PDF Publication Title:

Text from PDF Page: 003

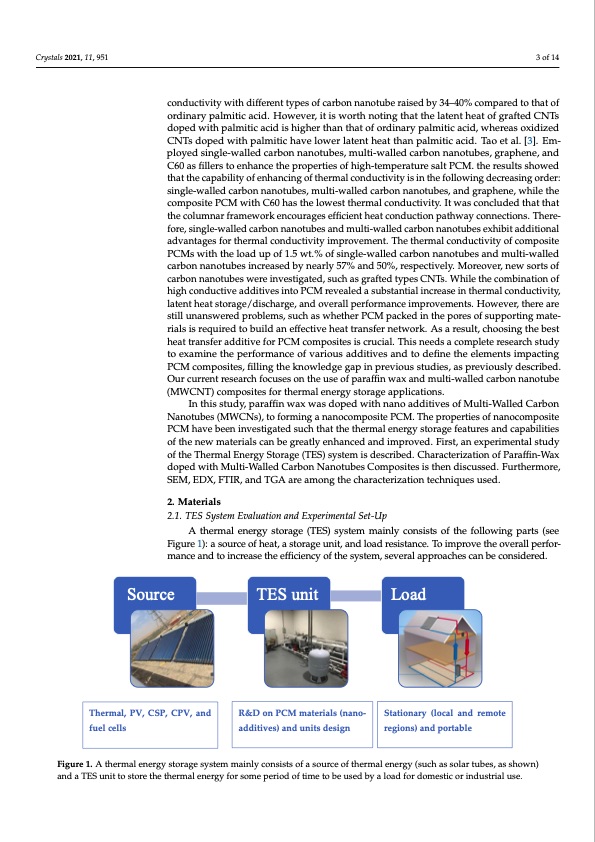

Crystals 2021, 11, 951 3 of 14 conductivity with different types of carbon nanotube raised by 34–40% compared to that of ordinary palmitic acid. However, it is worth noting that the latent heat of grafted CNTs doped with palmitic acid is higher than that of ordinary palmitic acid, whereas oxidized CNTs doped with palmitic have lower latent heat than palmitic acid. Tao et al. [3]. Em- ployed single-walled carbon nanotubes, multi-walled carbon nanotubes, graphene, and C60 as fillers to enhance the properties of high-temperature salt PCM. the results showed that the capability of enhancing of thermal conductivity is in the following decreasing order: single-walled carbon nanotubes, multi-walled carbon nanotubes, and graphene, while the composite PCM with C60 has the lowest thermal conductivity. It was concluded that that the columnar framework encourages efficient heat conduction pathway connections. There- fore, single-walled carbon nanotubes and multi-walled carbon nanotubes exhibit additional advantages for thermal conductivity improvement. The thermal conductivity of composite PCMs with the load up of 1.5 wt.% of single-walled carbon nanotubes and multi-walled carbon nanotubes increased by nearly 57% and 50%, respectively. Moreover, new sorts of carbon nanotubes were investigated, such as grafted types CNTs. While the combination of high conductive additives into PCM revealed a substantial increase in thermal conductivity, latent heat storage/discharge, and overall performance improvements. However, there are still unanswered problems, such as whether PCM packed in the pores of supporting mate- rials is required to build an effective heat transfer network. As a result, choosing the best heat transfer additive for PCM composites is crucial. This needs a complete research study to examine the performance of various additives and to define the elements impacting PCM composites, filling the knowledge gap in previous studies, as previously described. Our current research focuses on the use of paraffin wax and multi-walled carbon nanotube (MWCNT) composites for thermal energy storage applications. In this study, paraffin wax was doped with nano additives of Multi-Walled Carbon Nanotubes (MWCNs), to forming a nanocomposite PCM. The properties of nanocomposite PCM have been investigated such that the thermal energy storage features and capabilities of the new materials can be greatly enhanced and improved. First, an experimental study of the Thermal Energy Storage (TES) system is described. Characterization of Paraffin-Wax doped with Multi-Walled Carbon Nanotubes Composites is then discussed. Furthermore, SEM, EDX, FTIR, and TGA are among the characterization techniques used. 2. Materials 2.1. TES System Evaluation and Experimental Set-Up A thermal energy storage (TES) system mainly consists of the following parts (see Crystals 2021, 11, x FOR PEER REVIEW 4 of 15 Figure 1): a source of heat, a storage unit, and load resistance. To improve the overall perfor- mance and to increase the efficiency of the system, several approaches can be considered. Source TES unit Load Figure 1. A thermal energy storage system mainly consists of a source of thermal energy (such as solar tubes, as shown) Figure 1. A thermal energy storage system mainly consists of a source of thermal energy (such as solar tubes, as shown) R&D on PCM materials (nano- additives) and units design Stationary (local and remote regions) and portable Thermal, PV, CSP, CPV, and fuel cells and a TES unit to store the thermal energy for some period of time to be used by a load for domestic or industrial use. and a TES unit to store the thermal energy for some period of time to be used by a load for domestic or industrial use. The course of the melting and solidifying process of the PCM was investigated dur- ing the experiments. The material was tested as follows: Temperature sensors were in- stalled on the supply and return of the storage tank water system. The flow meter meas- ured the water flow continuously, and the measurement results were saved every 10 s. The mass of the material used to fill the bed, which was used during the test, was 822.3PDF Image | Paraffin Wax As a Phase Changing Material PCM

PDF Search Title:

Paraffin Wax As a Phase Changing Material PCMOriginal File Name Searched:

crystals-11-00951.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |