PDF Publication Title:

Text from PDF Page: 003

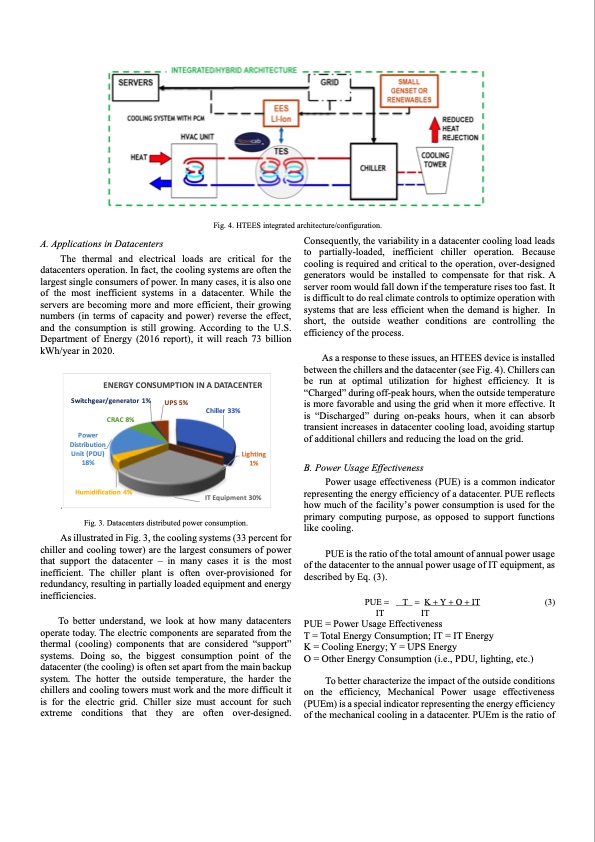

A. Applications in Datacenters The thermal and electrical loads are critical for the datacenters operation. In fact, the cooling systems are often the largest single consumers of power. In many cases, it is also one of the most inefficient systems in a datacenter. While the servers are becoming more and more efficient, their growing numbers (in terms of capacity and power) reverse the effect, and the consumption is still growing. According to the U.S. Department of Energy (2016 report), it will reach 73 billion kWh/year in 2020. . Fig. 3. Datacenters distributed power consumption. As illustrated in Fig. 3, the cooling systems (33 percent for chiller and cooling tower) are the largest consumers of power that support the datacenter – in many cases it is the most inefficient. The chiller plant is often over-provisioned for redundancy, resulting in partially loaded equipment and energy inefficiencies. To better understand, we look at how many datacenters operate today. The electric components are separated from the thermal (cooling) components that are considered “support” systems. Doing so, the biggest consumption point of the datacenter (the cooling) is often set apart from the main backup system. The hotter the outside temperature, the harder the chillers and cooling towers must work and the more difficult it is for the electric grid. Chiller size must account for such extreme conditions that they are often over-designed. Consequently, the variability in a datacenter cooling load leads to partially-loaded, inefficient chiller operation. Because cooling is required and critical to the operation, over-designed generators would be installed to compensate for that risk. A server room would fall down if the temperature rises too fast. It is difficult to do real climate controls to optimize operation with systems that are less efficient when the demand is higher. In short, the outside weather conditions are controlling the efficiency of the process. As a response to these issues, an HTEES device is installed between the chillers and the datacenter (see Fig. 4). Chillers can be run at optimal utilization for highest efficiency. It is “Charged” during off-peak hours, when the outside temperature is more favorable and using the grid when it more effective. It is “Discharged” during on-peaks hours, when it can absorb transient increases in datacenter cooling load, avoiding startup of additional chillers and reducing the load on the grid. B. Power Usage Effectiveness Power usage effectiveness (PUE) is a common indicator representing the energy efficiency of a datacenter. PUE reflects how much of the facility’s power consumption is used for the primary computing purpose, as opposed to support functions like cooling. PUE is the ratio of the total amount of annual power usage of the datacenter to the annual power usage of IT equipment, as described by Eq. (3). Fig. 4. HTEES integrated architecture/configuration. ENERGY CONSUMPTION IN A DATACENTER Switchgear/generator 1% CRAC 8% Humidification 4% UPS 5% Power Distribution Unit (PDU) 18% Chiller 33% IT Equipment 30% Lighting 1% PU PUE = Power Usage Effectiveness T = Total Energy Consumption; IT = IT Energy K = Cooling Energy; Y = UPS Energy O = Other Energy Consumption (i.e., PDU, lighting, etc.) To better characterize the impact of the outside conditions on the efficiency, Mechanical Power usage effectiveness (PUEm) is a special indicator representing the energy efficiency of the mechanical cooling in a datacenter. PUEm is the ratio ofPDF Image | Hybrid Thermal and Electric and Energy Storage System

PDF Search Title:

Hybrid Thermal and Electric and Energy Storage SystemOriginal File Name Searched:

2017_EESAT_Proceeding_Bilodeau.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |