PDF Publication Title:

Text from PDF Page: 002

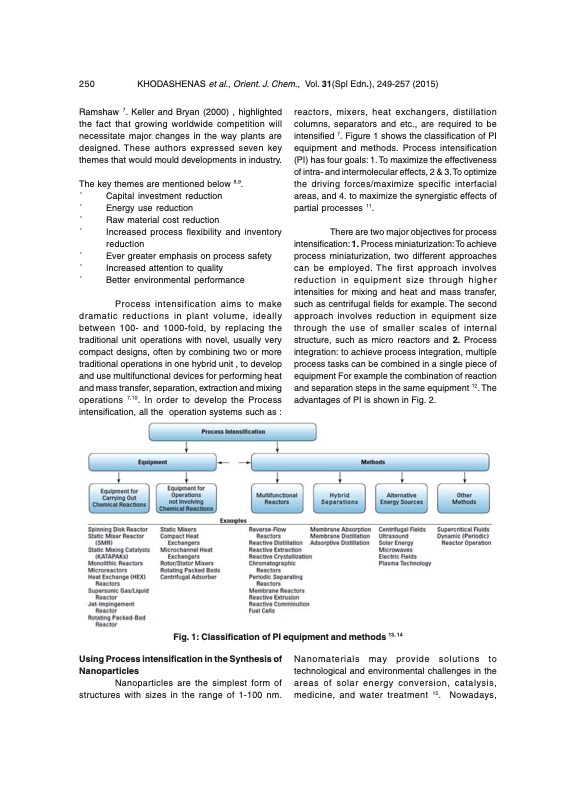

250 KHODASHENAS et al., Orient. J. Chem., Vol. 31(Spl Edn.), 249-257 (2015) Ramshaw 7. Keller and Bryan (2000) , highlighted the fact that growing worldwide competition will necessitate major changes in the way plants are designed. These authors expressed seven key themes that would mould developments in industry. The key themes are mentioned below 8,9. ́ Capital investment reduction ́ Energy use reduction ́ Raw material cost reduction ́ Increased process flexibility and inventory reduction ́ Ever greater emphasis on process safety ́ Increased attention to quality ́ Better environmental performance Process intensification aims to make dramatic reductions in plant volume, ideally between 100- and 1000-fold, by replacing the traditional unit operations with novel, usually very compact designs, often by combining two or more traditional operations in one hybrid unit , to develop and use multifunctional devices for performing heat and mass transfer, separation, extraction and mixing operations 7,10. In order to develop the Process intensification, all the operation systems such as : reactors, mixers, heat exchangers, distillation columns, separators and etc., are required to be intensified 7. Figure 1 shows the classification of PI equipment and methods. Process intensification (PI) has four goals: 1. To maximize the effectiveness of intra- and intermolecular effects, 2 & 3. To optimize the driving forces/maximize specific interfacial areas, and 4. to maximize the synergistic effects of partial processes 11. There are two major objectives for process intensification: 1. Process miniaturization: To achieve process miniaturization, two different approaches can be employed. The first approach involves reduction in equipment size through higher intensities for mixing and heat and mass transfer, such as centrifugal fields for example. The second approach involves reduction in equipment size through the use of smaller scales of internal structure, such as micro reactors and 2. Process integration: to achieve process integration, multiple process tasks can be combined in a single piece of equipment For example the combination of reaction and separation steps in the same equipment 12. The advantages of PI is shown in Fig. 2. Fig. 1: Classification of PI Using Process intensification in the Synthesis of Nanoparticles Nanoparticles are the simplest form of structures with sizes in the range of 1-100 nm. equipment and methods 13, 14 Nanomaterials may provide solutions to technological and environmental challenges in the areas of solar energy conversion, catalysis, medicine, and water treatment 15. Nowadays,PDF Image | Process Intensification for the Synthesis of Metal Nanoparticles

PDF Search Title:

Process Intensification for the Synthesis of Metal NanoparticlesOriginal File Name Searched:

sdr-synthesis-metal-nanoparticles.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |