PDF Publication Title:

Text from PDF Page: 002

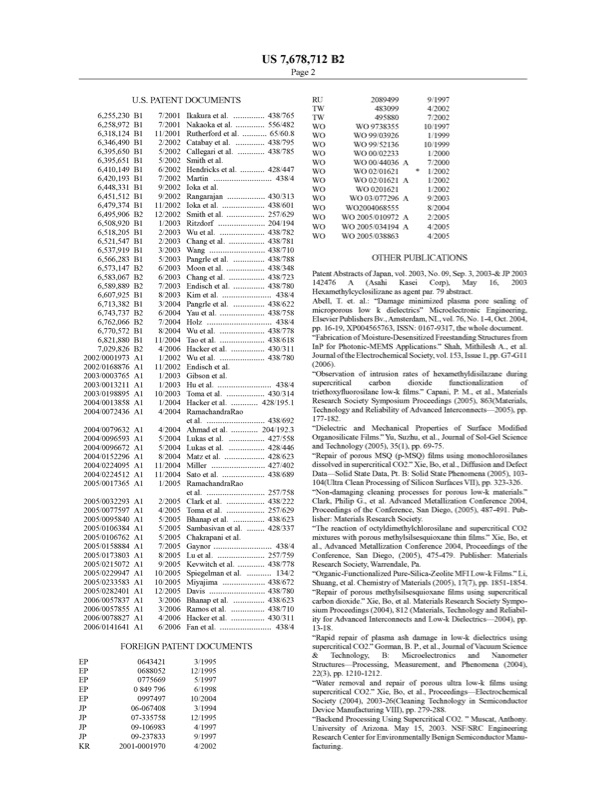

6.255.230 B1 6,258,972 B1 6,318,124 B1 6,346,490 B1 6,395,650 B1 6,395,651 B1 6.410,149 B1 6.420,193B1 6,448,331 B1 6,451,512 B1 6.479,374 B1 6,495,906B2 7/2001 Ikakuraetal. .438,765 7/2001 Nakaokaetal.. .556,482 11/2001 Rutherfordetal..65.60.8 2/2002 Catabayetal. . .438/795 5/2002 Callegarietal. . .438,785 5,2002 Smithetal. 6/2002 Hendricksetal..428.447 7/2002Martin ...438/4 9,2002 Iokaetal. 9/2002 Rangarajan .430,313 1,2002 Iokaetal.. ...438.601 12/2002Smithetal.. .257,629 TW WO WO WO WO WO WO WO WO WO WO WO2004O68555 WO WO2005.010972A 2006/0057837 A1 2006/0057855 A1 2006/0078827A1 2006,O141641 A1 3/2006 Bhanapetal. .438,623 3/2006 Ramosetal. .438,710 4/2006 Hackeretal.. .430/311 6/2006 Fan etal. . 438/4 EP EP EP EP EP JP JP JP JP KR O643421 O688052 O775669 O 849 796 O997497 06-067408 O7-335758 09-106983 O9-237833 2001-0001970 3,1995 12/1995 5,1997 6,1998 10,2004 3,1994 12/1995 4f1997 9,1997 4/2002 U.S.PATENTDOCUMENTS RU 2O89499 9,1997 TW 483099 4/2002 E.E.O.E."E WOWO20503194A4205 WO WO 2005/038863 4/2005 OTHER PUBLICATIONS PatentAbstractsofJapan,vol.2003,No.09,Sep.3,2003-&JP2003 6,521,547 B1 6,537,919 B1 6,566.283 B1 6,573,147B2 6,583,067B2 2/2003 Changetal. .438,781 3/2003 Wang . .438,710 5/2003 Pangrileetal. .438/788 6,2003 Moonetal.. ...438/348 6/2003 Changetal.. .438.723 6/2004Yauetal.. 7/2004 Holz.. 8,2004 Wu etal. . .438.758 . 438/4 438,778 .438,618 .430/311 1/2002Wuetal..438/780 11/2004Taoetal.. 4/2006 Hackeretal.. 11/2002 Endischetal. 1/2003 Gibsonetal. 1/2003 Huetal..438/4 10,2003 Tomaetal.., 430/314 1/2004 Hackeretal..428,1951 4/2004 RamachandraRao etal. . 4/2004 Ahmad etal. . .438,692 204/1923 5/2004 Lukasetal. .427,558 5/2004 Lukasetal. .428,446 8,2004 Matzetal.. .428,623 11/2004 Miller .427/402 11/2004 Satoetal..438,689 1/2005 RamachandraRao etal. .257/758 2/2005 Clarketal. .438,222 4/2005 Tomaetal. . .257,629 5/2005 Bhanapetal. .438,623 5/2005 Sambasivanetal. .428,337 5/2005 Chakrapanietal. 7/2005 Gaynor.438/4 8/2005 Luetal..257/759 9,2005 Kevwitchetal.. .438,778 10/2005 Spiegelmanetal. . 1342 10/2005Miyajima.438,672 2005/0233583Al 2005/0282401Al 12/2005Davis. 438/780 FOREIGN PATENT DOCUMENTS US7,678,712B2 Page2 6sosoB2 7/203Endichetal...438/7so 142476 A (Asahi Kasei Corp), May 16, 203 6,607.925B1 8/2003Kimetal..484 Hexamethylcyclosilizaneasagentpar.79abstract. 6,713,382B1 6,743,737B2 6,762,066 B2 6,770.572 B1 6,821,880B1 7,029,826 B2 2002/0001973A1 2002/0168876 A1 2003/OOO3765 A1 2003/0013211 A1 2003/0198895 A1 2004/0013858 A1 2004f0072436 A1 20040079632 A1 2004/0096.593 A1 2004/0096672 A1 2004/O152296 A1 2004/0224095 A1 2004/0224,512 Al 2005,OO17365 A1 2005/OO32293 A1 2005/OO77597 A1 2005/OO95840 A1 2005/0106384 A1 2005/0106762 A1 2005.O158884 A1 2005/01738O3 A1 2005/0215072 A1 2005/0229947 A1 3/2004Pangrileetal.. .438,622 Abell,T.etal.:"Damageminimizedplasmaporesealingof microporouslowkdielectrics'MicroelectronicEngineering, ElsevierPublishersBv.,Amsterdam,NL,vol.76,No.1-4,Oct.2004, pp. 16-19, XP004565763, ISSN: O167-9317, the whole document. “FabricationofMoisture-DesensitizedFreestandingStructuresfrom InPforPhotonic-MEMSApplications.”Shah,MithileshA.,etal. JournaloftheElectrochemicalSociety,vol.153,Isue1.pp.G7-G11 (2006). “Observation of intrusion rates of hexamethyldisilaZane during Supercritical carbon dioxide functionalization of triethoxyfluorosilanelow-kfilms.”Capani,P.M.,etal.,Materials Research Society Symposium Proceedings (2005), 863(Materials, TechnologyandReliabilityofAdvancedInterconnects—2005),pp. 177-182. “Dielectric and Mechanical Properties of Surface Modified OrganosilicateFilms.”Yu,Suzhu,etal.,JournalofSol-GelScience andTechnology(2005),35(1),pp.69-75. “RepairofporousMSQ (p-MSQ)filmsusingmonochlorosilanes dissolvedinSupercriticalCO2.”Xie,Bo,etal.,DiffusionandDefect Data-SolidStateData,Pt.B:SolidStatePhenomena(2005),103 104(UltraCleanProcessingofSiliconSurfacesVII),pp.323-326. "Non-damaging cleaning processes for porous low-k materials.” Clark, Philip G. et al. Advanced Metallization Conference 2004, ProceedingsoftheConference,SanDiego,(2005),487-491.Pub lisher:MaterialsResearchSociety. “ThereactionofoctyldimethylchlorosilaneandSupercriticalCO2 mixtureswithporousmethylsilsesquioxanethinfilms.”Xie,Bo,et al.,AdvancedMetallizationConference2004,Proceedingsofthe Conference, San Diego, (2005), 475-479. Publisher: Materials ResearchSociety,Warrendale,Pa. “Organic-FunctionalizedPure-Silica-ZeoliteMFILow-kFilms.”Li, Shuang,etal.ChemistryofMaterials(2005),17(7),pp.1851-1854. “RepairofporousmethylsilsesquioxanefilmsusingSupercritical carbondioxide.”Xie,Bo,etal.MaterialsResearchSocietySympo siumProceedings(2004),812(Materials,TechnologyandReliabil ityforAdvancedInterconnectsandLow-kDielectrics—2004),pp. 13-18. "Rapid repair of plasma ash damage in low-k dielectrics using SupercriticalCO2.”Gorman,B.P.etal.,JournalofVacuumScience & Technology, B: Microelectronics and Nanometer Structures—Processing. Measurement, and Phenomena (2004), 2(3),p.1210-1212. “Water removal and repair of porous ultra low-k films using SupercriticalCO2.”Xie,Bo,etal.,Proceedings—Electrochemical Society(2004),2003-26(CleaningTechnologyinSemiconductor DeviceManufacturingVI),p.279-288. “BackendProcessingUsingSupercriticalCO2.”Muscat,Anthony. University of Arizona. May 15, 2003. NSF/SRC Engineering ResearchCenterforEnvironmentallyBenignSemiconductorManu facturing. 49588O WO 9738355 WO99/03926 WO99,52136 WOOO?O2233 WOOOf44036 WO O2/O1621 T2002 10,1997 1,1999 10,1999 1,2000 A T2000 * 1?2OO2 1,2002 1,2002 9,2003 8,2004 2,2005 WOO2/O1621A WOO2O1621 WOO3,O77296 APDF Image | VAPOR PHASE TREATMENT OF DELECTRIC MATERALS

PDF Search Title:

VAPOR PHASE TREATMENT OF DELECTRIC MATERALSOriginal File Name Searched:

US7678712.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |