PDF Publication Title:

Text from PDF Page: 015

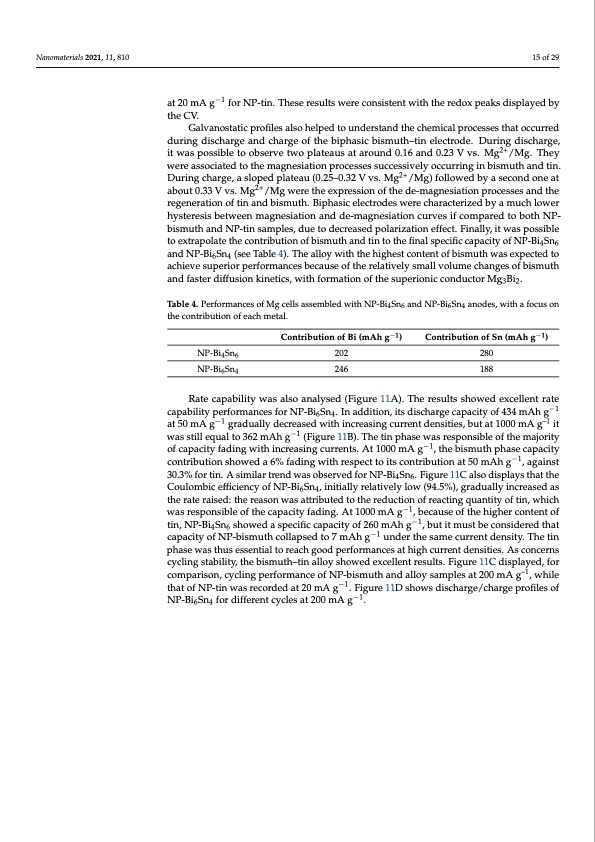

Nanomaterials 2021, 11, 810 15 of 29 at 20 mA g−1 for NP-tin. These results were consistent with the redox peaks displayed by the CV. Galvanostatic profiles also helped to understand the chemical processes that occurred during discharge and charge of the biphasic bismuth–tin electrode. During discharge, it was possible to observe two plateaus at around 0.16 and 0.23 V vs. Mg2+/Mg. They were associated to the magnesiation processes successively occurring in bismuth and tin. During charge, a sloped plateau (0.25–0.32 V vs. Mg2+/Mg) followed by a second one at about 0.33 V vs. Mg2+/Mg were the expression of the de-magnesiation processes and the regeneration of tin and bismuth. Biphasic electrodes were characterized by a much lower hysteresis between magnesiation and de-magnesiation curves if compared to both NP- bismuth and NP-tin samples, due to decreased polarization effect. Finally, it was possible to extrapolate the contribution of bismuth and tin to the final specific capacity of NP-Bi4Sn6 and NP-Bi6Sn4 (see Table 4). The alloy with the highest content of bismuth was expected to achieve superior performances because of the relatively small volume changes of bismuth and faster diffusion kinetics, with formation of the superionic conductor Mg3Bi2. Table 4. Performances of Mg cells assembled with NP-Bi4Sn6 and NP-Bi6Sn4 anodes, with a focus on the contribution of each metal. Contribution of Bi (mAh g−1) NP-Bi4 Sn6 202 NP-Bi6 Sn4 246 Contribution of Sn (mAh g−1) 280 188 Rate capability was also analysed (Figure 11A). The results showed excellent rate capability performances for NP-Bi6Sn4. In addition, its discharge capacity of 434 mAh g−1 at 50 mA g−1 gradually decreased with increasing current densities, but at 1000 mA g–1 it was still equal to 362 mAh g−1 (Figure 11B). The tin phase was responsible of the majority of capacity fading with increasing currents. At 1000 mA g−1, the bismuth phase capacity contribution showed a 6% fading with respect to its contribution at 50 mAh g−1, against 30.3% for tin. A similar trend was observed for NP-Bi4Sn6. Figure 11C also displays that the Coulombic efficiency of NP-Bi6Sn4, initially relatively low (94.5%), gradually increased as the rate raised: the reason was attributed to the reduction of reacting quantity of tin, which was responsible of the capacity fading. At 1000 mA g−1, because of the higher content of tin, NP-Bi4Sn6 showed a specific capacity of 260 mAh g−1, but it must be considered that capacity of NP-bismuth collapsed to 7 mAh g−1 under the same current density. The tin phase was thus essential to reach good performances at high current densities. As concerns cycling stability, the bismuth–tin alloy showed excellent results. Figure 11C displayed, for comparison, cycling performance of NP-bismuth and alloy samples at 200 mA g–1, while that of NP-tin was recorded at 20 mA g−1. Figure 11D shows discharge/charge profiles of NP-Bi6Sn4 for different cycles at 200 mA g−1.PDF Image | Overview on Anodes for Magnesium Batteries

PDF Search Title:

Overview on Anodes for Magnesium BatteriesOriginal File Name Searched:

nanomaterials-11-00810.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |