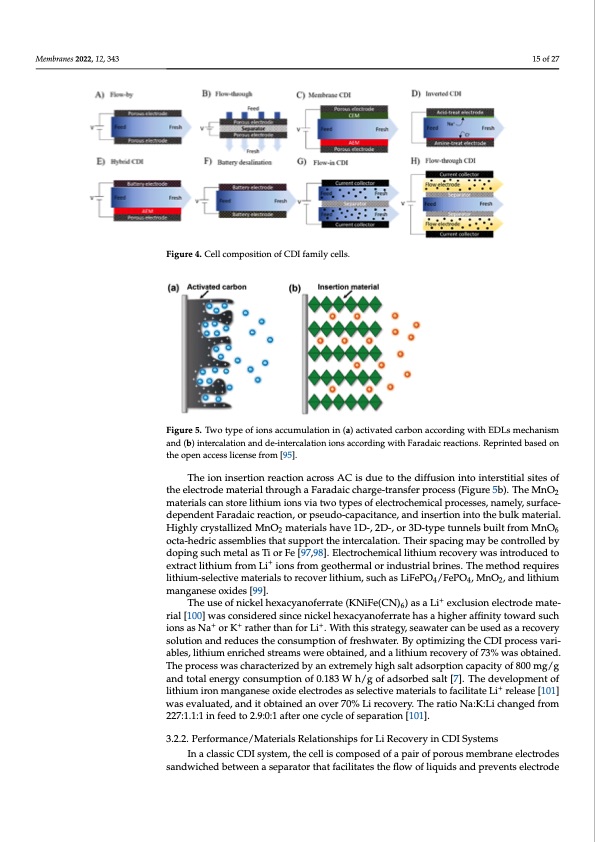

[90,92,94–96]. Typical CDI configurations are shown in Figure 4 Membranes 2022, 12, 343 3.2.1. Operation of CDI Systems Electro-active adsorbent materials, such as those used in CDI, mostly involve phy- sisorption at the solid–liquid interface to support ultra-selective extraction of resources [90,92,94–96]. Typical CDI configurations are shown in Figure 4 Figure 4. Cell composition of CDI family cells. The most popular material for CDI electrodes is activated carbon (AC) due to its low cost, high electrical conductivity, and large specific surface area. However, AC does not exhibit any selectivity toward ions due to the absence of selective sites (Figure 5a). To gFeinguereat4e. CLei+ll iconmpseolseitciotinvoitfyC,DthIefasmuirlyfaceellso.f activated carbon could be modified by selective Figure 4. Cell composition of CDI family cells. moieties such as α-MnO2 [96]. The most popular material for CDI electrodes is activated carbon (AC) due to its low cost, high electrical conductivity, and large specific surface area. However, AC does not exhibit any selectivity toward ions due to the absence of selective sites (Figure 5a). To generate Li+ ion selectivity, the surface of activated carbon could be modified by selective moieties such as α-MnO2 [96]. Figure 5. Two type of ions accumulation in (a) activated carbon according with EDLs mechanism Figure 5. Two type of ions accumulation in (a) activated carbon according with EDLs mechanism and (b) intercalation and de-intercalation ions according with Faradaic reactions. Reprinted based and (b) intercalation and de-intercalation ions according with Faradaic reactions. Reprinted based on octa-hedric assemblies that support the intercalation. Their spacing may be controlled by manganese oxides [99].. doping such metal as Ti or Fe [97,98]. Electrochemical lithium recovery was introduced to + The use of nickel hexacyanoffeerrraattee((KNiFiFee(C(CN)6)) )asasa aLiLiexecxlucsluiosnioenleecltercotdroedmeamteartiae-l extract lithium from Li+ ions from geothermal or industrial brines. The method requires r[i1a0l0[]1w00a]swcoasnsciodnesriederseindcseincicekneilchkexlahceyxaancoyfaenrroafteerrhaatse ahahsigahheirgahfefirnaitfyfintoitwyatrodwsaurcdhsiuocnhs lithium-selective materials to recover lithium, such as LiFePO4/FePO4, MnO2, and lithium +++ +++ iaosnsNasNoraKorrKatherartthhearnthfaonrfLoir.LWi .itWhitthisthsitsrastreagtye,gys,esaewaawteartecracnanbbeeuusseeddaassarecovery manganese oxides [99]. solution and reduces the consumption of freshwater. By optimizing the CDI process vari- The use of nickel hexacyanoferrate (KNiFe(CN)6) as a Li+ exclusion electrode material ables, lithium enriched streams were obtained, and a lithium recovery of 73% was obtained. [100] was considered since nickel hexacyanoferrate has a higher affinity toward such ions The process was characterized by an extremely high salt adsorption capacity of 800 mg/g as Na+ or K+ rather than for Li+. With this strategy, seawater can be used as a recovery and total energy consumption of 0.183 W h/g of adsorbed salt [7]. The development of lithium iron manganese oxide electrodes as selective materials to facilitate Li+ release [101] was evaluated, and it obtained an over 70% Li recovery. The ratio Na:K:Li changed from 227:1.1:1 in feed to 2.9:0:1 after one cycle of separation [101]. 3.2.2. Performance/Materials Relationships for Li Recovery in CDI Systems In a classic CDI system, the cell is composed of a pair of porous membrane electrodes sandwiched between a separator that facilitates the flow of liquids and prevents electrode 6 + 15 of 27 on the open access license from [95]. the open access license from [95]. The ion insertion reaction across AC is due to the diffusion into interstitial sites of the The ion insertion reaction across AC is due to the diffusion into interstitial sites of Figure 5. Two type of ions accumulation in (a) activated carbon according with EDLs mechanism electrode material through a Faradaic charge-transfer process (Figure 5b). The MnO2 ma- thanedel(ebc)tirnotedrecamlataiotenraianldtdher-oinutgerhcalaFtiaornaidoaniscachcoarrdgineg-trwainthsfFearapdraoiceresasc(tFioingsu.rRep5rbin).teTdhbeasMednO2 teorniathlse ocapnensatcocressliltihceinusme friomns[9v5i]a. two types of electrochemical processes, namely, surface- materials can store lithium ions via two types of electrochemical processes, namely, surface- dependent Faradaic reaction, or pseudo-capacitance, and insertion into the bulk material. dependent Faradaic reaction, or pseudo-capacitance, and insertion into the bulk material. The ion insertion reaction across AC is due to the diffusion into interstitial sites of the HighlycrystallizedMnO2 materialshave1D-,2D-,or3D-typettunnelsbuiillttffrromMnO6 26 electrode material through a Faradaic charge-transfer process (Figure 5b). The MnO2 ma- octa-hedric assemblies that support the intercalation.. Their spacing may be controlled by terials can store lithium ions via two types of electrochemical processes, namely, surface- doping such metal as Tii or Fe [97,98]. Electrochemical lithium recovery was introduced to dependent Faradaic rea+ction, or pseudo-capacitance, and insertion into the bulk material. extractlithiumfromLii+ ionsfromgeothermalorindustrialbrines.Themethodrequires Highly crystallized MnO2 materials have 1D-, 2D-, or 3D-type tunnels built from MnO6 lithiium--selleccttiiveemaatteerriaialslstotorreeccoovveerrliltihthiuiumm, ,susuchchasasLLiFieFPePOO/4/FePO4, MnO2, and lithium 442PDF Image | Electro-Driven Materials and Processes for Lithium

PDF Search Title:

Electro-Driven Materials and Processes for LithiumOriginal File Name Searched:

membranes-12-00343-v3.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |