PDF Publication Title:

Text from PDF Page: 003

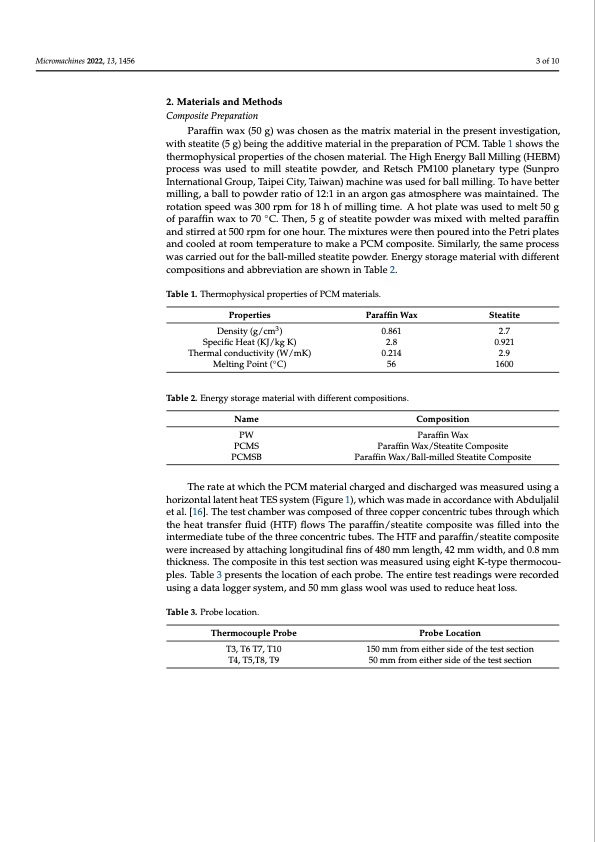

Micromachines 2022, 13, 1456 3 of 10 2. Materials and Methods Composite Preparation Paraffin wax (50 g) was chosen as the matrix material in the present investigation, with steatite (5 g) being the additive material in the preparation of PCM. Table 1 shows the thermophysical properties of the chosen material. The High Energy Ball Milling (HEBM) process was used to mill steatite powder, and Retsch PM100 planetary type (Sunpro International Group, Taipei City, Taiwan) machine was used for ball milling. To have better milling, a ball to powder ratio of 12:1 in an argon gas atmosphere was maintained. The rotation speed was 300 rpm for 18 h of milling time. A hot plate was used to melt 50 g of paraffin wax to 70 ◦C. Then, 5 g of steatite powder was mixed with melted paraffin and stirred at 500 rpm for one hour. The mixtures were then poured into the Petri plates and cooled at room temperature to make a PCM composite. Similarly, the same process was carried out for the ball-milled steatite powder. Energy storage material with different compositions and abbreviation are shown in Table 2. Table 1. Thermophysical properties of PCM materials. Properties Density (g/cm3) Specific Heat (KJ/kg K) Thermal conductivity (W/mK) Melting Point (◦C) Paraffin Wax Steatite 0.861 2.7 2.8 0.921 0.214 2.9 56 1600 Table 2. Energy storage material with different compositions. Name Composition PW PCMS PCMSB Paraffin Wax Paraffin Wax/Steatite Composite Paraffin Wax/Ball-milled Steatite Composite The rate at which the PCM material charged and discharged was measured using a horizontal latent heat TES system (Figure 1), which was made in accordance with Abduljalil et al. [16]. The test chamber was composed of three copper concentric tubes through which the heat transfer fluid (HTF) flows The paraffin/steatite composite was filled into the intermediate tube of the three concentric tubes. The HTF and paraffin/steatite composite were increased by attaching longitudinal fins of 480 mm length, 42 mm width, and 0.8 mm thickness. The composite in this test section was measured using eight K-type thermocou- ples. Table 3 presents the location of each probe. The entire test readings were recorded using a data logger system, and 50 mm glass wool was used to reduce heat loss. Table 3. Probe location. Thermocouple Probe T3, T6 T7, T10 T4, T5,T8, T9 Probe Location 150 mm from either side of the test section 50 mm from either side of the test sectionPDF Image | Heat Charging–Discharging Periods of Paraffin Wax

PDF Search Title:

Heat Charging–Discharging Periods of Paraffin WaxOriginal File Name Searched:

micromachines-13-01456-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |