PDF Publication Title:

Text from PDF Page: 002

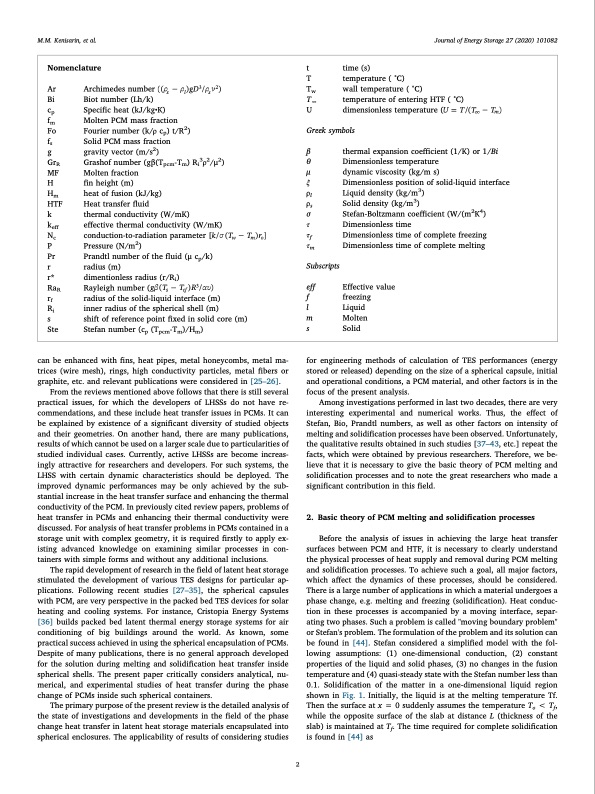

M.M. Kenisarin, et al. Journal of Energy Storage 27 (2020) 101082 Nomenclature Ar Archimedes number (( s Bi Biot number (Lh/k) cp Specific heat (kJ/kg•K) fm Molten PCM mass fraction Fo Fourier number (k/ρ cp) t/R ) fs Solid PCM mass fraction t time (s) T temperature ( °C) Tw wall temperature ( °C) T∞ temperature of entering HTF ( °C) U dimensionless temperature (U = T/(T Tm) Greek symbols β thermal expansion coefficient (1/K) or 1/Bi θ Dimensionless temperature μ dynamic viscosity (kg/m s) ξ Dimensionless position of solid-liquid interface ρl Liquid density (kg/m3) ρs Solid density (kg/m3) 2 4 σ Stefan-Boltzmann coefficient (W/(m K ) τ Dimensionless time τf Dimensionless time of complete freezing τm Dimensionless time of complete melting Subscripts eff Effective value f freezing l Liquid m Molten s Solid g gravity vector (m/s2) GrR Grashof number (gβ(Tpcm-Tm) Ri ρ /μ ) MF Molten fraction H fin height (m) Hm heat of fusion (kJ/kg) HTF Heat transfer fluid k thermal conductivity (W/mK) keff effective thermal conductivity (W/mK) Nc P Pr r r* Ra rf Ri s Ste 3 2 2 conduction-to-radiation parameter [k/ Pressure (N/m2) Prandtl number of the fluid (μ cp/k) radius (m) dimentionless radius (r/Ri) Rayleigh number (g (T T )R3/ ) (Tw Tm)ro] R scf radius of the solid-liquid interface (m) inner radius of the spherical shell (m) shift of reference point fixed in solid core (m) Stefan number (cp (Tpcm-Tm)/Hm) l)gD3/ s 2) 2 can be enhanced with fins, heat pipes, metal honeycombs, metal ma- trices (wire mesh), rings, high conductivity particles, metal fibers or graphite, etc. and relevant publications were considered in [25–26]. From the reviews mentioned above follows that there is still several practical issues, for which the developers of LHSSs do not have re- commendations, and these include heat transfer issues in PCMs. It can be explained by existence of a significant diversity of studied objects and their geometries. On another hand, there are many publications, results of which cannot be used on a larger scale due to particularities of studied individual cases. Currently, active LHSSs are become increas- ingly attractive for researchers and developers. For such systems, the LHSS with certain dynamic characteristics should be deployed. The improved dynamic performances may be only achieved by the sub- stantial increase in the heat transfer surface and enhancing the thermal conductivity of the PCM. In previously cited review papers, problems of heat transfer in PCMs and enhancing their thermal conductivity were discussed. For analysis of heat transfer problems in PCMs contained in a storage unit with complex geometry, it is required firstly to apply ex- isting advanced knowledge on examining similar processes in con- tainers with simple forms and without any additional inclusions. The rapid development of research in the field of latent heat storage stimulated the development of various TES designs for particular ap- plications. Following recent studies [27–35], the spherical capsules with PCM, are very perspective in the packed bed TES devices for solar heating and cooling systems. For instance, Cristopia Energy Systems [36] builds packed bed latent thermal energy storage systems for air conditioning of big buildings around the world. As known, some practical success achieved in using the spherical encapsulation of PCMs. Despite of many publications, there is no general approach developed for the solution during melting and solidification heat transfer inside spherical shells. The present paper critically considers analytical, nu- merical, and experimental studies of heat transfer during the phase change of PCMs inside such spherical containers. The primary purpose of the present review is the detailed analysis of the state of investigations and developments in the field of the phase change heat transfer in latent heat storage materials encapsulated into spherical enclosures. The applicability of results of considering studies for engineering methods of calculation of TES performances (energy stored or released) depending on the size of a spherical capsule, initial and operational conditions, a PCM material, and other factors is in the focus of the present analysis. Among investigations performed in last two decades, there are very interesting experimental and numerical works. Thus, the effect of Stefan, Bio, Prandtl numbers, as well as other factors on intensity of melting and solidification processes have been observed. Unfortunately, the qualitative results obtained in such studies [37–43, etc.] repeat the facts, which were obtained by previous researchers. Therefore, we be- lieve that it is necessary to give the basic theory of PCM melting and solidification processes and to note the great researchers who made a significant contribution in this field. 2. Basic theory of PCM melting and solidification processes Before the analysis of issues in achieving the large heat transfer surfaces between PCM and HTF, it is necessary to clearly understand the physical processes of heat supply and removal during PCM melting and solidification processes. To achieve such a goal, all major factors, which affect the dynamics of these processes, should be considered. There is a large number of applications in which a material undergoes a phase change, e.g. melting and freezing (solidification). Heat conduc- tion in these processes is accompanied by a moving interface, separ- ating two phases. Such a problem is called "moving boundary problem" or Stefan's problem. The formulation of the problem and its solution can be found in [44]. Stefan considered a simplified model with the fol- lowing assumptions: (1) one-dimensional conduction, (2) constant properties of the liquid and solid phases, (3) no changes in the fusion temperature and (4) quasi-steady state with the Stefan number less than 0.1. Solidification of the matter in a one-dimensional liquid region shown in Fig. 1. Initially, the liquid is at the melting temperature Tf. Then the surface at x = 0 suddenly assumes the temperature To < Tf, while the opposite surface of the slab at distance L (thickness of the slab) is maintained at Tf. The time required for complete solidification is found in [44] as 2PDF Image | Journal of Energy Storage 27

PDF Search Title:

Journal of Energy Storage 27Original File Name Searched:

tes-spherical-ball-storage-paraffin.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |