PDF Publication Title:

Text from PDF Page: 007

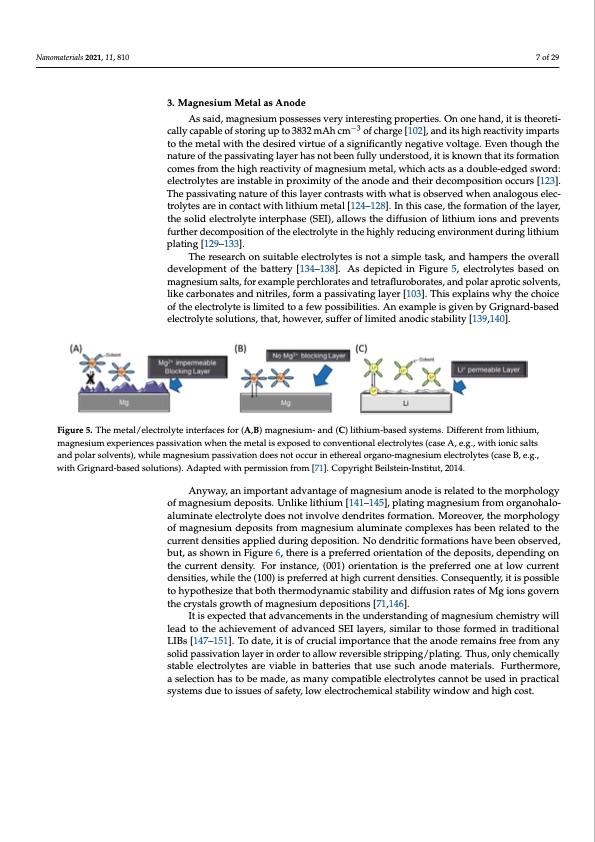

Nanomaterials 2021, 11, 810 7 of 29 , x 3. Magnesium Metal as Anode 7 of 28 As said, magnesium possesses very interesting properties. On one hand, it is theoreti- cally capable of storing up to 3832 mAh cm−3 of charge [102], and its high reactivity imparts to the metal with the desired virtue of a significantly negative voltage. Even though the [123]. The passivating nature of this layer contrasts with what is observed when analogous nature of the passivating layer has not been fully understood, it is known that its formation comes from the high reactivity of magnesium metal, which acts as a double-edged sword: electrolytes are in contact with lithium metal [124–128]. In this case, the formation of the electrolytes are instable in proximity of the anode and their decomposition occurs [123]. layer, the solid electrolyte interphase (SEI), allows the diffusion of lithium ions and pre- lithium plating [129–133]. The passivating nature of this layer contrasts with what is observed when analogous elec- vents further decomposition of the electrolyte in the highly reducing environment during trolytes are in contact with lithium metal [124–128]. In this case, the formation of the layer, the solid electrolyte interphase (SEI), allows the diffusion of lithium ions and prevents further decomposition of the electrolyte in the highly reducing environment during lithium The research on suitable electrolytes is not a simple task, and hampers the overall plating [129–133]. development of the battery [134–138]. As depicted in Figure 5, electrolytes based on mag- The research on suitable electrolytes is not a simple task, and hampers the overall development of the battery [134–138]. As depicted in Figure 5, electrolytes based on nesium salts, for example perchlorates and tetrafluroborates, and polar aprotic solvents, magnesium salts, for example perchlorates and tetrafluroborates, and polar aprotic solvents, like carbonates and nitriles, form a passivating layer [103]. This explains why the choice like carbonates and nitriles, form a passivating layer [103]. This explains why the choice of the electrolyte is limited to a few possibilities. An example is given by Grignard-based of the electrolyte is limited to a few possibilities. An example is given by Grignard-based electrolyte solutions, that, however, suffer of limited anodic stability [139,140]. electrolyte solutions, that, however, suffer of limited anodic stability [139,140]. FigFurieg5u.rTehe5.mTethael/meleectraol/yeteleincterrofalycetsefoinr (tAer,Bfa) mceasgnfoesriu(mA-,Ban)dm(Ca)glintheiusimu-mba-seadnsdyst(eCm)s.liDthififeurmen-tbfraosmedlithsiyusmt,ems. magnesium experiences passivation when the metal is exposed to conventional electrolytes (case A, e.g., with ionic salts Different from lithium, magnesium experiences passivation when the metal is exposed to conven- and polar solvents), while magnesium passivation does not occur in ethereal organo-magnesium electrolytes (case B, e.g., tional electrolytes (case A, e.g., with ionic salts and polar solvents), while magnesium passivation with Grignard-based solutions). Adapted with permission from [71]. Copyright Beilstein-Institut, 2014. does not occur in ethereal organo-magnesium electrolytes (case B, e.g., with Grignard-based solu- tions). Adapted with peArnmywisasyio, annfirmopmor[t7a1n]t.aCdvoapnytargigehotf mBeaiglnsteesiunm-Inasntoidtueti,s2r0el1a4te.d to the morphology of magnesium deposits. Unlike lithium [141–145], plating magnesium from organohalo- aluminate electrolyte does not involve dendrites formation. Moreover, the morphology Anyway, an important advantage of magnesium anode is related to the morphology of magnesium deposits from magnesium aluminate complexes has been related to the of magnesium deposits. Unlike lithium [141–145], plating magnesium from organohalo- current densities applied during deposition. No dendritic formations have been observed, but, as shown in Figure 6, there is a preferred orientation of the deposits, depending on aluminate electrolyte does not involve dendrites formation. Moreover, the morphology of the current density. For instance, (001) orientation is the preferred one at low current magnesium deposits from magnesium aluminate complexes has been related to the cur- densities, while the (100) is preferred at high current densities. Consequently, it is possible rent densities applied during deposition. No dendritic formations have been observed, to hypothesize that both thermodynamic stability and diffusion rates of Mg ions govern the crystals growth of magnesium depositions [71,146]. but, as shown in Figure 6, there is a preferred orientation of the deposits, depending on It is expected that advancements in the understanding of magnesium chemistry will the current density. For instance, (001) orientation is the preferred one at low current den- lead to the achievement of advanced SEI layers, similar to those formed in traditional sities, while the (100) is preferred at high current densities. Consequently, it is possible to LIBs [147–151]. To date, it is of crucial importance that the anode remains free from any solid passivation layer in order to allow reversible stripping/plating. Thus, only chemically hypothesize that both thermodynamic stability and diffusion rates of Mg ions govern the stable electrolytes are viable in batteries that use such anode materials. Furthermore, crystals growth of magnesium depositions [71,146]. a selection has to be made, as many compatible electrolytes cannot be used in practical systems due to issues of safety, low electrochemical stability window and high cost. 1PDF Image | Overview on Anodes for Magnesium Batteries

PDF Search Title:

Overview on Anodes for Magnesium BatteriesOriginal File Name Searched:

nanomaterials-11-00810.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |