PDF Publication Title:

Text from PDF Page: 002

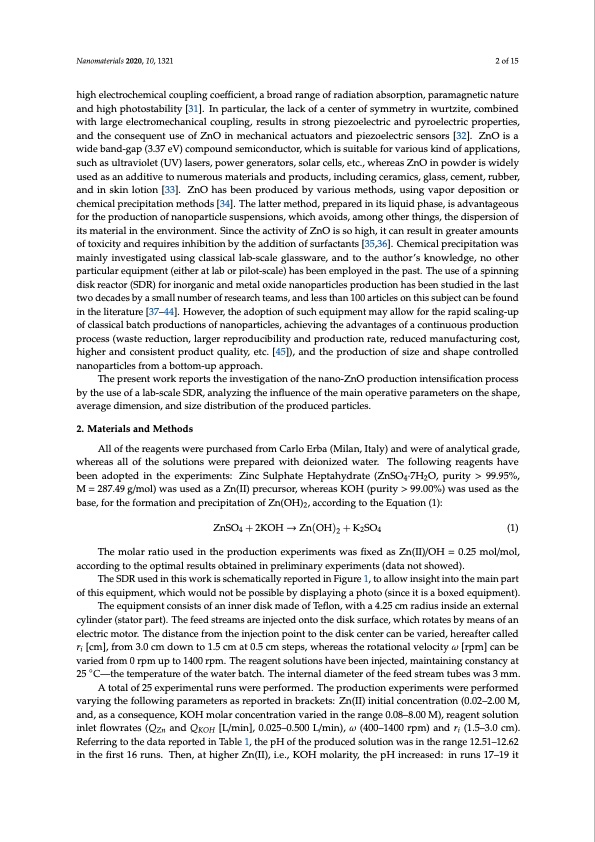

Nanomaterials 2020, 10, 1321 2 of 15 high electrochemical coupling coefficient, a broad range of radiation absorption, paramagnetic nature and high photostability [31]. In particular, the lack of a center of symmetry in wurtzite, combined with large electromechanical coupling, results in strong piezoelectric and pyroelectric properties, and the consequent use of ZnO in mechanical actuators and piezoelectric sensors [32]. ZnO is a wide band-gap (3.37 eV) compound semiconductor, which is suitable for various kind of applications, such as ultraviolet (UV) lasers, power generators, solar cells, etc., whereas ZnO in powder is widely used as an additive to numerous materials and products, including ceramics, glass, cement, rubber, and in skin lotion [33]. ZnO has been produced by various methods, using vapor deposition or chemical precipitation methods [34]. The latter method, prepared in its liquid phase, is advantageous for the production of nanoparticle suspensions, which avoids, among other things, the dispersion of its material in the environment. Since the activity of ZnO is so high, it can result in greater amounts of toxicity and requires inhibition by the addition of surfactants [35,36]. Chemical precipitation was mainly investigated using classical lab-scale glassware, and to the author’s knowledge, no other particular equipment (either at lab or pilot-scale) has been employed in the past. The use of a spinning disk reactor (SDR) for inorganic and metal oxide nanoparticles production has been studied in the last two decades by a small number of research teams, and less than 100 articles on this subject can be found in the literature [37–44]. However, the adoption of such equipment may allow for the rapid scaling-up of classical batch productions of nanoparticles, achieving the advantages of a continuous production process (waste reduction, larger reproducibility and production rate, reduced manufacturing cost, higher and consistent product quality, etc. [45]), and the production of size and shape controlled nanoparticles from a bottom-up approach. The present work reports the investigation of the nano-ZnO production intensification process by the use of a lab-scale SDR, analyzing the influence of the main operative parameters on the shape, average dimension, and size distribution of the produced particles. 2. Materials and Methods All of the reagents were purchased from Carlo Erba (Milan, Italy) and were of analytical grade, whereas all of the solutions were prepared with deionized water. The following reagents have been adopted in the experiments: Zinc Sulphate Heptahydrate (ZnSO4·7H2O, purity > 99.95%, M = 287.49 g/mol) was used as a Zn(II) precursor, whereas KOH (purity > 99.00%) was used as the base, for the formation and precipitation of Zn(OH)2, according to the Equation (1): ZnSO4 + 2KOH → Zn(OH)2 + K2SO4 (1) The molar ratio used in the production experiments was fixed as Zn(II)/OH = 0.25 mol/mol, according to the optimal results obtained in preliminary experiments (data not showed). The SDR used in this work is schematically reported in Figure 1, to allow insight into the main part of this equipment, which would not be possible by displaying a photo (since it is a boxed equipment). The equipment consists of an inner disk made of Teflon, with a 4.25 cm radius inside an external cylinder (stator part). The feed streams are injected onto the disk surface, which rotates by means of an electric motor. The distance from the injection point to the disk center can be varied, hereafter called ri [cm], from 3.0 cm down to 1.5 cm at 0.5 cm steps, whereas the rotational velocity ω [rpm] can be varied from 0 rpm up to 1400 rpm. The reagent solutions have been injected, maintaining constancy at 25 ◦C—the temperature of the water batch. The internal diameter of the feed stream tubes was 3 mm. A total of 25 experimental runs were performed. The production experiments were performed varying the following parameters as reported in brackets: Zn(II) initial concentration (0.02–2.00 M, and, as a consequence, KOH molar concentration varied in the range 0.08–8.00 M), reagent solution inlet flowrates (QZn and QKOH [L/min], 0.025–0.500 L/min), ω (400–1400 rpm) and ri (1.5–3.0 cm). Referring to the data reported in Table 1, the pH of the produced solution was in the range 12.51–12.62 in the first 16 runs. Then, at higher Zn(II), i.e., KOH molarity, the pH increased: in runs 17–19 itPDF Image | Spinning Disk Reactor Nano Production Intensification

PDF Search Title:

Spinning Disk Reactor Nano Production IntensificationOriginal File Name Searched:

nanomaterials-10-01321.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |