PDF Publication Title:

Text from PDF Page: 149

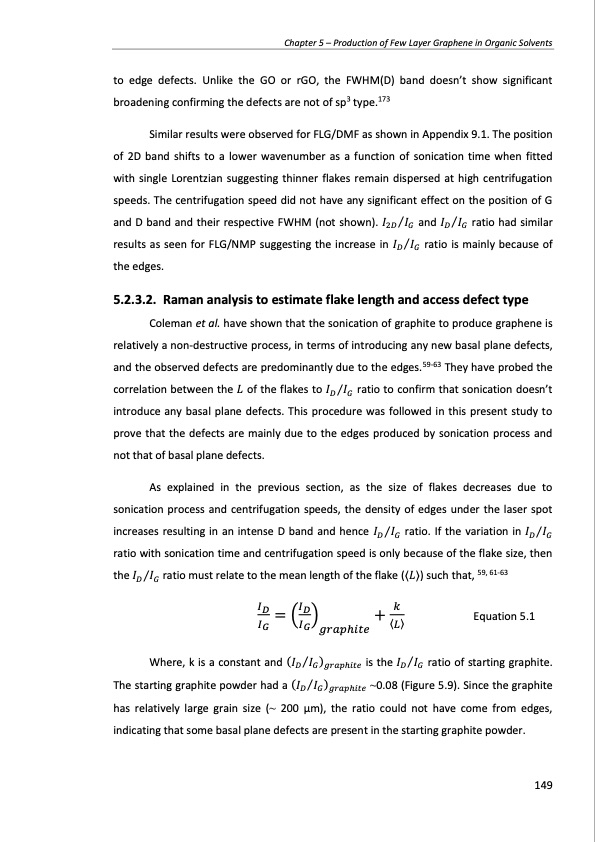

Chapter 5 – Production of Few Layer Graphene in Organic Solvents to edge defects. Unlike the GO or rGO, the FWHM(D) band doesn’t show significant broadening confirming the defects are not of sp3 type.173 Similar results were observed for FLG/DMF as shown in Appendix 9.1. The position of 2D band shifts to a lower wavenumber as a function of sonication time when fitted with single Lorentzian suggesting thinner flakes remain dispersed at high centrifugation speeds. The centrifugation speed did not have any significant effect on the position of G and D band and their respective FWHM (not shown). 𝐼2𝐷⁄𝐼𝐺 and 𝐼𝐷⁄𝐼𝐺 ratio had similar results as seen for FLG/NMP suggesting the increase in 𝐼𝐷⁄𝐼𝐺 ratio is mainly because of the edges. 5.2.3.2. Raman analysis to estimate flake length and access defect type Coleman et al. have shown that the sonication of graphite to produce graphene is relatively a non-destructive process, in terms of introducing any new basal plane defects, and the observed defects are predominantly due to the edges.59-63 They have probed the correlation between the 𝐿 of the flakes to 𝐼𝐷⁄𝐼𝐺 ratio to confirm that sonication doesn’t introduce any basal plane defects. This procedure was followed in this present study to prove that the defects are mainly due to the edges produced by sonication process and not that of basal plane defects. As explained in the previous section, as the size of flakes decreases due to sonication process and centrifugation speeds, the density of edges under the laser spot increases resulting in an intense D band and hence 𝐼𝐷⁄𝐼𝐺 ratio. If the variation in 𝐼𝐷⁄𝐼𝐺 ratio with sonication time and centrifugation speed is only because of the flake size, then the 𝐼𝐷⁄𝐼𝐺 ratio must relate to the mean length of the flake (〈𝐿〉) such that, 59, 61-63 𝐼𝐷 = (𝐼𝐷) + 𝑘 Equation 5.1 𝐼𝐺 𝐼𝐺 𝑔𝑟𝑎𝑝h𝑖𝑡𝑒 〈𝐿〉 Where, k is a constant and (𝐼𝐷⁄𝐼𝐺)𝑔𝑟𝑎𝑝h𝑖𝑡𝑒 is the 𝐼𝐷⁄𝐼𝐺 ratio of starting graphite. The starting graphite powder had a (𝐼𝐷⁄𝐼𝐺)𝑔𝑟𝑎𝑝h𝑖𝑡𝑒 ~0.08 (Figure 5.9). Since the graphite has relatively large grain size (~ 200 μm), the ratio could not have come from edges, indicating that some basal plane defects are present in the starting graphite powder. 149PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |