PDF Publication Title:

Text from PDF Page: 002

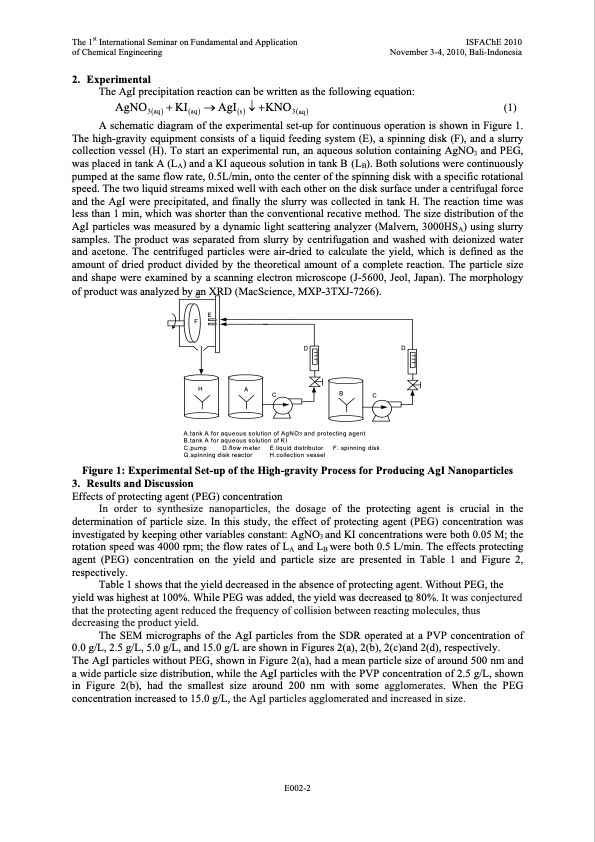

The 1st International Seminar on Fundamental and Application ISFAChE 2010 of Chemical Engineering November 3-4, 2010, Bali-Indonesia 2. Experimental The AgI precipitation reaction can be written as the following equation: AgNO3(aq) + KI(aq) → AgI(s) ↓ +KNO3(aq) (1) A schematic diagram of the experimental set-up for continuous operation is shown in Figure 1. The high-gravity equipment consists of a liquid feeding system (E), a spinning disk (F), and a slurry collection vessel (H). To start an experimental run, an aqueous solution containing AgNO3 and PEG, was placed in tank A (LA) and a KI aqueous solution in tank B (LB). Both solutions were continuously pumped at the same flow rate, 0.5L/min, onto the center of the spinning disk with a specific rotational speed. The two liquid streams mixed well with each other on the disk surface under a centrifugal force and the AgI were precipitated, and finally the slurry was collected in tank H. The reaction time was less than 1 min, which was shorter than the conventional recative method. The size distribution of the AgI particles was measured by a dynamic light scattering analyzer (Malvern, 3000HSA) using slurry samples. The product was separated from slurry by centrifugation and washed with deionized water and acetone. The centrifuged particles were air-dried to calculate the yield, which is defined as the amount of dried product divided by the theoretical amount of a complete reaction. The particle size and shape were examined by a scanning electron microscope (J-5600, Jeol, Japan). The morphology of product was analyzed by an XRD (MacScience, MXP-3TXJ-7266). G E F HA DD CBC A.tank A for aqueous solution of AgNO3 and protecting agent B.tank A for aqueous solution of KI C.pump D.flow meter E.liquid distributor F. spinning disk G.spinning disk reactor H.collection vessel Figure 1: Experimental Set-up of the High-gravity Process for Producing AgI Nanoparticles 3. ResultsandDiscussion Effects of protecting agent (PEG) concentration In order to synthesize nanoparticles, the dosage of the protecting agent is crucial in the determination of particle size. In this study, the effect of protecting agent (PEG) concentration was investigated by keeping other variables constant: AgNO3 and KI concentrations were both 0.05 M; the rotation speed was 4000 rpm; the flow rates of LA and LB were both 0.5 L/min. The effects protecting agent (PEG) concentration on the yield and particle size are presented in Table 1 and Figure 2, respectively. Table 1 shows that the yield decreased in the absence of protecting agent. Without PEG, the yield was highest at 100%. While PEG was added, the yield was decreased to 80%. It was conjectured that the protecting agent reduced the frequency of collision between reacting molecules, thus decreasing the product yield. The SEM micrographs of the AgI particles from the SDR operated at a PVP concentration of 0.0 g/L, 2.5 g/L, 5.0 g/L, and 15.0 g/L are shown in Figures 2(a), 2(b), 2(c)and 2(d), respectively. The AgI particles without PEG, shown in Figure 2(a), had a mean particle size of around 500 nm and a wide particle size distribution, while the AgI particles with the PVP concentration of 2.5 g/L, shown in Figure 2(b), had the smallest size around 200 nm with some agglomerates. When the PEG concentration increased to 15.0 g/L, the AgI particles agglomerated and increased in size. E002-2PDF Image | Silver Iodide Nanoparticles Using a Spinning Disk Reactor

PDF Search Title:

Silver Iodide Nanoparticles Using a Spinning Disk ReactorOriginal File Name Searched:

preparation-of-silver-iodide-nanoparticles-spinning-disk-reactor.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |