PDF Publication Title:

Text from PDF Page: 148

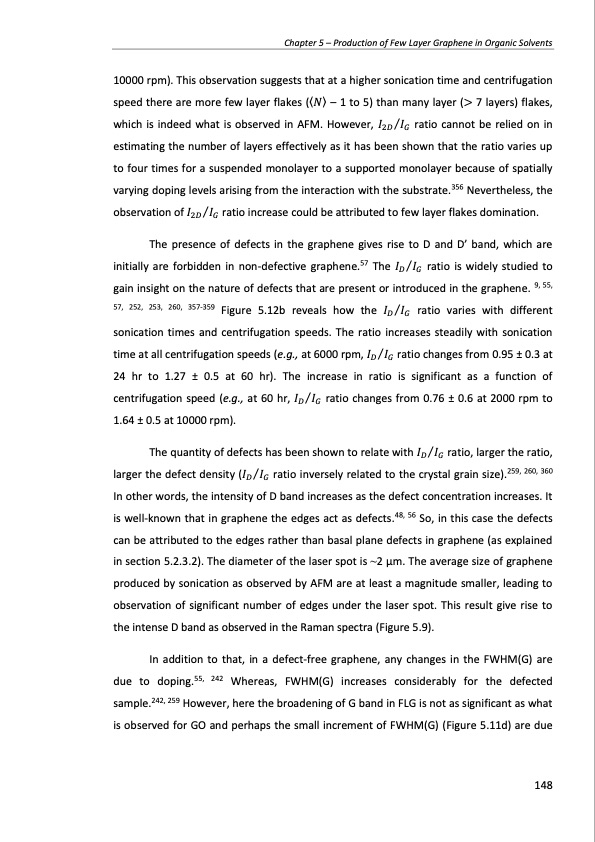

Chapter 5 – Production of Few Layer Graphene in Organic Solvents 10000 rpm). This observation suggests that at a higher sonication time and centrifugation speed there are more few layer flakes (〈𝑁〉 – 1 to 5) than many layer (> 7 layers) flakes, which is indeed what is observed in AFM. However, 𝐼2𝐷⁄𝐼𝐺 ratio cannot be relied on in estimating the number of layers effectively as it has been shown that the ratio varies up to four times for a suspended monolayer to a supported monolayer because of spatially varying doping levels arising from the interaction with the substrate.356 Nevertheless, the observation of 𝐼2𝐷⁄𝐼𝐺 ratio increase could be attributed to few layer flakes domination. The presence of defects in the graphene gives rise to D and D’ band, which are initially are forbidden in non-defective graphene.57 The 𝐼𝐷⁄𝐼𝐺 ratio is widely studied to gain insight on the nature of defects that are present or introduced in the graphene. 9, 55, 57, 252, 253, 260, 357-359 Figure 5.12b reveals how the 𝐼𝐷⁄𝐼𝐺 ratio varies with different sonication times and centrifugation speeds. The ratio increases steadily with sonication time at all centrifugation speeds (e.g., at 6000 rpm, 𝐼𝐷⁄𝐼𝐺 ratio changes from 0.95 ± 0.3 at 24 hr to 1.27 ± 0.5 at 60 hr). The increase in ratio is significant as a function of centrifugation speed (e.g., at 60 hr, 𝐼𝐷⁄𝐼𝐺 ratio changes from 0.76 ± 0.6 at 2000 rpm to 1.64 ± 0.5 at 10000 rpm). The quantity of defects has been shown to relate with 𝐼𝐷⁄𝐼𝐺 ratio, larger the ratio, larger the defect density (𝐼𝐷⁄𝐼𝐺 ratio inversely related to the crystal grain size).259, 260, 360 In other words, the intensity of D band increases as the defect concentration increases. It is well-known that in graphene the edges act as defects.48, 56 So, in this case the defects can be attributed to the edges rather than basal plane defects in graphene (as explained in section 5.2.3.2). The diameter of the laser spot is ~2 μm. The average size of graphene produced by sonication as observed by AFM are at least a magnitude smaller, leading to observation of significant number of edges under the laser spot. This result give rise to the intense D band as observed in the Raman spectra (Figure 5.9). In addition to that, in a defect-free graphene, any changes in the FWHM(G) are due to doping.55, 242 Whereas, FWHM(G) increases considerably for the defected sample.242, 259 However, here the broadening of G band in FLG is not as significant as what is observed for GO and perhaps the small increment of FWHM(G) (Figure 5.11d) are due 148PDF Image | PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITES

PDF Search Title:

PRODUCTION AND APPLICATIONS OF GRAPHENE AND ITS COMPOSITESOriginal File Name Searched:

graphene-production-applications.PDFDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Power up your energy storage game with Salgenx Salt Water Battery. With its advanced technology, the flow battery provides reliable, scalable, and sustainable energy storage for utility-scale projects. Upgrade to a Salgenx flow battery today and take control of your energy future.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |