PDF Publication Title:

Text from PDF Page: 005

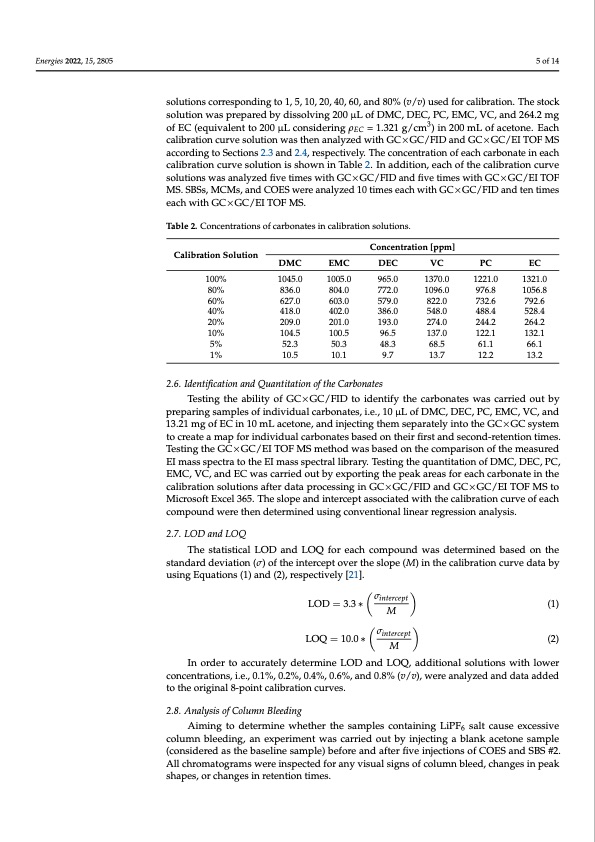

Energies 2022, 15, 2805 5 of 14 solutions corresponding to 1, 5, 10, 20, 40, 60, and 80% (v/v) used for calibration. The stock solution was prepared by dissolving 200 μL of DMC, DEC, PC, EMC, VC, and 264.2 mg of EC (equivalent to 200 μL considering ρEC = 1.321 g/cm3) in 200 mL of acetone. Each calibration curve solution was then analyzed with GC×GC/FID and GC×GC/EI TOF MS according to Sections 2.3 and 2.4, respectively. The concentration of each carbonate in each calibration curve solution is shown in Table 2. In addition, each of the calibration curve solutions was analyzed five times with GC×GC/FID and five times with GC×GC/EI TOF MS. SBSs, MCMs, and COES were analyzed 10 times each with GC×GC/FID and ten times each with GC×GC/EI TOF MS. Table 2. Concentrations of carbonates in calibration solutions. Calibration Solution 100% 80% 60% 40% 20% 10% 5% 1% DMC EMC 1045.0 1005.0 836.0 804.0 627.0 603.0 418.0 402.0 209.0 201.0 104.5 100.5 52.3 50.3 10.5 10.1 Concentration [ppm] DEC VC PC EC 965.0 1370.0 1221.0 1321.0 2.6. Identification and Quantitation of the Carbonates Testing the ability of GC×GC/FID to identify the carbonates was carried out by preparing samples of individual carbonates, i.e., 10 μL of DMC, DEC, PC, EMC, VC, and 13.21 mg of EC in 10 mL acetone, and injecting them separately into the GC×GC system to create a map for individual carbonates based on their first and second-retention times. Testing the GC×GC/EI TOF MS method was based on the comparison of the measured EI mass spectra to the EI mass spectral library. Testing the quantitation of DMC, DEC, PC, EMC, VC, and EC was carried out by exporting the peak areas for each carbonate in the calibration solutions after data processing in GC×GC/FID and GC×GC/EI TOF MS to Microsoft Excel 365. The slope and intercept associated with the calibration curve of each compound were then determined using conventional linear regression analysis. 2.7. LOD and LOQ The statistical LOD and LOQ for each compound was determined based on the standard deviation (σ) of the intercept over the slope (M) in the calibration curve data by using Equations (1) and (2), respectively [21]. σintercept LOD = 3.3 ∗ M (1) σintercept LOQ = 10.0 ∗ M (2) In order to accurately determine LOD and LOQ, additional solutions with lower concentrations, i.e., 0.1%, 0.2%, 0.4%, 0.6%, and 0.8% (v/v), were analyzed and data added to the original 8-point calibration curves. 2.8. Analysis of Column Bleeding Aiming to determine whether the samples containing LiPF6 salt cause excessive column bleeding, an experiment was carried out by injecting a blank acetone sample (considered as the baseline sample) before and after five injections of COES and SBS #2. All chromatograms were inspected for any visual signs of column bleed, changes in peak shapes, or changes in retention times. 772.0 1096.0 579.0 822.0 386.0 548.0 193.0 274.0 976.8 732.6 488.4 244.2 122.1 61.1 12.2 1056.8 792.6 528.4 264.2 132.1 66.1 13.2 96.5 48.3 9.7 137.0 68.5 13.7PDF Image | Carbonate Solvent Systems Used in Lithium-Ion Batteries

PDF Search Title:

Carbonate Solvent Systems Used in Lithium-Ion BatteriesOriginal File Name Searched:

energies-15-02805.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |