PDF Publication Title:

Text from PDF Page: 010

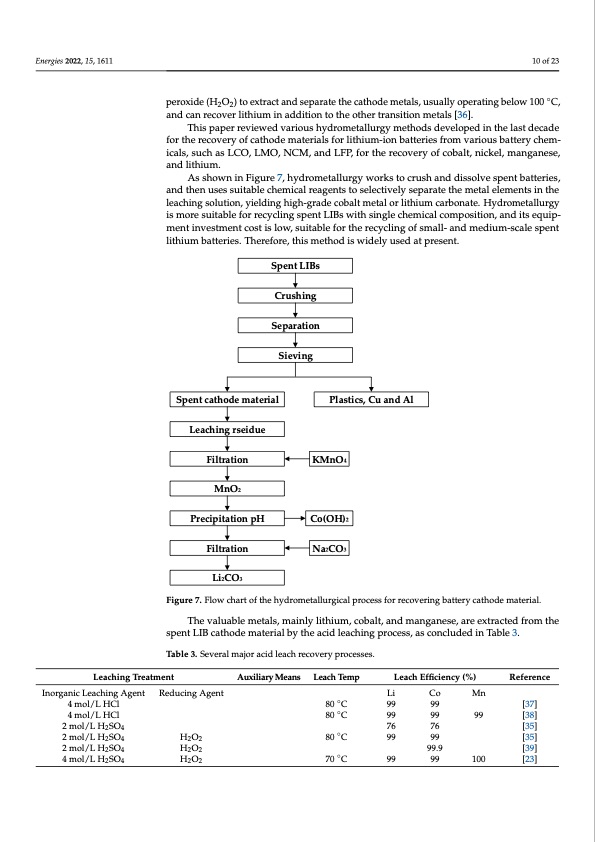

Energies 2022, 14, x FOR PEER REVIEW 11 of 24 Energies 2022, 15, 1611 4. Hydrometallurgy The hydrometallurgy process uses reagents such as hydrochloric acid (HCl), nitric acid (HNO3), sulfuric acid (H2SO4), phosphoric acid (H3PO4), organic acids, and hydrogen peroxide (H2O2) to extract and separate the cathode metals, usually operating below 100 °C, and can recover lithium in addition to the other transition metals [36]. ◦ peroxide(H2O2)toextractandseparatethecathodemetals,usuallyoperatingbelow100 C, 10 of 23 This paper reviewed various hydrometallurgy methods developed in the last decade and can recover lithium in addition to the other transition metals [36]. for the recovery of cathode materials for lithium-ion batteries from various battery This paper reviewed various hydrometallurgy methods developed in the last decade chemicals, such as LCO, LMO, NCM, and LFP, for the recovery of cobalt, nickel, for the recovery of cathode materials for lithium-ion batteries from various battery chem- manganese, and lithium. icals, such as LCO, LMO, NCM, and LFP, for the recovery of cobalt, nickel, manganese, As shown in Figure 7, hydrometallurgy works to crush and dissolve spent batteries, and lithium. and then uses suitable chemical reagents to selectively separate the metal elements in the As shown in Figure 7, hydrometallurgy works to crush and dissolve spent batteries, leaching solution, yielding high-grade cobalt metal or lithium carbonate. and then uses suitable chemical reagents to selectively separate the metal elements in the Hydrometallurgy is more suitable for recycling spent LIBs with single chemical leaching solution, yielding high-grade cobalt metal or lithium carbonate. Hydrometallurgy composition, and its equipment investment cost is low, suitable for the recycling of small- is more suitable for recycling spent LIBs with single chemical composition, and its equip- and medium-scale spent lithium batteries. Therefore, this method is widely used at ment investment cost is low, suitable for the recycling of small- and medium-scale spent present. lithium batteries. Therefore, this method is widely used at present. Leaching Treatment Auxiliary Means Leach Temp Leach Efficiency (%) Reference 4 mol/L HCl 80 80 99 99 99 99 76 99 99.9 99 99 99 [37] [37] Leaching Treatment Auxiliary Means Leach Temp Leach Efficiency (%) Co Mn Reference 4mol/LHCl 99 76 99 99 99 100 4 mol/L HCl C 80 ◦C 70 ◦C 80 °C [38] 99 [38] 4 mol/L HCl 2 mol/L H2SO4 2 mol/L H2SO4 2 mol/L H2SO4 4 mol/L H2SO4 H2O2 H2O2 H2O2 [35] [35] [39] [23] Leaching rseidue Spent LIBs Crushing Separation Sieving Spent cathode material Plastics, Cu and Al Filtration KMnO4 MnO2 Precipitation pH Co(OH)2 Filtration Na2CO3 Li2CO3 FFiigguurree77..Fllowcchaarrttoofftthheehhyydrroomeetatallulurrggicicaallpprroocceesssfoforrrereccoovveerirninggbbaatteteryrycacaththooddeemmaateteriraial.l. The valuable metals, mainly lithium, cobalt, and manganese, are extracted from the The valuable metals, mainly lithium, cobalt, and manganese, are extracted from the spent LIB cathode material by the acid leaching process, as concluded in Table 3. spent LIB cathode material by the acid leaching process, as concluded in Table 3. Table 3. Several major acid leach recovery processes. Table 3. Several major acid leach recovery processes. Inorganic Leaching Agent Reducing Agent Li C 99 Inorganic Leaching Agent Reducing Agent ◦ ◦ 80°C Li Co MnPDF Image | Recycling of Lithium Batteries

PDF Search Title:

Recycling of Lithium BatteriesOriginal File Name Searched:

energies-15-01611.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |