PDF Publication Title:

Text from PDF Page: 009

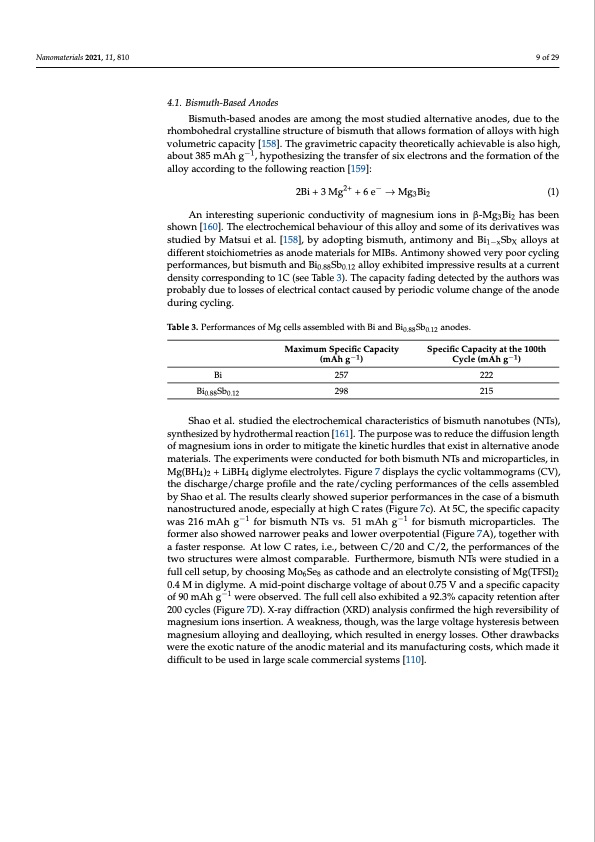

Nanomaterials 2021, 11, 810 9 of 29 4.1. Bismuth-Based Anodes Bismuth-based anodes are among the most studied alternative anodes, due to the rhombohedral crystalline structure of bismuth that allows formation of alloys with high volumetric capacity [158]. The gravimetric capacity theoretically achievable is also high, about 385 mAh g−1, hypothesizing the transfer of six electrons and the formation of the alloy according to the following reaction [159]: 2Bi+3Mg2+ +6e− →Mg3Bi2 (1) An interesting superionic conductivity of magnesium ions in β-Mg3Bi2 has been shown [160]. The electrochemical behaviour of this alloy and some of its derivatives was studied by Matsui et al. [158], by adopting bismuth, antimony and Bi1−xSbX alloys at different stoichiometries as anode materials for MIBs. Antimony showed very poor cycling performances, but bismuth and Bi0.88Sb0.12 alloy exhibited impressive results at a current density corresponding to 1C (see Table 3). The capacity fading detected by the authors was probably due to losses of electrical contact caused by periodic volume change of the anode during cycling. Table 3. Performances of Mg cells assembled with Bi and Bi0.88Sb0.12 anodes. Maximum Specific Capacity (mAh g−1) Bi 257 Bi0.88 Sb0.12 298 Specific Capacity at the 100th Cycle (mAh g−1) 222 215 Shao et al. studied the electrochemical characteristics of bismuth nanotubes (NTs), synthesized by hydrothermal reaction [161]. The purpose was to reduce the diffusion length of magnesium ions in order to mitigate the kinetic hurdles that exist in alternative anode materials. The experiments were conducted for both bismuth NTs and microparticles, in Mg(BH4)2 + LiBH4 diglyme electrolytes. Figure 7 displays the cyclic voltammograms (CV), the discharge/charge profile and the rate/cycling performances of the cells assembled by Shao et al. The results clearly showed superior performances in the case of a bismuth nanostructured anode, especially at high C rates (Figure 7c). At 5C, the specific capacity was 216 mAh g−1 for bismuth NTs vs. 51 mAh g−1 for bismuth microparticles. The former also showed narrower peaks and lower overpotential (Figure 7A), together with a faster response. At low C rates, i.e., between C/20 and C/2, the performances of the two structures were almost comparable. Furthermore, bismuth NTs were studied in a full cell setup, by choosing Mo6Se8 as cathode and an electrolyte consisting of Mg(TFSI)2 0.4 M in diglyme. A mid-point discharge voltage of about 0.75 V and a specific capacity of 90 mAh g−1 were observed. The full cell also exhibited a 92.3% capacity retention after 200 cycles (Figure 7D). X-ray diffraction (XRD) analysis confirmed the high reversibility of magnesium ions insertion. A weakness, though, was the large voltage hysteresis between magnesium alloying and dealloying, which resulted in energy losses. Other drawbacks were the exotic nature of the anodic material and its manufacturing costs, which made it difficult to be used in large scale commercial systems [110].PDF Image | Overview on Anodes for Magnesium Batteries

PDF Search Title:

Overview on Anodes for Magnesium BatteriesOriginal File Name Searched:

nanomaterials-11-00810.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |