PDF Publication Title:

Text from PDF Page: 004

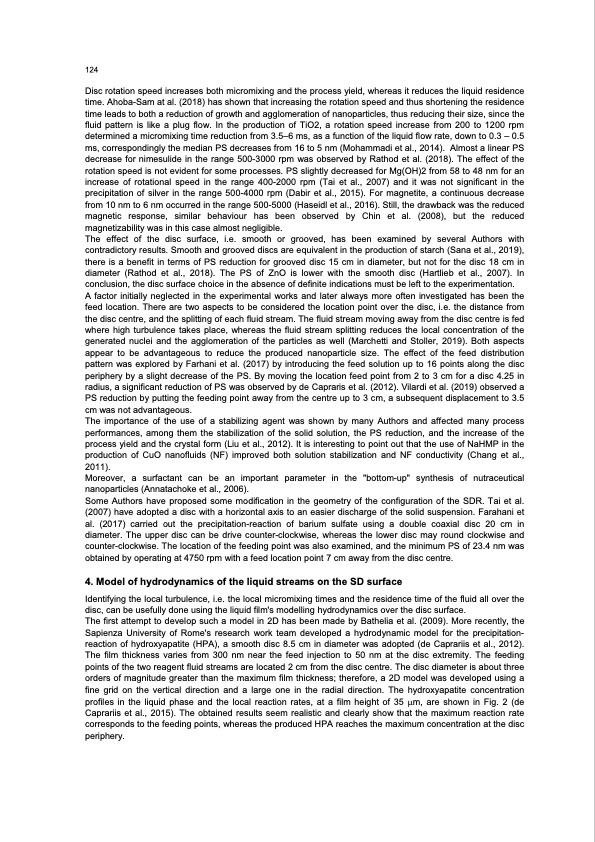

124 Disc rotation speed increases both micromixing and the process yield, whereas it reduces the liquid residence time. Ahoba-Sam at al. (2018) has shown that increasing the rotation speed and thus shortening the residence time leads to both a reduction of growth and agglomeration of nanoparticles, thus reducing their size, since the fluid pattern is like a plug flow. In the production of TiO2, a rotation speed increase from 200 to 1200 rpm determined a micromixing time reduction from 3.5–6 ms, as a function of the liquid flow rate, down to 0.3 – 0.5 ms, correspondingly the median PS decreases from 16 to 5 nm (Mohammadi et al., 2014). Almost a linear PS decrease for nimesulide in the range 500-3000 rpm was observed by Rathod et al. (2018). The effect of the rotation speed is not evident for some processes. PS slightly decreased for Mg(OH)2 from 58 to 48 nm for an increase of rotational speed in the range 400-2000 rpm (Tai et al., 2007) and it was not significant in the precipitation of silver in the range 500-4000 rpm (Dabir et al., 2015). For magnetite, a continuous decrease from 10 nm to 6 nm occurred in the range 500-5000 (Haseidl et al., 2016). Still, the drawback was the reduced magnetic response, similar behaviour has been observed by Chin et al. (2008), but the reduced magnetizability was in this case almost negligible. The effect of the disc surface, i.e. smooth or grooved, has been examined by several Authors with contradictory results. Smooth and grooved discs are equivalent in the production of starch (Sana et al., 2019), there is a benefit in terms of PS reduction for grooved disc 15 cm in diameter, but not for the disc 18 cm in diameter (Rathod et al., 2018). The PS of ZnO is lower with the smooth disc (Hartlieb et al., 2007). In conclusion, the disc surface choice in the absence of definite indications must be left to the experimentation. A factor initially neglected in the experimental works and later always more often investigated has been the feed location. There are two aspects to be considered the location point over the disc, i.e. the distance from the disc centre, and the splitting of each fluid stream. The fluid stream moving away from the disc centre is fed where high turbulence takes place, whereas the fluid stream splitting reduces the local concentration of the generated nuclei and the agglomeration of the particles as well (Marchetti and Stoller, 2019). Both aspects appear to be advantageous to reduce the produced nanoparticle size. The effect of the feed distribution pattern was explored by Farhani et al. (2017) by introducing the feed solution up to 16 points along the disc periphery by a slight decrease of the PS. By moving the location feed point from 2 to 3 cm for a disc 4.25 in radius, a significant reduction of PS was observed by de Capraris et al. (2012). Vilardi et al. (2019) observed a PS reduction by putting the feeding point away from the centre up to 3 cm, a subsequent displacement to 3.5 cm was not advantageous. The importance of the use of a stabilizing agent was shown by many Authors and affected many process performances, among them the stabilization of the solid solution, the PS reduction, and the increase of the process yield and the crystal form (Liu et al., 2012). It is interesting to point out that the use of NaHMP in the production of CuO nanofluids (NF) improved both solution stabilization and NF conductivity (Chang et al., 2011). Moreover, a surfactant can be an important parameter in the "bottom-up" synthesis of nutraceutical nanoparticles (Annatachoke et al., 2006). Some Authors have proposed some modification in the geometry of the configuration of the SDR. Tai et al. (2007) have adopted a disc with a horizontal axis to an easier discharge of the solid suspension. Farahani et al. (2017) carried out the precipitation-reaction of barium sulfate using a double coaxial disc 20 cm in diameter. The upper disc can be drive counter-clockwise, whereas the lower disc may round clockwise and counter-clockwise. The location of the feeding point was also examined, and the minimum PS of 23.4 nm was obtained by operating at 4750 rpm with a feed location point 7 cm away from the disc centre. 4. Model of hydrodynamics of the liquid streams on the SD surface Identifying the local turbulence, i.e. the local micromixing times and the residence time of the fluid all over the disc, can be usefully done using the liquid film's modelling hydrodynamics over the disc surface. The first attempt to develop such a model in 2D has been made by Bathelia et al. (2009). More recently, the Sapienza University of Rome's research work team developed a hydrodynamic model for the precipitation- reaction of hydroxyapatite (HPA), a smooth disc 8.5 cm in diameter was adopted (de Caprariis et al., 2012). The film thickness varies from 300 nm near the feed injection to 50 nm at the disc extremity. The feeding points of the two reagent fluid streams are located 2 cm from the disc centre. The disc diameter is about three orders of magnitude greater than the maximum film thickness; therefore, a 2D model was developed using a fine grid on the vertical direction and a large one in the radial direction. The hydroxyapatite concentration profiles in the liquid phase and the local reaction rates, at a film height of 35 m, are shown in Fig. 2 (de Caprariis et al., 2015). The obtained results seem realistic and clearly show that the maximum reaction rate corresponds to the feeding points, whereas the produced HPA reaches the maximum concentration at the disc periphery.PDF Image | Spinning Disc Reactor to produce Nanoparticles

PDF Search Title:

Spinning Disc Reactor to produce NanoparticlesOriginal File Name Searched:

sdr-nanoparticles.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |