PDF Publication Title:

Text from PDF Page: 003

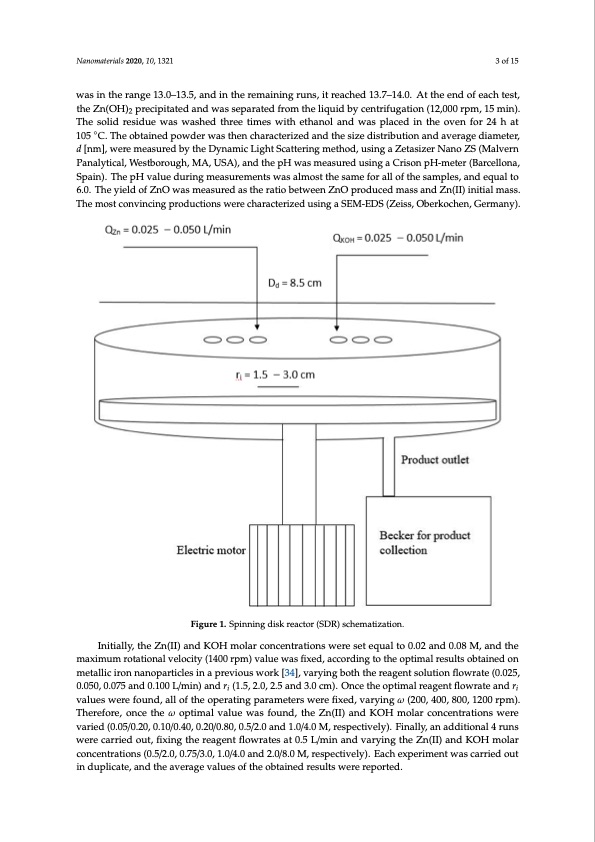

Nanomaterials 2020, 10, 1321 3 of 15 Nanomaterials 2020, 10, x FOR PEER REVIEW 3 of 15 The solid residue was washed three times with ethanol and was placed in the oven for 24 h at 105 °C. was in the range 13.0–13.5, and in the remaining runs, it reached 13.7–14.0. At the end of each test, The obtained powder was then characterized and the size distribution and average diameter, d [nm], the Zn(OH)2 precipitated and was separated from the liquid by centrifugation (12,000 rpm, 15 min). were measured by the Dynamic Light Scattering method, using a Zetasizer Nano ZS (Malvern The solid residue was washed three times with ethanol and was placed in the oven for 24 h at Panalytical, Westborough, MA, USA), and the pH was measured using a Crison pH-meter 105 ◦C. The obtained powder was then characterized and the size distribution and average diameter, (Barcellona, Spain). The pH value during measurements was almost the same for all of the samples, d [nm], were measured by the Dynamic Light Scattering method, using a Zetasizer Nano ZS (Malvern and equal to 6.0. The yield of ZnO was measured as the ratio between ZnO produced mass and Zn(II) Panalytical, Westborough, MA, USA), and the pH was measured using a Crison pH-meter (Barcellona, initial mass. The most convincing productions were characterized using a SEM-EDS (Zeiss, Spain). The pH value during measurements was almost the same for all of the samples, and equal to 6.0. The yield of ZnO was measured as the ratio between ZnO produced mass and Zn(II) initial mass. The most convincing productions were characterized using a SEM-EDS (Zeiss, Oberkochen, Germany). Figure 1. Spinning disk reactor (SDR) schematization. Figure 1. Spinning disk reactor (SDR) schematization. Initially, the Zn(II) and KOH molar concentrations were set equal to 0.02 and 0.08 M, and the Table 1. Experimental conditions adopted in the 25 runs. maximum rotational velocity (1400 rpm) value was fixed, according to the optimal results obtained on metallic iron naIDnopQarZtnic(lLe/sminina) pQreKvOiHou(Ls/wmoirnk) [3Z4n],(IvIa)r(yMin)g KboOthHth(Me r)eaωge(nrpt smo)lutrio(ncmfl)owrate (0.025, 0.050, 0.075 and10.100 L/m25in) and ri (1.52,52.0, 2.5 and03.0.02cm). On0c.e08the opti1m40a0l reage1n.t5flowrate and ri values were fou2nd, all o5f0the operatin5g0parameters0.w02ere fixed0,.v08arying ω14(0200, 4010.,5800, 1200 rpm). Therefore, once3the ω 1o0p0timal value1w00as found, 0th.0e2Zn(II) a0n.d08KOH m14o0l0ar con1c.e5ntrations were varied (0.05/0.204, 0.10/0.4205, 0.20/0.80, 0.255/2.0 and 1.00/4.0.02M, respe0c.0ti8vely). F1i4n0a0lly, an a2dditional 4 runs were carried ou5t, fixing5t0he reagent fl5o0wrates at 0.05.0L2/min and0.0v8arying 1th4e00Zn(II) 2and KOH molar concentrations (60.5/2.0, 100.705/3.0, 1.0/4.010a0nd 2.0/8.0 M0.,0r2espective0l.y0)8. Each e1x4p00eriment2was carried out in duplicate, an7d the ave2r5age values of2t5he obtained0.r0e2sults wer0e.0r8eported1.400 2.5 Oberkochen, Germany). 8 50 50 0.02 0.08 1400 2.5PDF Image | Spinning Disk Reactor Nano Production Intensification

PDF Search Title:

Spinning Disk Reactor Nano Production IntensificationOriginal File Name Searched:

nanomaterials-10-01321.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |