PDF Publication Title:

Text from PDF Page: 002

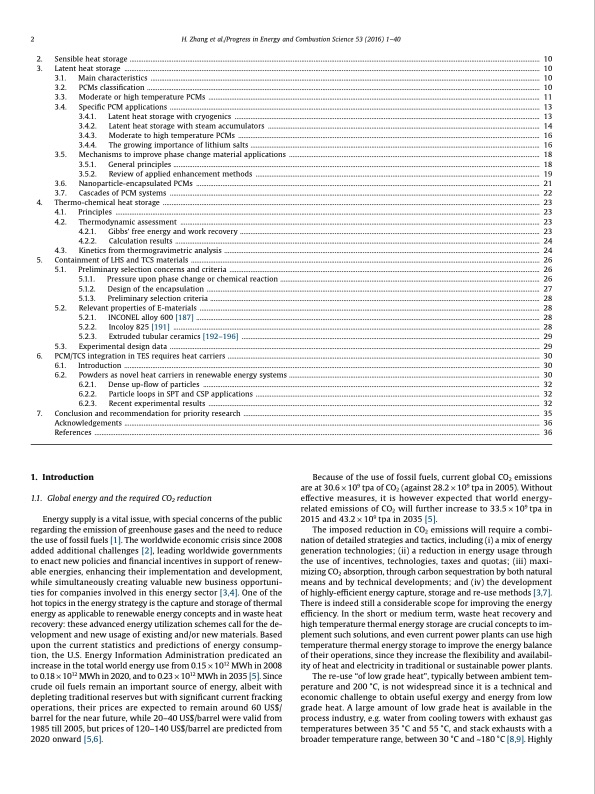

2 H. Zhang et al./Progress in Energy and Combustion Science 53 (2016) 1–40 2. 3. Sensible heat storage .......................................................................................................................................................................................................................................... 10 Latent heat storage ............................................................................................................................................................................................................................................. 10 3.1. Main characteristics .............................................................................................................................................................................................................................. 10 3.2. PCMs classification ................................................................................................................................................................................................................................ 10 3.3. Moderate or high temperature PCMs ............................................................................................................................................................................................. 11 3.4. Specific PCM applications ................................................................................................................................................................................................................... 13 3.4.1. Latent heat storage with cryogenics .............................................................................................................................................................................. 13 3.4.2. Latent heat storage with steam accumulators ........................................................................................................................................................... 14 3.4.3. Moderate to high temperature PCMs ............................................................................................................................................................................ 16 3.4.4. The growing importance of lithium salts ..................................................................................................................................................................... 16 3.5. Mechanisms to improve phase change material applications ............................................................................................................................................... 18 3.5.1. General principles ................................................................................................................................................................................................................. 18 3.5.2. Review of applied enhancement methods .................................................................................................................................................................. 19 3.6. Nanoparticle-encapsulated PCMs .................................................................................................................................................................................................... 21 3.7. Cascades of PCM systems ................................................................................................................................................................................................................... 22 Thermo-chemical heat storage ....................................................................................................................................................................................................................... 23 4.1. Principles .................................................................................................................................................................................................................................................. 23 4.2. Thermodynamic assessment ............................................................................................................................................................................................................. 23 4.2.1. Gibbs’ free energy and work recovery ........................................................................................................................................................................... 23 4.2.2. Calculation results ................................................................................................................................................................................................................ 24 4.3. Kinetics from thermogravimetric analysis .................................................................................................................................................................................... 24 Containment of LHS and TCS materials ....................................................................................................................................................................................................... 26 5.1. Preliminary selection concerns and criteria ................................................................................................................................................................................. 26 5.1.1. Pressure upon phase change or chemical reaction .................................................................................................................................................... 26 5.1.2. Design of the encapsulation .............................................................................................................................................................................................. 27 5.1.3. Preliminary selection criteria ............................................................................................................................................................................................ 28 5.2. Relevant properties of E-materials .................................................................................................................................................................................................. 28 5.2.1. INCONEL alloy 600 [187] .................................................................................................................................................................................................... 28 5.2.2. Incoloy 825 [191] ................................................................................................................................................................................................................. 28 5.2.3. Extruded tubular ceramics [192–196] .......................................................................................................................................................................... 29 5.3. Experimental design data ................................................................................................................................................................................................................... 29 PCM/TCS integration in TES requires heat carriers .................................................................................................................................................................................. 30 6.1. Introduction ............................................................................................................................................................................................................................................. 30 6.2. Powders as novel heat carriers in renewable energy systems ............................................................................................................................................... 30 6.2.1. Dense up-flow of particles ................................................................................................................................................................................................ 32 6.2.2. Particle loops in SPT and CSP applications .................................................................................................................................................................. 32 6.2.3. Recent experimental results ............................................................................................................................................................................................. 32 Conclusion and recommendation for priority research ......................................................................................................................................................................... 35 Acknowledgements ............................................................................................................................................................................................................................................. 36 References .............................................................................................................................................................................................................................................................. 36 4. 5. 6. 7. 1. Introduction 1.1. Global energy and the required CO2 reduction Energy supply is a vital issue, with special concerns of the public regarding the emission of greenhouse gases and the need to reduce the use of fossil fuels [1]. The worldwide economic crisis since 2008 added additional challenges [2], leading worldwide governments to enact new policies and financial incentives in support of renew- able energies, enhancing their implementation and development, while simultaneously creating valuable new business opportuni- ties for companies involved in this energy sector [3,4]. One of the hot topics in the energy strategy is the capture and storage of thermal energy as applicable to renewable energy concepts and in waste heat recovery: these advanced energy utilization schemes call for the de- velopment and new usage of existing and/or new materials. Based upon the current statistics and predictions of energy consump- tion, the U.S. Energy Information Administration predicated an increase in the total world energy use from 0.15 × 1012 MWh in 2008 to 0.18 × 1012 MWh in 2020, and to 0.23 × 1012 MWh in 2035 [5]. Since crude oil fuels remain an important source of energy, albeit with depleting traditional reserves but with significant current fracking operations, their prices are expected to remain around 60 US$/ barrel for the near future, while 20–40 US$/barrel were valid from 1985 till 2005, but prices of 120–140 US$/barrel are predicted from 2020 onward [5,6]. Because of the use of fossil fuels, current global CO2 emissions are at 30.6 × 109 tpa of CO2 (against 28.2 × 109 tpa in 2005). Without effective measures, it is however expected that world energy- related emissions of CO2 will further increase to 33.5 × 109 tpa in 2015 and 43.2 × 109 tpa in 2035 [5]. The imposed reduction in CO2 emissions will require a combi- nation of detailed strategies and tactics, including (i) a mix of energy generation technologies; (ii) a reduction in energy usage through the use of incentives, technologies, taxes and quotas; (iii) maxi- mizing CO2 absorption, through carbon sequestration by both natural means and by technical developments; and (iv) the development of highly-efficient energy capture, storage and re-use methods [3,7]. There is indeed still a considerable scope for improving the energy efficiency. In the short or medium term, waste heat recovery and high temperature thermal energy storage are crucial concepts to im- plement such solutions, and even current power plants can use high temperature thermal energy storage to improve the energy balance of their operations, since they increase the flexibility and availabil- ity of heat and electricity in traditional or sustainable power plants. The re-use “of low grade heat”, typically between ambient tem- perature and 200 °C, is not widespread since it is a technical and economic challenge to obtain useful exergy and energy from low grade heat. A large amount of low grade heat is available in the process industry, e.g. water from cooling towers with exhaust gas temperatures between 35 °C and 55 °C, and stack exhausts with a broader temperature range, between 30 °C and ~180 °C [8,9]. HighlyPDF Image | Thermal energy storage: Recent developments

PDF Search Title:

Thermal energy storage: Recent developmentsOriginal File Name Searched:

3-Thermal-Energy-storage-recent-developments-and-practical-aspects.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |