PDF Publication Title:

Text from PDF Page: 012

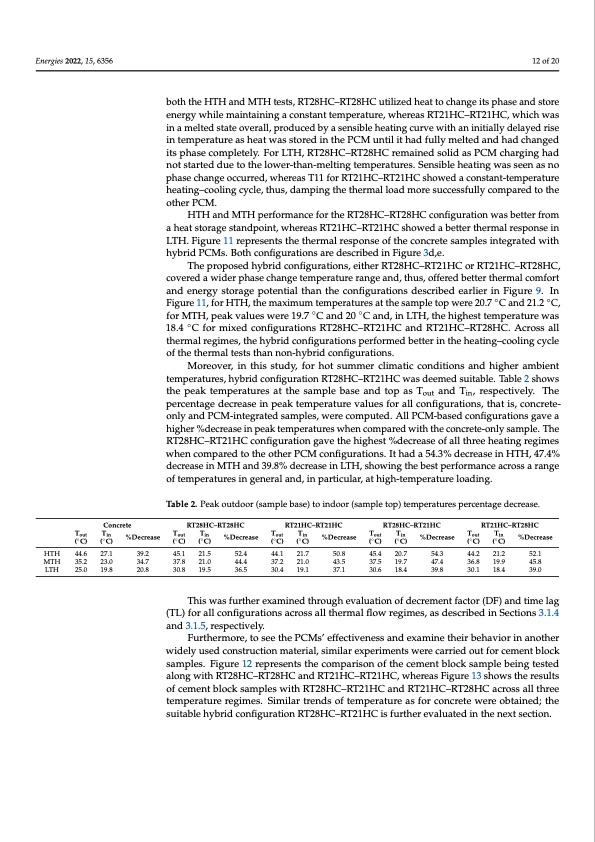

Energies 2022, 15, 6356 12 of 20 (◦C) (◦C) (◦C) (◦C) (◦C) (◦C) (◦C) (◦C) 45.4 20.7 54.3 (◦C) (◦C) 44.2 21.2 52.1 both the HTH and MTH tests, RT28HC–RT28HC utilized heat to change its phase and store energy while maintaining a constant temperature, whereas RT21HC–RT21HC, which was in a melted state overall, produced by a sensible heating curve with an initially delayed rise in temperature as heat was stored in the PCM until it had fully melted and had changed its phase completely. For LTH, RT28HC–RT28HC remained solid as PCM charging had not started due to the lower-than-melting temperatures. Sensible heating was seen as no phase change occurred, whereas T11 for RT21HC–RT21HC showed a constant-temperature heating–cooling cycle, thus, damping the thermal load more successfully compared to the other PCM. HTH and MTH performance for the RT28HC–RT28HC configuration was better from a heat storage standpoint, whereas RT21HC–RT21HC showed a better thermal response in LTH. Figure 11 represents the thermal response of the concrete samples integrated with hybrid PCMs. Both configurations are described in Figure 3d,e. The proposed hybrid configurations, either RT28HC–RT21HC or RT21HC–RT28HC, covered a wider phase change temperature range and, thus, offered better thermal comfort and energy storage potential than the configurations described earlier in Figure 9. In Figure 11, for HTH, the maximum temperatures at the sample top were 20.7 ◦C and 21.2 ◦C, for MTH, peak values were 19.7 ◦C and 20 ◦C and, in LTH, the highest temperature was 18.4 ◦C for mixed configurations RT28HC–RT21HC and RT21HC–RT28HC. Across all thermal regimes, the hybrid configurations performed better in the heating–cooling cycle of the thermal tests than non-hybrid configurations. Moreover, in this study, for hot summer climatic conditions and higher ambient temperatures, hybrid configuration RT28HC–RT21HC was deemed suitable. Table 2 shows the peak temperatures at the sample base and top as Tout and Tin, respectively. The percentage decrease in peak temperature values for all configurations, that is, concrete- only and PCM-integrated samples, were computed. All PCM-based configurations gave a higher %decrease in peak temperatures when compared with the concrete-only sample. The RT28HC–RT21HC configuration gave the highest %decrease of all three heating regimes when compared to the other PCM configurations. It had a 54.3% decrease in HTH, 47.4% decrease in MTH and 39.8% decrease in LTH, showing the best performance across a range of temperatures in general and, in particular, at high-temperature loading. Table 2. Peak outdoor (sample base) to indoor (sample top) temperatures percentage decrease. Concrete Tout Tin %Decrease RT28HC–RT28HC RT21HC–RT21HC Tout Tin %Decrease Tout Tin %Decrease RT28HC–RT21HC Tout Tin %Decrease RT21HC–RT28HC Tout Tin %Decrease HTH 44.6 27.1 39.2 MTH 35.2 23.0 34.7 LTH 25.0 19.8 20.8 45.1 21.5 52.4 44.1 21.7 50.8 37.8 21.0 44.4 37.2 21.0 43.5 30.8 19.5 36.5 30.4 19.1 37.1 37.5 19.7 47.4 30.6 18.4 39.8 36.8 19.9 45.8 30.1 18.4 39.0 This was further examined through evaluation of decrement factor (DF) and time lag (TL) for all configurations across all thermal flow regimes, as described in Sections 3.1.4 and 3.1.5, respectively. Furthermore, to see the PCMs’ effectiveness and examine their behavior in another widely used construction material, similar experiments were carried out for cement block samples. Figure 12 represents the comparison of the cement block sample being tested along with RT28HC–RT28HC and RT21HC–RT21HC, whereas Figure 13 shows the results of cement block samples with RT28HC–RT21HC and RT21HC–RT28HC across all three temperature regimes. Similar trends of temperature as for concrete were obtained; the suitable hybrid configuration RT28HC–RT21HC is further evaluated in the next section.PDF Image | PCM-Integrated Building Construction

PDF Search Title:

PCM-Integrated Building ConstructionOriginal File Name Searched:

energies-15-06356-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |