PDF Publication Title:

Text from PDF Page: 005

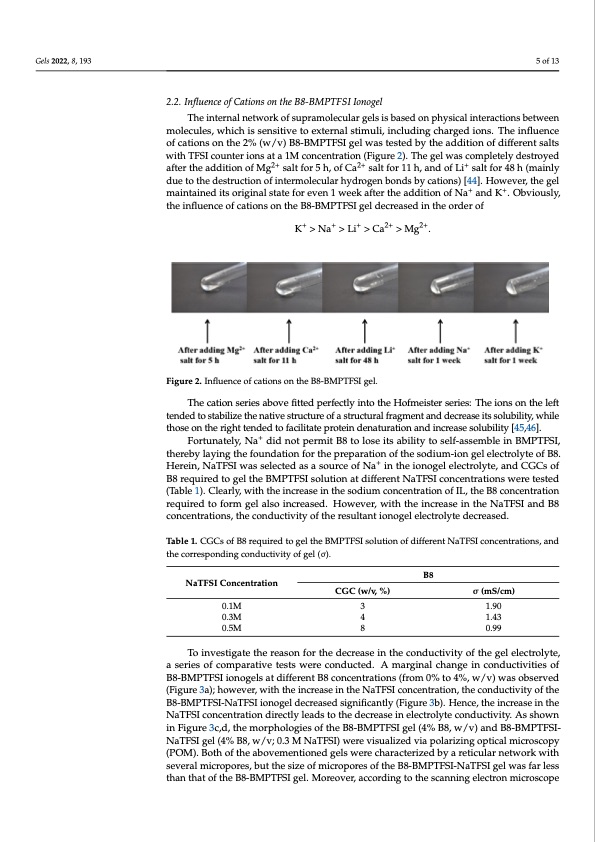

Gels 2022, 8, 193 5 of 13 2.2. Influence of Cations on the B8-BMPTFSI Ionogel The internal network of supramolecular gels is based on physical interactions between molecules, which is sensitive to external stimuli, including charged ions. The influence of cations on the 2% (w/v) B8-BMPTFSI gel was tested by the addition of different salts with TFSI counter ions at a 1M concentration (Figure 2). The gel was completely destroyed after the addition of Mg2+ salt for 5 h, of Ca2+ salt for 11 h, and of Li+ salt for 48 h (mainly due to the destruction of intermolecular hydrogen bonds by cations) [44]. However, the gel maintained its original state for even 1 week after the addition of Na+ and K+. Obviously, the influence of cations on the B8-BMPTFSI gel decreased in the order of Gels2022,8,xFORPEERREVIEW K+ >Na+ >Li+ >Ca2+ >Mg2+. 6 o Figure 2. Influence of cations on the B8-BMPTFSI gel. Figure 2. Influence of cations on the B8-BMPTFSI gel. The cation series above fitted perfectly into the Hofmeister series: The ions on the left Table 1. CGCs of B8 required to gel the BMPTFSI solution of different NaTFSI concentrations, tended to stabilize the native structure of a structural fragment and decrease its solubility, while the corresponding conductivity of gel (σ). those on the right tended to facilitate protein denaturation and increase solubility [45,46]. + B8 Fortunately, Na did not permit B8 to lose its ability to self-assemble in BMPTFSI, series of comparative tests were conducted. A marginal change in conductivities of NaTFSI concentration CGC (w/v, %) σ (mS/cm) thereby laying the foundation for the preparation of the sodium-ion gel electrolyte of B8. Herein, NaTFSI was selec0te.1dMas a source of Na+ in the3ionogel electrolyte, and CG1C.9s0of B8 required to gel the BM0P.3TMFSI solution at different N4aTFSI concentrations were t1e.s4t3ed (Table 1). Clearly, with the0i.n5cMrease in the sodium concen8tration of IL, the B8 concentr0a.9ti9on required to form gel also increased. However, with the increase in the NaTFSI and B8 concentrations, the cToondinuvcetsivtiigtyateofththeereraesounltafonrttihoenodgecerleealseectirnotlhyetecodnedcruecatsiveidty. of the gel electrolyt Table 1. CGCs ofBM8 rPeTquFSirIeidontogelsthaet dBMiffPerTeFnStIBs8olcuotinocnenotfrdaitfifoenresn(tfrNomaTF0%SI tcon4c%en, wtra/vti)ownsa,sanobdserved ( ure 3a); however, with the increase in the NaTFSI concentration, the conductivity of the corresponding conductivity of gel (σ). B8-BMPTFSI-NaTFSI ionogel decreased significantly (Figure 3b). Hence, the increas NaTFSI Concentration CGC (w/v, %) σ (mS/cm) the NaTFSI concentration directly leads to the decrease in electrolyte conductivity. shown in Figure 3c,d, the morphologies of the B8-BMPTFSI gel (4% B8, w/v) and B8 BMPTFSI-NaTFSI gel (4% B8, w/v; 0.3 M NaTFSI) were visualized via polarizing opt 0.1M 3 1.90 microscopy (POM). Both of the abovementioned gels were characterized by a retic 0.3M 4 1.43 network with several micropores, but the size of micropores of the B8-BMPTFSI-NaT 0.5M 8 0.99 gel was far less than that of the B8-BMPTFSI gel. Moreover, according to the scann electron microscope (SEM) images of xerogels (Figure S3), the abovementioned gels w To investigate the reason for the decrease in the conductivity of the gel electrolyte, also characterized by a reticular network, and the micropores of the xerogel of a series of comparative tests were conducted. A marginal change in conductivities of BMPTFSI-NaTFSI gel were smaller than those of the B8-BMPTFSI gel. Smaller micropo B8-BMPTFSI ionogels at different B8 concentrations (from 0% to 4%, w/v) was observed were not favorable for ion movement, leading to the decrease in conductivity [47]. In c (Figure 3a); however, with the increase in the NaTFSI concentration, the conductivity of the clusion, the addition of NaTFSI leads to a denser microstructure than the original gel [ B8-BMPTFSI-NaTFSI ionogel decreased significantly (Figure 3b). Hence, the increase in the leading to the decreased conductivity of the gel electrolyte. NaTFSI concentration directly leads to the decrease in electrolyte conductivity. As shown in Figure 3c,d, the morphologies of the B8-BMPTFSI gel (4% B8, w/v) and B8-BMPTFSI- NaTFSI gel (4% B8, w/v; 0.3 M NaTFSI) were visualized via polarizing optical microscopy (POM). Both of the abovementioned gels were characterized by a reticular network with several micropores, but the size of micropores of the B8-BMPTFSI-NaTFSI gel was far less than that of the B8-BMPTFSI gel. Moreover, according to the scanning electron microscope f a e B F e B i u i B o 4PDF Image | Thixotropic Ionogel Electrolyte for Sodium Batteries

PDF Search Title:

Thixotropic Ionogel Electrolyte for Sodium BatteriesOriginal File Name Searched:

gels-08-00193-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |